5.4 PHOTOCENTRIC STUDIO SET-UP

A 32GB

USB flash drive is supplied with your LC

Magna. On this drive you can find a license number

for Photocentric Studio. This allows you to activate

a perpetual license for up to two PCs. Photocentric

Studio can be downloaded from this

On this page, you can also find guidance on the

following:

- The minimum system requirements

for Photocentric Studio

- Installing the software

- Getting started

- Adding supports and slicing files

- Updating the software

To prepare files for printing, please follow the below

steps:

1. Upon opening Photocentric Studio, select LC

Magna/LC Magna V.2/LC Magna V.2 Fast Printing*

from the machine profile drop down menu. Then,

select the desired resin profile from the material drop

down menu, click ‘Apply’ for the software to load.

* LC Magna V.2 Fast Printing machine profile only works for

specific applications and resin. For more information, visit the

Magna V.2 Fast Printing section on the Magna resource hub.

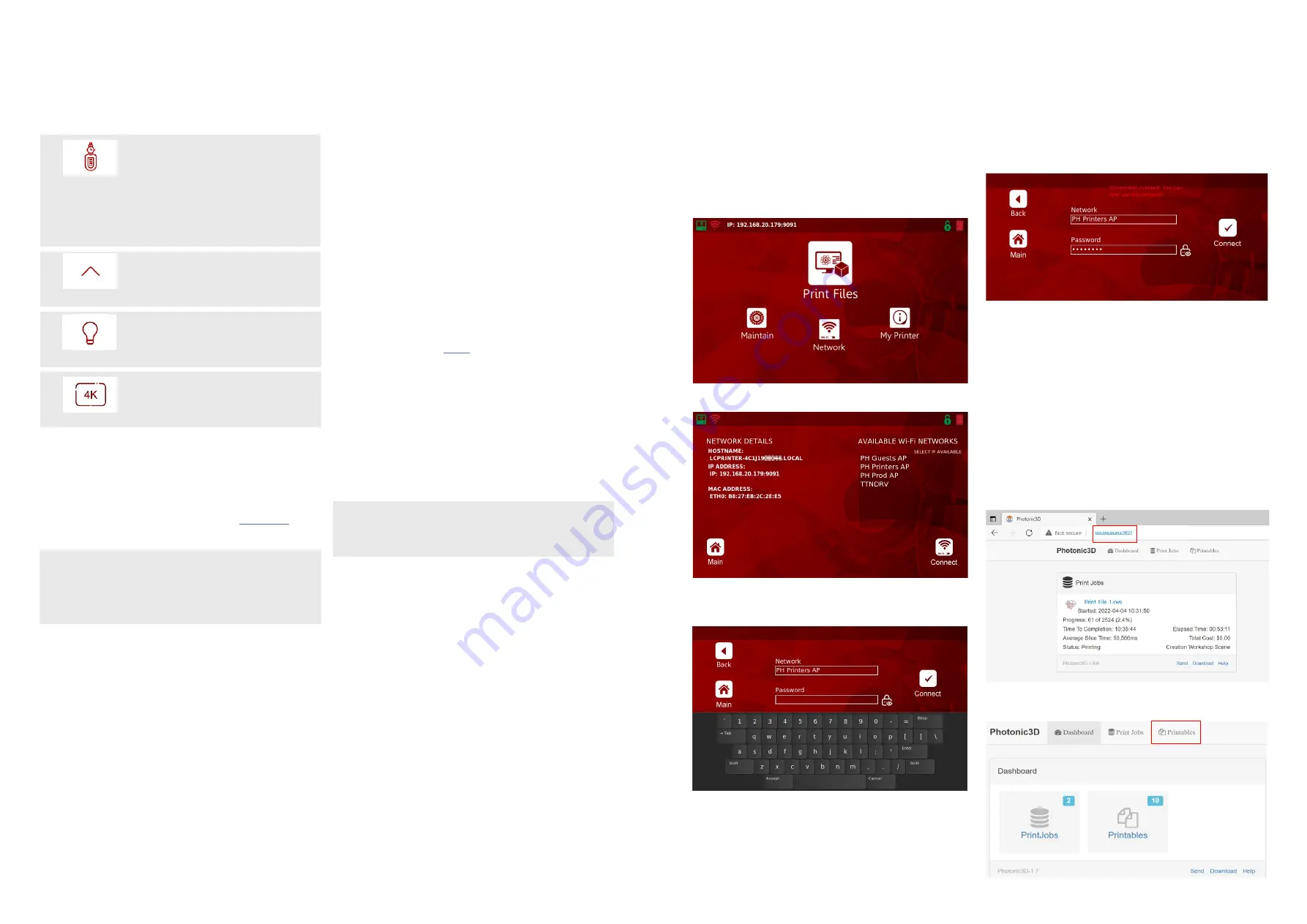

Network Page

LC Magna can be connected to a network to

facilitate the uploading and removal of print files and

to monitor prints in progress remotely.

5.5 CONNECTING TO A NETWORK

Once your Liquid Crystal Magna is switched on, plug

in the ethernet cable or Wi-Fi dongle to establish a

network connection. This allows print file uploads

and remote monitoring. These instructions are a

guide to setting up the connection and uploading a

print file.

5.5.1 Connecting to a Network via Ethernet

Switch on LC Magna using the power switch at the

front. Plug an ethernet cable into the designated

socket at the back of the printer. Once the ethernet

cable is connected, the IP address will be displayed

in the top left corner of the Main GUI page.

5.5.2 Connecting to a Network via Wi-Fi

1. Plug in the Wi-Fi dongle to the USB port at the

back of the printer.

2. On the ‘Main’ screen, select ‘Network’.

3. Select the desired network from the list.

7. Select ‘Connect’ and wait for the connection to be

established.

8. Select ‘Main’.

9. The Wi-Fi icon at the top left of the main page

should now be green. The IP address should be

displayed next to it.

4. Select ‘Connect’.

5. Select ‘Password’.

4. Select ‘Printables’ from the tabs at the top of the

screen.

6. Enter the password for this network by using the

on-screen keyboard. Password characters can be

displayed by selecting the lock icon to the right of

the text frame.

2. Import the desired file to Photocentric Studio and

support as necessary. Please refer to the Photocentric

Studio Support software videos for further guidance

by following the link

3. Once satisfied, record the resin volume required

to print from the tool panel for use when setting up

the print.

4. Slice the file and save to a specified location on

your PC.

5. Upload the file to LC Magna via USB or web

transfer.

5.6 FILE TRANSFER

5.6.1 Online File Transfer

1. Connect to a Network.

(See Section 5.5 for further guidance).

2. Open a web browser on your PC.

3. Type the printers’ IP address into the search bar.

10

9

To lift the print platform to its homing location.

Lift Platform

Once you select ‘Light On’, you can turn it

off by pressing ‘Light Off’. Or, light will go off

automatically after 10 seconds.

To check the printer screen function, select ‘Test

LCD’. Photocentric logo will be displayed in the

centre of the screen.

Light OFF

Display

NOTE:

Photocentric recommends saving the license

file locally on your PC in case the USB provided

is misplaced or damaged.

NOTE:

See Section 5.5 for further guidance on network

connection.

MAGNA

Liquid Crystal

MAGNA

Liquid Crystal

LC Magna works with patented peel release

technology called Blow-Peel. We suggest

testing the functionality of this feature weekly

and immediately after a vat leak in accordance

with maintenance schedule (Section 10). During

this procedure, air will be pumped between

the screen and vat film, causing the vat film to

inflate. The vat film should remain inflated until

the pump starts vacuuming the air out.

Pump