22

Go to cover page

200P7 LCD

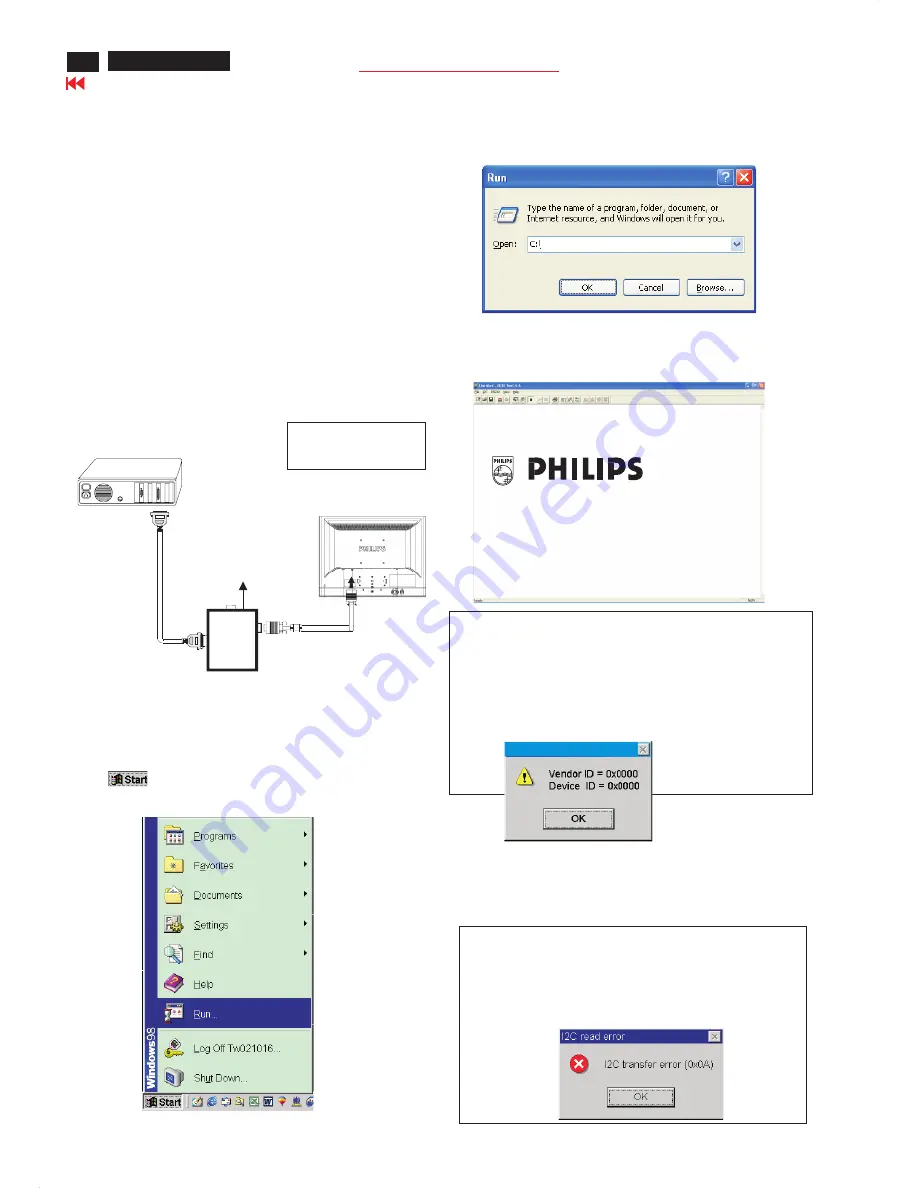

Step 3: Installation of EDID45.EXE

Method 1: Start on DDC program

Start Microsoft Windows.

1. The

P

rogram"E

D

I

D

45.EXE" in service manual cd-rom be copyed to

C

:\ .

2

.

C

lick

, choose Run at start menu of Windows as shown

In Fig. 6.

Fig. 6

4.

C

lick

button. The main menu appears (as shown in Fig. 8).

OK

This is for initialize alignment box.

Fig. 8

Fig.

7

Fig. 9

Note 1: If the connection is improper, you will see the following error

message (as shown in Fig. 9) before entering the main menu.

Meanwhile, the (read E

D

I

D

) function will be disable. At this

time,

please make sure all cables are connected correctly and

3. At the submenu, type the letter of your computer's hard disk drive

followed by :E

D

I

D

45 (for example,

C

:\E

D

I

D

45, as shown in Fig.

7

).

Note

2

:

D

uring the loading, E

D

I

D

45 will verify the E

D

I

D

data which just

loaded from monitor before proceed any further function, once

the data structure of E

D

I

D

can not be recognized, the following

error message will appear on the screen as below.

P

lease

confirm following steps to avoid this message.

1. The data structure of E

D

I

D

was incorrect.

2

.

DDC

I

C

that you are trying to load data is empty.

3. Wrong communication channel has set at configuration setup

1

Configuration and procedure

There are 3 chips contained OS

D

string, serial number..etc

on the circuit board, main EE

P

ROM which storage all factory settings,OS

D

string.

DDC

I

C

which storage 1

2

8byte E

D

I

D

data(serial number ..etc.).

Following descirptions are the connection and procedure for Analog

/

D

igital and main EE

P

ROM can be re-programmed along with

Analog/

D

igital I

C

by enable factory memory data write function on the

DDC

program (E

D

I

D

45.EXE).

Initialize alignment box

In order to avoid that monitor entering power saving mode due

to sync will cut off by alignment box, it is necessary to initialize

alignment box before running programming software

(EDID45.EXE). Following steps show you the procedures and

connection.

Step 1: Supply 8-1

2

V

DC

power source to the Alignment box by

plugging a

DC

power cord or using batteries.

Step

2

:

C

onnecting printer cable and

D

-Sub cable of monitor as Fig. 5

Fig. 5

PC

1=

P

ower connector

2

=

D

-SUB/

D

VI connector

T

o

printer

port

(

L

T

P

1)

DC P

ower

8-1

2

V

Fig. 1

0

P

rinter

P

ort

To Monitor

To

PC

2

----->

1

----->

Edid45.exe

Edid45.1

DDC

Instructions

Summary of Contents for 00P7EB/27

Page 37: ...37 200P7 LCD Go to cover page Wiring Diagram 1 14 1 2 29 30 1 1 11 11 1 6 1 8 ...

Page 39: ...39 200P7 LCD Go to cover page ...

Page 40: ...Go to cover page 200P7 LCD 40 ...

Page 41: ...41 200P7 LCD Go to cover page ...

Page 42: ...Go to cover page 200P7 LCD 42 ...

Page 43: ...43 200P7 LCD Go to cover page ...

Page 44: ...Go to cover page 200P7 LCD 44 ...

Page 45: ...45 200P7 LCD Go to cover page ...

Page 46: ...Go to cover page 200P7 LCD 46 ...

Page 47: ...47 200P7 LCD Go to cover page ...

Page 48: ...Go to cover page 200P7 LCD 48 ...

Page 49: ...49 200P7 LCD Go to cover page Power PCB C B A ...

Page 50: ...Go to cover page 200P7 LCD 50 ...

Page 51: ...51 200P7 LCD Go to cover page ...

Page 52: ...Go to cover page 200P7 LCD 52 ...

Page 53: ...53 200P7 LCD Go to cover page ...

Page 54: ...Go to cover page 200P7 LCD 54 ...

Page 56: ......

Page 57: ...57 Go to cover page 200P7 LCD ...

Page 103: ...103 200P7 LCD Go to cover page Power Diagram 200P7MG 00 ...

Page 104: ...Go to cover page 200P7 LCD 104 Power 1 200P7MG 00 C B A ...

Page 105: ...105 200P7 LCD Go to cover page Power 200P7MG 00 Power C B A 2 ...

Page 106: ...Go to cover page 200P7 LCD 106 Power 1 200P7MG 00 C B A ...