EN 8

3139 785 31871

2.

Measurements Setup, Service Aid & Lead Free Requirements

2.2 Service

Hints

CAUTION

CHARGED CAPACITORS ON THE SERVO BOARD MAY DAMAGE THE DRIVE

ELECTRONICS WHEN CONNECTING A NEW DRIVE.THAT’S WHY, BESIDES THE SAFETY

MEASURES LIKE

• SWITCH OFF POWER SUPPLY

• ESD

PROTECTION

ADDITIONAL ACTIONS MUST BE TAKEN BY THE REPAIR TECHNICIAN.

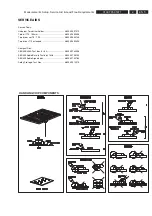

The following steps have to be done when replacing the defective loader :

1. Dismantling of the loader to access the ESD protection point if necessary.

2. Solder the ESD protection point*.

3.

Disconnect

fl exfoil cable from the defective loader.

4. Put a paper clip on the fl exfoil to short-circuit the contacts (fi g.1)

5. Replace the defective loader with a new loader.

6. Remove paperclip from the fl exfoil and connect it to the new loader.

7. Remove solder joint on the ESD protection point.

ATTENTION: The laser diode of this loader is protected against ESD by a solder joint which shortcircuits the laserdiode to ground.

For proper functionality of the loader this solder joint must be remove

after

connection loader to the set.

Type 1

Type 2

(ESD protection point is accessible from top of loader)

(ESD protection point is accessible from bottom of the loader)

*Only applicable for defective loader needed to be sent back to supplier for failure analysis and to support backcharging

evidence.

This is also applicable for all partnership workshops.