4 .

G Y 5 0 1 r e m o v a l

Remove the main metal side plate (6 screws). Loosen the four

screws securing the top plate together with the valve base, then

remove the screw securing the white insulator to the metal bracket.

Turn the insulator in the two slots until the hole on the captive

side lines up with the head of the fixing rivet, then withdraw the

insulator. Lift out the GY501 valve from the E.H.T. overwind

holder, then withdraw it from the base.

5 .

Line transformer bobbin removal

Remove the main metal side plate (6 screws), and the PD500 and

GY501 valves. Unsolder the E.H.T. lead from the valve holder,

and remove the two plugs from the sockets mounted on the side

plate below the printed panel. Unsolder the four leads from the

tag panels, then remove the four bobbin fixing screws from under-

neath the transformer, allowing the bobbin to be withdrawn through

the bottom of the chassis. When fitting a new bobbin, ensure that

the leads and plugs are replaced correctly, and that the E.H.T.

';,,lead has a smooth soldered joint where it is connected to the valve

,base.

Note.

It is essential that the round metal plate on the top cover

shielding V5003 valve base is always refitted correctly after servicing

the

L.O.P.T.

assembly.

Line transformer fault-finding

The line transformer must not be operated with the screening

cover removed. However, all the tappings on the line trans-

former windings are available externally, via the two 10-way

sockets mounted on the side of the E.H.T. can assembly, and

connections to many components can be made either on the

printed panel or within the valve compartment of the assembly

once the gauze screen has been removed. In cases of arcing due to

breakdown of a component inside the assembly, it may be first

necessary to try to locate approximately where the fault has oc-

curred by noting if any damage is apparent. After replacement of

the line transformer bobbin or any component which has failed

due to breakdown, engineers should ensure that the line output

circuit is operating normally since the breakdown could well be

the symptom of another fault.

The following points should be borne in mind when servicing the

L.O.P.T. assembly.

1.

Boost voltage measurement (590V) gives an immediate know-

ledge of drive to the transformer. Unless the deflection coil

circuit has a fault, normal boost implies correct primary

operation.

2.

A very low boost voltage must indicate either a heavy load on

the line transformer such as a shorted turn, or no drive to the

transformer e.g. open-circuit or no emission in the PL509 or

PY500 valves.

3.

If the boost voltage is fairly normal, then scanning current

exists and the absence of a raster must indicate lack of an

electrode voltage on the C.R.T.

4.

Grid and cathode voltage measurements on the PD500 valve

are very revealing for faults in the shunt stabilising circuit.

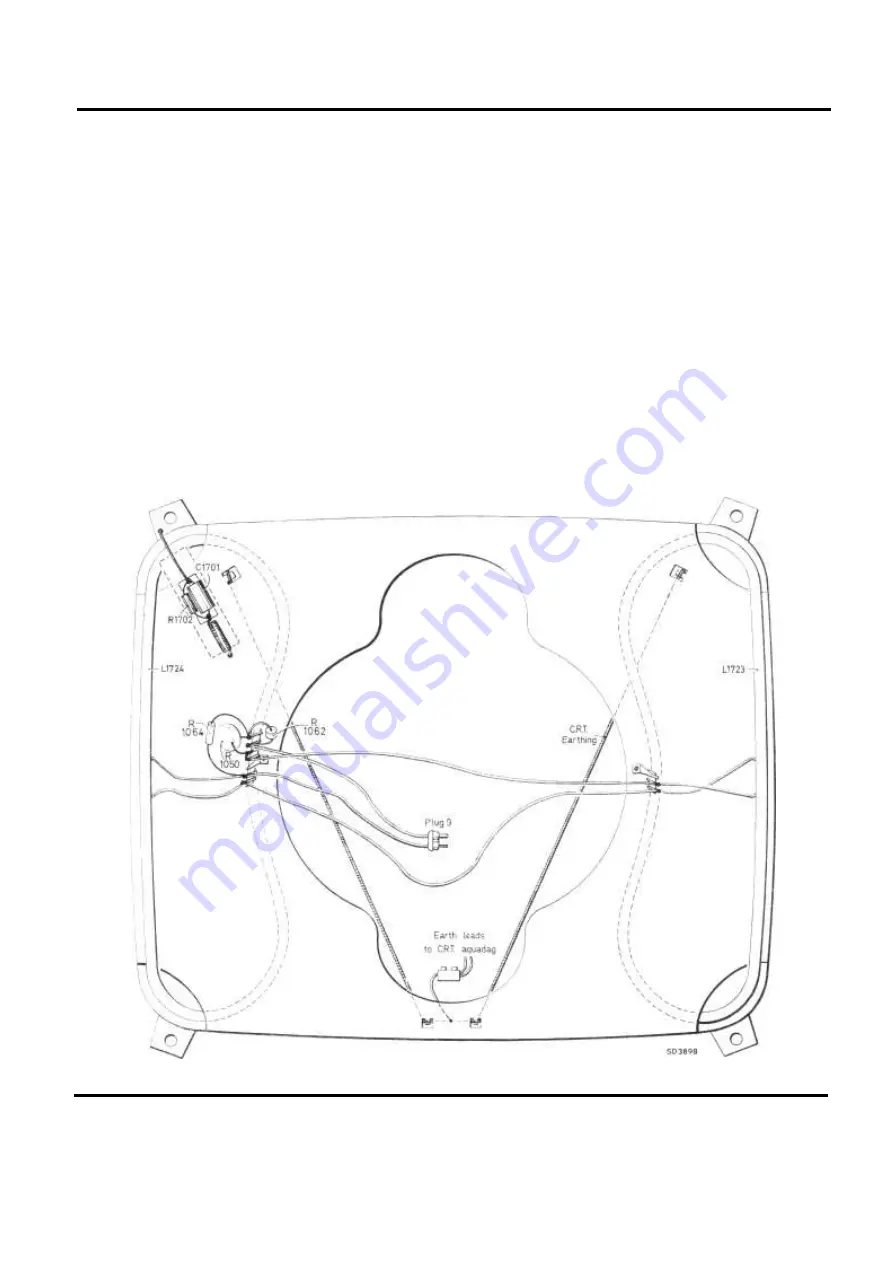

Fig . 4 . C. R. T. shiel d

Page Seven

Summary of Contents for G22K511

Page 3: ...G22K511 G25K512 Page Two ...

Page 12: ...Page Ten ...

Page 14: ...Page Eleven ...

Page 19: ...Page Fifteen ...