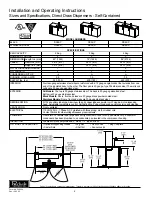

Form No. Z2025A

Rev. 12.05.03

3

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

Preparing the Cabinet for Use

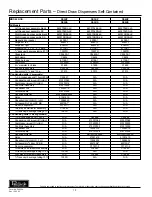

–

Direct Draw Dispensers Self-Contained

Parts List

■

Faucet Standard.

■

Faucet Head Assembly.

■

Black Connector Hose

3

⁄

16

” x 3’.

■

5

⁄

16

” Air Hose.

■

Spanner Wrench.

■

Bag of Miscellaneous Parts.

Tools Required

■

#2 Phillips Screwdriver.

■

Spanner Wrench (included).

■

#10 Crescent Wrench.

■

9

/

16

” Allen Wrench.

■

3

/

8

” Nut driver.

■

Power Screwdriver (

if available).

Uncrating and Inspection

Remove all crating material before operating.

Carefully inspect cabinet for hidden damage. If

damage is discovered, file your claim immediately

with the transportation company. Perlick is

not responsible for damage in transit.

Placing the Cabinet

Push the cabinet into place using rollers when

necessary.

Leveling the Cabinet

When the cabinet is in place, check installation with

a carpenter’s level. A slight pitch to the drain side is

desired. Water may accumulate if the cabinet is

pitched to the opposite side.

Installing Casters or Legs (Optional)

Attach casters to the cabinet bottom in the holes

provided. Use supplied

1

/

4

”- 20 x

3

/

4

” hex head

self-tapping machine screws. Use power driver if

available.

Installing the Faucet and

Dispensing Head

Before you begin: Wash tapping devices and

faucet. Flush beer, tapping device and faucet lines

with fresh water.

■

Apply RTV around the base of the dispensing

head to seal it to the top. Align the dispensing

head over the holes on the cabinet top and use

screws provided to secure standard to cabinet

top. Wipe off excess RTV to complete the seal.

■

Attach faucet to standard using spanner

wrench to tighten coupling. Attach faucet

handle to faucet.

■

Insert flexible plastic air hose six to seven

inches into bottom of faucet standard.

Secure hose with tie wrap (supplied).

Plumbing

The floor drain in the right rear corner is equipped

with a

3

/

4

” female pipe thread connection with side or

bottom access for beer drainer waste.

■

Remove either side or bottom drain plug with an

allen wrench and attach a

3

/

4

” male pipe (provided

by plumber) to an external drain connection.

Evaporator condensate has been plumbed to a

condensate pan located in the compressor housing.

CAUTION:

Do not overtighten drain fitting

as it may damage the threads.

NOTE: The end of the CO

2

line extends through a

sleeve on the side of the cabinet in the

machinery compartment. Connect this

line to the pressure supply with a hose

and fitting.

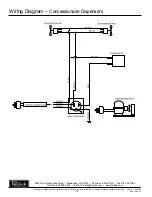

Electrical

The cabinet must be connected to a separately

fused power source (see electrical specification

plate) and grounded in accordance with National

and Local Electrical Codes. Caution: Do not

attempt to operate the equipment on any other

power source than that listed on the Electrical

Specification plate.

IMPORTANT WARNING

To avoid compressor damage.

DO NOT RUN UNIT

IF CABINET HAS BEEN

LAID ON ITS BACK

If cabinet has been laid on its back for any rea-

son, place it back into the upright position and

allow it to stand for 24 hours before running unit.