A

‐

scan

mode:

This interface allows you to see the present thickness value and the A‐scan waveform at

the same time. The right side of the interface is the specification adjusting area, which can be adjusted

for a more precise result. The detailed introduction can be seen in chapter 3.5.

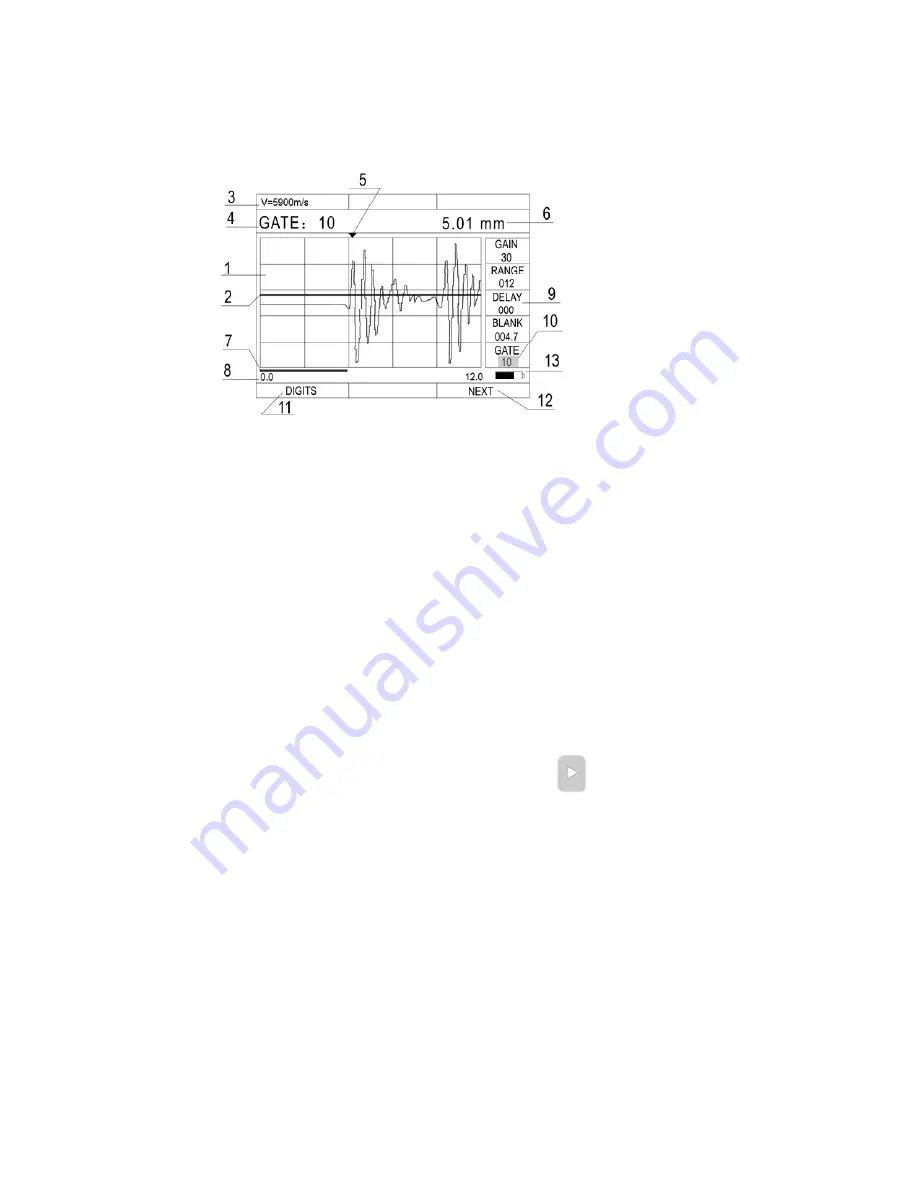

3.7 A‐SCAN MODE INTERFACE

1—waveform display area 2—gate 3—material velocity 4—the present highlighted

specification 5—measuring point( the first point of intersection between the waveform and the gate)

6—the present thickness value 7—the blank confines

8—the range confines 9—the specification adjusting area 10—highlighted signal

11—digit mode 12—specification switch 13—battery power

ATTENTION:

When the probe and the object are not completely coupled, the letters in the various

interfaces are shown in

GREEN,

when properly coupled, they are displayed in

WHITE

color and when

the either the upper or lower limits are exceeded, the letters are displayed in

RED

color.

3.5

ADJUSTING

THE

SPECIFICATIONS

IN

A

‐

SCAN

INTERFACE

In the A‐scan interface, press the bottom right button NEXT to highlight the value to be adjusted.

Then press the direction keys to adjust the values. Up and down keys are used for small increments,

while left and right for larger increments.

GAIN

—adjust the sensitivity of the gage with unit dB. The larger the gain is, the higher the sensitivity is.

The gain ranges from 8 to 55dB.

RANGE

—adjust the testing range that the screen displays. The range is 0.393” to 5.70” (10~145mm).

DELAY

—shown at the beginning point of the screen. The waveform will move horizontally when

adjusting this value.