Pr

epar

ations

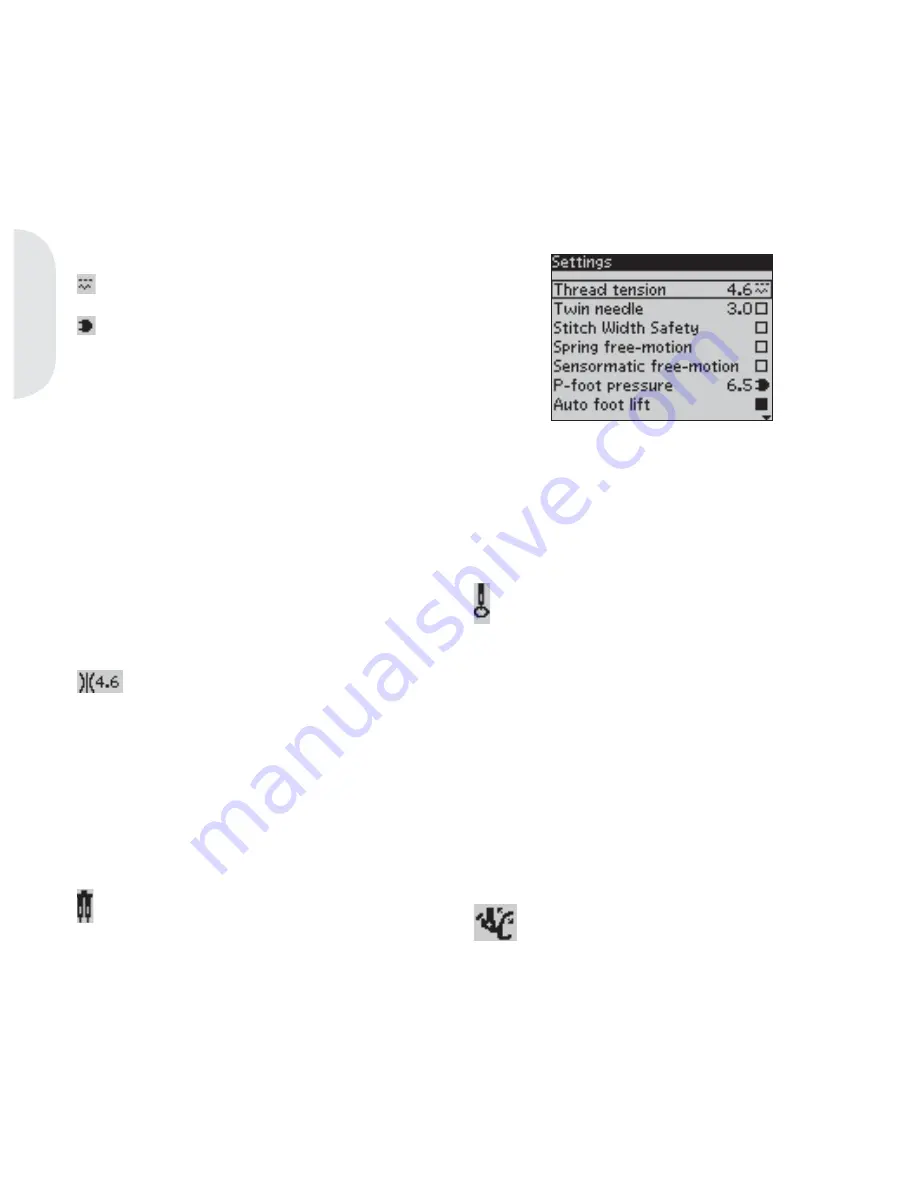

Settings menu

In the settings menu, you can override default settings and make manual adjustments to the machine

settings, sound settings and screen settings.

Open the menu by pressing the settings menu button and select the setting you wish to adjust by

pressing the up and down arrow buttons on the wheel.

Use the left and right arrow buttons to adjust the values and activate settings or open a list of choices by

pressing OK. A

À

lled box means it is activated, an empty box means it is not activated.

Note: If a setting cannot be combined with a previously selected setting, the outlines of that box will be dashed.

There are two icons which are shown next to some

of the setting alternatives.

This icon shows you that the setting will be

kept until you select another stitch.

This icon shows you that the setting will be

kept until you switch your machine off.

No icon means that this setting is kept until you

deactivate it.

Press the settings menu button again to leave the

settings menu.

Thread tension (4.0)

Your sewing machine will electronically pre-set a

thread tension for the selected stitch. Depending

on the fabric, batting, thread etc, the tension may

need to be adjusted. Use the left and right arrow

buttons on the wheel to adjust the thread tension.

The changes only affect the selected stitch. The

setting will go back to default when you select

another stitch.

In sewing mode, press the info button to

see the current selected thread tension.

For 3.0 and 2.0:

See page 3:2 for instructions on

how to set the thread tension.

Twin needle (4.0 and 3.0)

Activate the twin needle program and use the left

and right arrow buttons on the wheel to set the

twin needle width. When a twin needle size is

selected, the width of all stitches is limited for that

needle size to prevent needle breakage.

In sewing mode, press the info button. The twin

needle recommendation icon will be shown.

The setting is kept until you deselect the twin

needle setting.

Note: Twin needle and stitch width safety cannot be

used at the same time.

A warning pop-up will be shown if you select a stitch

that is too wide for the set twin needle size.

Stitch width safety (4.0 and 3.0)

Select this function when using a straight stitch

needle plate or a straight stitch presser foot to lock

the center needle position for all stitches to prevent

damage to the needle, presser foot or needle plate.

In sewing mode, press the info button. The

stitch width safety icon will be shown.

When turning on the machine with this setting

activated and for every stitch selection that is not

a straight stitch, a pop-up informs you that it is set

to straight stitch. Deselect stitch width safety to go

back to normal sewing.

Note: Twin needle and stitch width safety cannot be

used at the same time.

Spring foot free-motion (4.0)

Activate to set the machine in spring foot free-

motion mode. Lower the feed dogs. A spring foot

will raise and lower with each stitch to hold the

fabric on the stitch plate while the stitch is being

formed.

In sewing mode, press the info button. The

spring foot free-motion icon will be shown

instead of the presser foot recommendation.

A pop-up will inform you that spring foot free-

motion is active when turning on the machine.

Note: The open toe free-motion foot is optional and can

be purchased at your local authorized PFAFF® dealer.

Do not use if sensormatic free-motion is activated, since

the needle might damage the presser foot.

The open toe free-motion foot, or any spring foot with

light grey plastic housing, can also be used for free-

motion embroidery.

2:16

Summary of Contents for expression 2.0

Page 1: ...Owner s manual...

Page 12: ...Preparations...

Page 21: ...Preparations...

Page 30: ...Sewing...

Page 40: ...Sequencing...

Page 44: ......