18

Dival SQD-1 - MT 234-E - 02-2020

EN

INSTALLATION

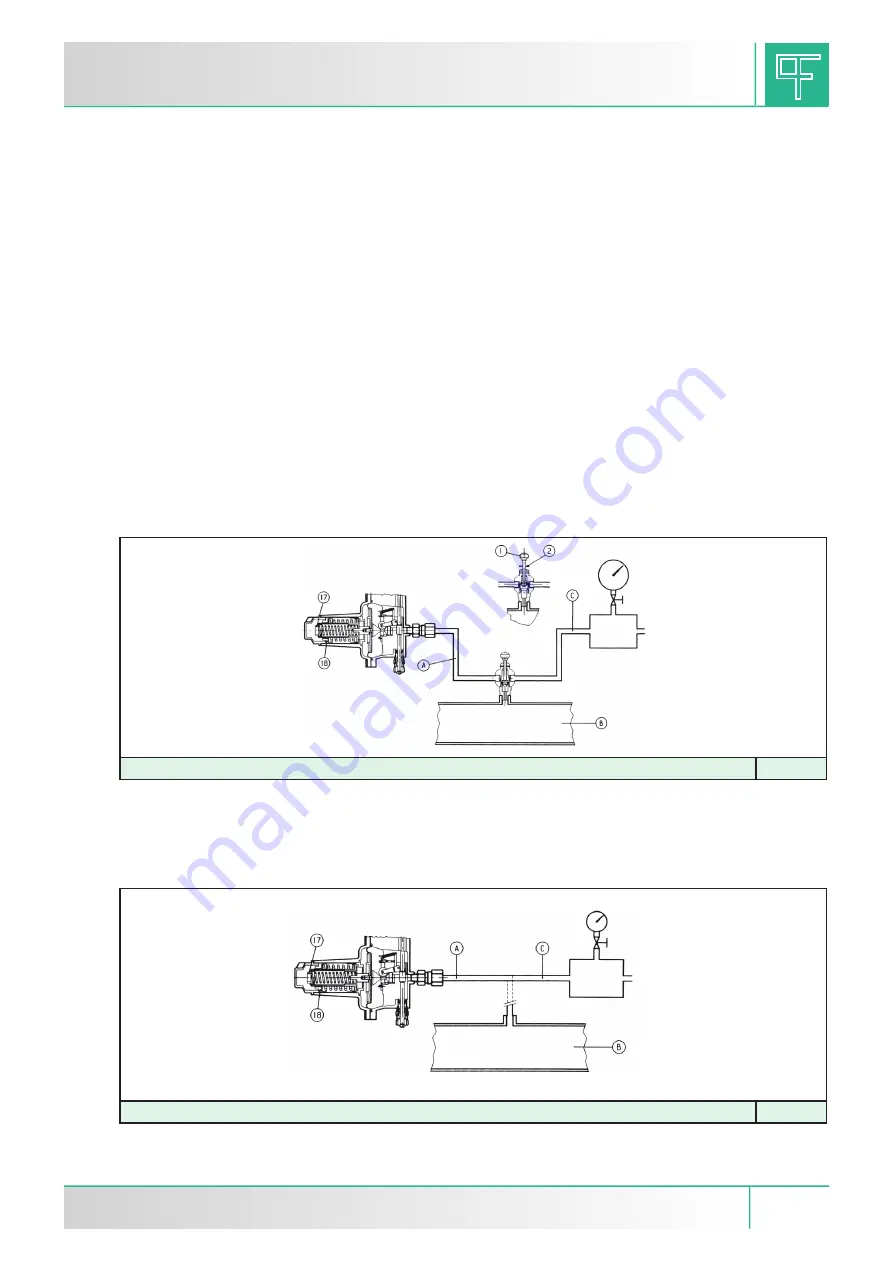

Check and adjust the intervention of the slam-shut 7 as follows:

A) For slam-shut connected to the downstream piping by a three-ways deviator “push” valve 11, (fig 14) proceed

as follows:

- connect a controlled auxiliary pressure to path C;

- stabilise this pressure at the set point established for the regulator;

- press knob 1 of the three-way “push” valve completely;

- reset the slam-shut device by means of the provided threaded bushing;

- keep the knob 1 pressed and:

• for safety devices which intervene for maximum pressure: slowly increase the auxiliary pressure and

check the intervention value. If necessary, increase the intervention value by turning the adjustment ring

18 clockwise, or anticlockwise to reduce the intervention value.

• for safety devices which intervene for pressure increase and reduction: slowly increase the auxiliary

ressure and record the intervention value. Restore the pressure to the set point established for the regula

-

tor, and carry out slam-shut reset operation.

- Check intervention for pressure reduction by slowly reducing the auxiliary pressure. If necessary, increase the

ntervention values for pressure increase or decrease by respectively turning the rings 18 and 17 clockwise

and vice-versa to reduce them.

- check proper operation by repeating the operations at least 2-3 times.

Fig. 14

B) On devices without the “push” valve (fig. 15) we recommend connecting the control head separately to a con

-

trolled auxiliary pressure and repeating the operations described above

Fig. 15

Rest position

(A and B communication)

Controll position

(A and C communication)

Cham-

ber with

controlled

pressure

Enviroment with the pressare

to keep under control

Enviroment with the pressare

to keep under control

Chamber

with control

-

led pressure