© Pertronic Industries Ltd

8

FAAST LT Loop-Based Installation & Maintenance Guide Iss 1.0, 201701

2

3

1

3

4

5

6

2

1

IO

N

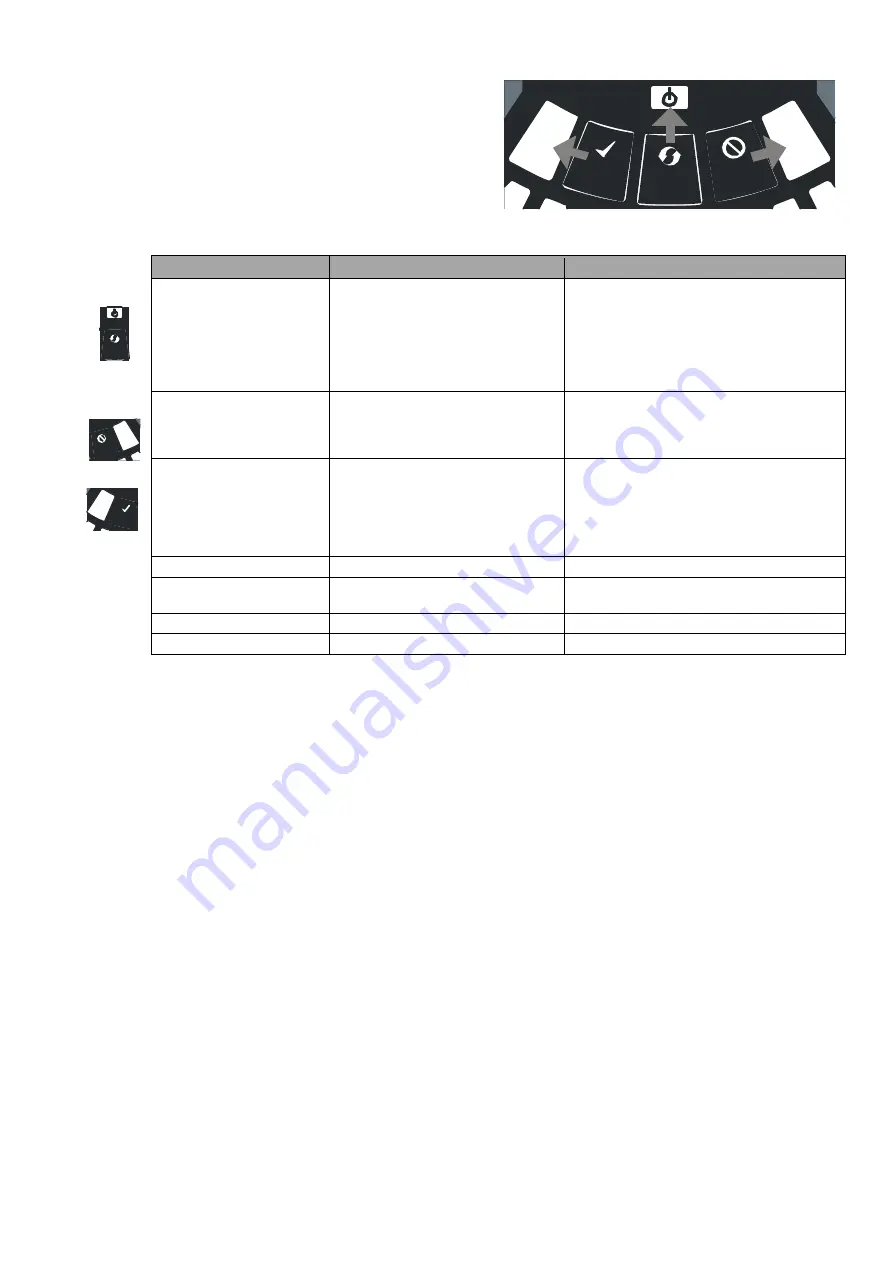

Front Panel Buttons

The front panel has three (3) user buttons:

TEST

,

RESET

and

DISABLE

These buttons are used to enter the pass-code which then

allows

simple test functions to be performed.

Note: In Remote Maintenance and Service Mode these

buttons

are disabled.

Table 5: Front Panel Buttons

BUTTON

NORMAL Mode

MAINTENANCE Mode

RESET

Press for 2s to start PASSWORD

PROCEDURE to enter

MAINTENANCE

mode

Press for 2s to Reset latched Alarms, Faults

and

sounders (relays).

Alarm controlled by panel: if the

Alarm

persists, set again immediately after the Reset

In DISABLE Mode, press for 2s to exit from

DISABLE Mode (but remains in

MAINTENANCE Mode)

DISABLE

Use to increment Password digits in

PASSWORD PROCEDURE

Press for 2s to enter DISABLE Mode for

60

minutes (default).

Alarms, Alerts and Faults not reported

(To exit DISABLE Mode see RESET)

TEST

Use to confirm password in

PASSWORD

PROCEDURE.

Default Password = 3111

Press for 2s then release - both detectors will

simulate Alarm

Press for 4s then release

– Detector #1 will

simulate Alarm

Press for 6s then release

– Detector #2 will

simulate Alarm

COMBINATIONS

RESET + DISABLE

Press for 2s to show Fan Speed

(on

Smoke Level scales) for a preset time

Press for 2s to show Fan Speed

(on Smoke

Level scales) for a preset time

RESET + TEST

No action

Press for 2s to turn Sounders OFF

RESET + TEST + DISABLE No action

Press for 2s to exit MAINTENANCE mode

Password Sequence to Enter MAINTENANCE mode

a) press and hold

RESET

; Left Flow indicator turns yellow, then green

b) release

RESET

and

FAULT

indicator turns ON (green). The

left Flow indicator blinks green indicating the

device is ready for

the first digit

c) press

DISABLE

to increment the LEDs 1…9; press

TEST

to select a digit

The flashing airflow segment turns ON (green) and the next segment begins to flash indicating set the next digit.

When the 4th digit is selected, all 4 airflow segments turn OFF.

- if the password is accepted the

FAULT

indicator remains green and

the unit enters

MAINTENANCE

mode.

- if the password is incorrect, the

FAULT

indicator flashes yellow and the unit remains in

NORMAL

mode.

The default Password is

3111

If no button is pressed for 10s during the password sequence, the

unit returns to

NORMAL

mode.

If there is no activity in

MAINTENANCE

mode for 5 minutes (default), the

FAULT

indicator blinks green for

15secs and then the unit returns to the

NORMAL

state.

TESTING:

Note that the Laser detector LEDs, which are controlled by the Fire Panel, must be turned ON to activate the front

panel Alarm

indicators

Magnet Test:

The alarm signalling can be tested for functionality by placing a

test magnet in the position shown in Figure 10

(refer Page 4). This method does not test the air flow in the pipe-work

Smoke Testing:

The system alarm response can be tested for functionality

using smoke. The choice of smoke source is

dependent on the

installation but Pertronic industries recommends the use of a Smoke Pen (PN: SMOKEPEN)

In all cases the smoke must be present for the

duration of the test.

Smoke pellets or matches can be used close

to the sampling point to introduce smoke particulates into the

system. It is recommended that smoke with a particulate life cycle

of greater than 120 seconds should be used

–

standard aerosol sprays for

point detector testing do not work well on aspirated systems and therefore a re not

recommended.

Fault Testing:

Simulate a fault on the detector (for example, block the outlet pipe)

and check that a fault is signalled on both the

front panel of the unit

and at the Fire Panel.