26

ROUTINE MAINTENANCE

Replacement of fluorescent lamp

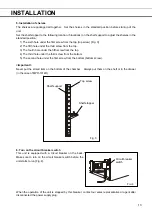

Follow the procedure below when replacing a fluorescent lamp. The fluorescent lamp is located

vertically at the back of the center mullion. [Fig. 1]

1.

Turn off the light switch and disconnect the power

supply plug of the refrigerator.

2.

Move the stored items on the left shelves to the right

shelves (right drawers for MPR-1014R). Then remove all

shelves on the left side.

3.

Pull the fluorescent lamp backwards from the clip

together with the lamp cover and wiring.

4.

After remove the water-proof cover, remove the cap with

the wiring on the both sides of the lamp cover.

5.

Take out the fluorescent lamp from the lamp cover and

insert a new fluorescent lamp in it.

6.

Replace the cap with the wiring and

the water-proof

cover on the both sides of the lamp cover.

7.

Replace the lamp cover to the clip (2 locations).

8.

Replace the shelves on the left side and return the stored items.

9.

Connect the power supply cord to the outlet and check the fluorescent lamp is turned on.

Replacement of glow starter

The glow starter is located on the top front in the chamber (upper left of the fluorescent lamp). [Fig. 1]

1.

Turn off the light switch and disconnect the power

supply plug of the refrigerator.

2.

Remove the water-proof cover and replace the glow

starter. (glow starter; FG-4P)

3.

Replace the water-proof cover.

4.

Connect the power supply cord to the outlet and check

the fluorescent lamp is turned on.

Glow starter

Fig. 1

Fig. 1

Fluorescent lamp

Clip

Summary of Contents for MPR-1014 Series

Page 2: ......