PFT Air Compressor LK

402 IV

Overview – Operation – Spare

Parts Lists

Page 28

28.01.2019

6.5 Half-yearly oil change

Fig. 16: Oil changes

Change the oil:

To do this, pull out the oil level dipstick, loosen screw

A

(Fig. 16) and allow

the oil to flow into a container. Screw screw

A

back on and fill until the

maximum level is reached. The required oil quantities are taken from

the data table supplied with the instructions.

Oil pollutes the environment. For disposal, contact the responsible authority.

6.6 Cleaning

Fig. 17: Cleaning

Clean all ribbed parts of the compressor.

This keeps the cooling system efficient and extends the service life of

the machine.

Fig. 18: Cleaning

Every 2 years:

• Check the non-return valve and replace the sealing element D if necessary.

• Check the suction and discharge valves.

6.7 Maintenance program

Maintenance task

Every week

Every month

Every 6 hours

Every year

Oil level check

X

Condensation drain

X

Cleaning the suction filter

X

General cleaning of the compressor

X

X

Oil changes

X

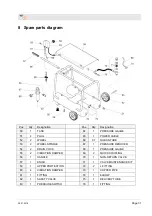

Summary of Contents for LK 402 IV

Page 35: ...28 01 2019 Page 35...