Mixing pump RITMO L / RITMO M Overview - Operation

Brief description

2016-02-17

25

Fig. 28: Suction strainer with filter screen

The end of the suction line (3) has to be equipped with a suction

strainer with filter screen and built-in non-return valve.

We recommend an additional filter for fine particles in the suction

line.

NOTE!

The flow rate of the pump decreases with

increasing length of the suction line. Connect the

booster pump as close as possible to the water

sampling point (pressure is better than suction).

If all these points have been observed, the pump can be switched

on. Depending on the length of the suction line, the suction time

can be up to a couple of seconds. If the pump does not deliver

after a brief period, this might be due to the following reasons:

There is still air in the pump and it has to be vented completely

once again.

The suction line has a leak and the pump draws air.

The suction strainer is clogged.

There is a kink in the suction hose.

The maximum suction height is exceeded.

Caution!

The pump must not run dry to avoid any damage.

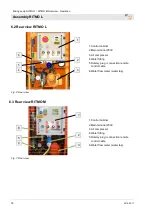

18 Brief description

The compact mixing pump RITMO L / RITMO M with 230V AC

drive was specially developed for pumping, spraying and applying

of dry mortar, pasty materials for machine use and much more up

to 2 mm grain size.

The pump output can be continuously adjusted electronically

depending on the requirements.

The machine consist of portable individual components which allow

quick and comfortable transport with handy dimensions and less

weight.

3