5.2 PRINTER SET-UP

By now and following Liquid Crystal Magna (LC

Magna) Installation Guide, the printer should have

been located in a suitable place and is now ready to

be set up.

The printer power socket is on the back of the

machine at the right-hand side. Only connect LC

Magna to the mains using the power cable provided.

Always plug the power cable into the mains socket,

then into the printer before switching on using the

power button at the front (as shown below). Similarly,

always switch off the power at the front before

unplugging the power cable from either the printer

or the mains.

Once LC Magna has been connected to power, the

foam blocks protecting the screen during shipping

need to be removed before printing.

1. Close the printer door.

2. Select ‘Maintain’ from the Main Page on the GUI.

3. Select ‘Lift Platform’ and wait for the printer arm to

reach its homing location.

4. Once the movement is complete, open the printer

door and remove the foam blocks.

5. Remove the GUI screen protector.

6. The printer is now ready to use.

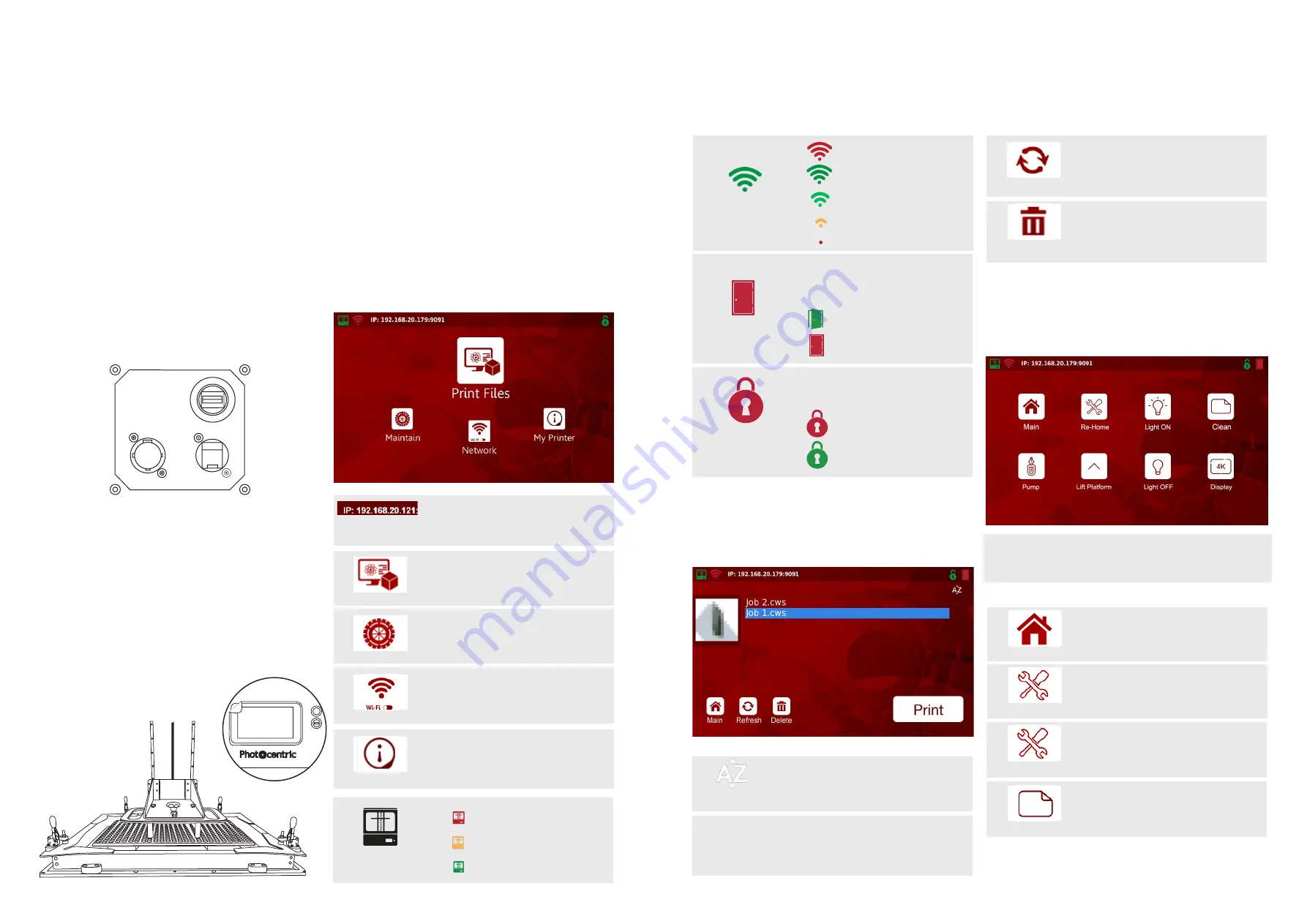

5.3 GUI INTRODUCTION

Liquid Crystal Magna GUI is the main control for

users to print, control, maintain and connect the

printer to a network.

Main Page

The ‘Main’ page is the initial display when the printer

is switched on and provides access to different

menus.

In all other menus, the option to return to the ‘Main’

page will be available.

Print Files Page

This page displays the files stored on the printer

either by online or offline transfer that are available

to print.

Maintain Page

The

‘Maintain’ page offers functions that check and

maintain printer features. It is recommended that

these features are used by or with the support of

trained personnel.

8

7

Printer System Icon

Wi-Fi

Door Switch Icon

Interlock Icon

Printer System is not ready

Printer System is launching

Printer System is up and running

No Wi-Fi Connection

Strong Wi-Fi connection

Good Wi-Fi Connection

Weak Wi-Fi Connection

Poor Wi-Fi Connection

Printer door is closed

Printer door is open

Interlock is disengaged

Interlock is engaged

Printer IP Address appears when the printer

is connected to a network. If the IP Address

is not displayed, the printer is not connected

to a network

The door switch safety feature provides

safe printing operation for LC Magna. If

the printer door is open, prints will not

start, nor will the linear drive move.

Interlock in Magna compliments the

door switch function to avoid opening

the door during mechanical movements.

To navigate through to loaded files and

initiate a print

To connect LC Magna to a Wi-Fi Network

Overview of Printer Capacity

To check and maintain printer features

Print files

Maintain

Network

My Printer

Function enables prints to be arranged

alphabetically or by chronological upload order.

Refresh button for file transfer so that files are

visible on the list.

Once selected, highlighted files can be deleted

from the printer’s memory.

List of stored files available to print. Scroll up

and down to see more. It is recommended that

files are deleted after use to best utilise printer

memory and retain processing memory for

faster performance of the GUI.

Sort

File(s) list

Refresh

Delete

Navigate back to “Main page”

LC Magna print platforms are factory calibrated

in accordance with strict QC procedures prior

to shipping. Please contact your supplier for

information on re-homing should the need arise.

The ‘Light On’ function will confirm that LC

Magna’s’ light engine is working properly. The

light engine will illuminate behind the screen for

10 seconds.

Cures a full layer of resin to assist with cleaning

the resin vat.

Main

Re-home

Light on

Clean

MAGNA

Liquid Crystal

MAGNA

Liquid Crystal

POWER

SOCKET

USB SOCKET

(FOR WIFI DONGLE)

RJ45

NETWORK

SOCKET

NOTE:

When selecting the ‘Maintain Page’ button, the LC Magna logo

on the front panel will turn from red to blue.