J - GREY SCALE TRACKING

Dark grey tones

1.

Check that the setting of R7285 is correct (see "Preset adjust-

ments" section H, para. 17).

2.

Disconnect the luminance feed to the C.R.T. and unplug the

I.F. lead from the tuner.

3.

Switch off the red and green guns (switches 18 and 19) and

adjust control (14) until the blue raster is barely visible.

4.

Switch off blue (17) and switch on green (18).

5.

Adjust control (15) until the green raster is barely visible.

6.

Switch off green (18) and switch on red (19).

7.

Adjust control (16) until the red raster is barely visible.

8.

Switch on blue and green guns (17 and 18) and reconnect the

luminance and I.F. leads.

9.

Tune in to a monochrome picture, preferably a stepped

"staircase" pattern containing shades of grey. Check that the

picture has a good neutral grey tone and, if necessary, slightly

readjust any two "G2" controls (14, 15 or 16) to obtain the

correct tone.

White tones

The controls for the setting of the "white tones" in the grey-scale

tracking adjustments require careful setting up which is achieved

during the manufacture of the receiver. The following instructions

are given for guidance since it is necessary to use special test

equipment to obtain precise results.

10.

Using the transmitted picture, adjust R1077 and R1080 (see

Fig. 5) for a neutral white.

K - COLOUR DIFFERENCE OUTPUT ADJUSTMENTS

Firstly check that the grey scale tracking has been correctly set.

1.

Switch to colour bars and adjust controls for normal contrast

and colour.

2.

Switch off red and green guns, and check that the four blue

bars are of equal brightness. If necessary, readjust the contrast

and colour controls. When this check is complete, do not

disturb the front controls until adjustments 3 and 4 are

complete.

3.

Switch off the blue gun and switch on the red. Adjust R7173

for equal brightness of four red bars.

4.

Switch off the red gun and switch on the green. Adjust R7245

to balance the brightness of bar 3 with bars 2 and 4. Then

adjust R7236 to equalise the brightness of bar 1 and bar 4.

Repeat the adjustments of R7245 and R7236 until all 4 green

bars have equal brightness.

L - I.F. ALIGNMENT

1. General

All coils are carefully trimmed and sealed during manufacture.

Normally, complete I.F. alignment should not be necessary, but in

the event of coil replacement, however, some readjustment may be

required and for this reason trimming instructions are given. It

should be noted that most replacement coils are pre-trimmed, and

if any readjustment is required on fitting, this should only

be

slight.

In all cases of trimming, the peak with the core nearest the top of

the former (i.e. away from the printed panel) should be chosen.

Alignment information is given only for a sweep generator method,

and a list of necessary equipment is shown below. A warm-up

period of at least 20 minutes should be allowed for thermal stabi-

lisation of both receiver and test equipment. Leads should be as

short as practicable in order to have least effect on the response

curve. When the sweep generator is connected to the various

injection points stated, the terminating pad shown in Fig. 9 should

be used.

The adjustment of certain vision I.F. coils will affect both luminance

and chrominance response curves. Consequently, a double beam

oscilloscope is recommended in order that both curves may be

observed simultaneously. In the event of double beam facilities not

being available however, a single beam 'scope' may be used but

frequent checks of both response curves should be made during

alignment. To avoid stray pick-up from the time bases, remove

FS1109 and the deflection coil plug (plug 6) before proceeding

with alignment.

2. Test equipment required

The following test equipment is essential in order to carry

out the

alignment operations :-

(a)

A V.H.F. sweep generator (3-42MHz) with deviation

variable 0-12MHz, together with an R.F. marker generator.

(b)

An oscilloscope (preferably double beam) for use in conjunc-

tion with the sweep generator.

(c)

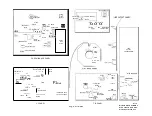

Sweep generator terminating pad as shown in Fig. 9.

(d)

Detector unit as shown in Fig. 11.

(e)

Damping unit-1.5KpF capacitor in series with 470 resistor.

(f)

Combined detector and damping unit as shown in Fig. 10.

(g)

6v. battery for bias source.

Fig. II. Detector unit

Test points

Luminance detector - oscilloscope between L2635 and

chassis.

Chrominance detector-oscilloscope between tag 5 of "CAN

E" and chassis.

Sound inter-carrier I.F. response - oscilloscope between

R2073/122524 and chassis.

Sound inter-carrier I.F. "S" curve - oscilloscope between

R2072/C2022 and chassis.

3rd vision I.F.-collector of T2143.

Chroma. bandpass-oscilloscope to R7156/R7159 and

chassis via detector unit shown in Fig. 11.

Tuner I.F. injection point-remove the tuner from the

cabinet (see section F, para. 4). Remove the _screw which

couples the switch bar to the push-button mechanism, then

push the switch bar into the tuner to its fullest extent in

order to engage the I.F. test position, and fully depress the

second push-button (from the tag strip side). Access to the

I.F.

injection point is now achieved by inserting a suitably

insulated metal probe into the hole in the mounting plate

adjacent to the second push-button. When reconnecting

the switch bar to the mechanism, set the second button to

the,`4-5 ' position and depress. Pull out the switch bar to its

fullest extent and refit the screw, making sure the coupling

bracket is held against the shoulder of the switch bar, which

should now be held fully extended and under tension.

Chassis

503402

I•SKP

47

w

v

-

o-

To TP7

75

8)K p

I

-1"

◼

7) T

UN

EIR

CHASSIS

Fig. 9. Terminating pad

R7156/ R7159

0A81

100K

1K5p

To

oscilloscope

SD3934

1.5Kp•

Collect

or

of

32163

•

Chasss

0A81

SD3935

Fig. 10. Damper/detector unit

To

Oscilloscope

3.

TP1

TP2

TP3

TP4

TP5

TP6

TP7

Page Twelve

Summary of Contents for G22K511

Page 3: ...G22K511 G25K512 Page Two ...

Page 12: ...Page Ten ...

Page 14: ...Page Eleven ...

Page 19: ...Page Fifteen ...