Commissioning

2

0

1

9

-0

7

17

6. If the rotary switch on the PROFIBUS side (PROFIBUS ID) is set to "7E" (= 126), the

gateway uses a PROFIBUS address that is stored in the EEPROM. This address is 126 by

default and can only be changed by a PROFIBUS master via the PROFIBUS itself. The

address 126 is reserved for this purpose in the PROFIBUS, i.e., a slave with this address

can never exchange data, but can only be configured with a new ID.

7. If the rotary switch is set to a value between 0 and 125, the gateway uses this PROFIBUS ID

and it is not possible to change the setting via a master.

4.4

Integrating the Interface Module into the Network

Installing the GSD File

A

GSD file

is required to operate the device. The GSD file can be downloaded from our

website: www.pepperl-fuchs.com. Simply enter the product name or item number in the

Product/Keyword field and click "Search." Select your product from the list of search results.

Click on the information you require in the product information list, for example, Software. A list

of all available downloads is displayed.

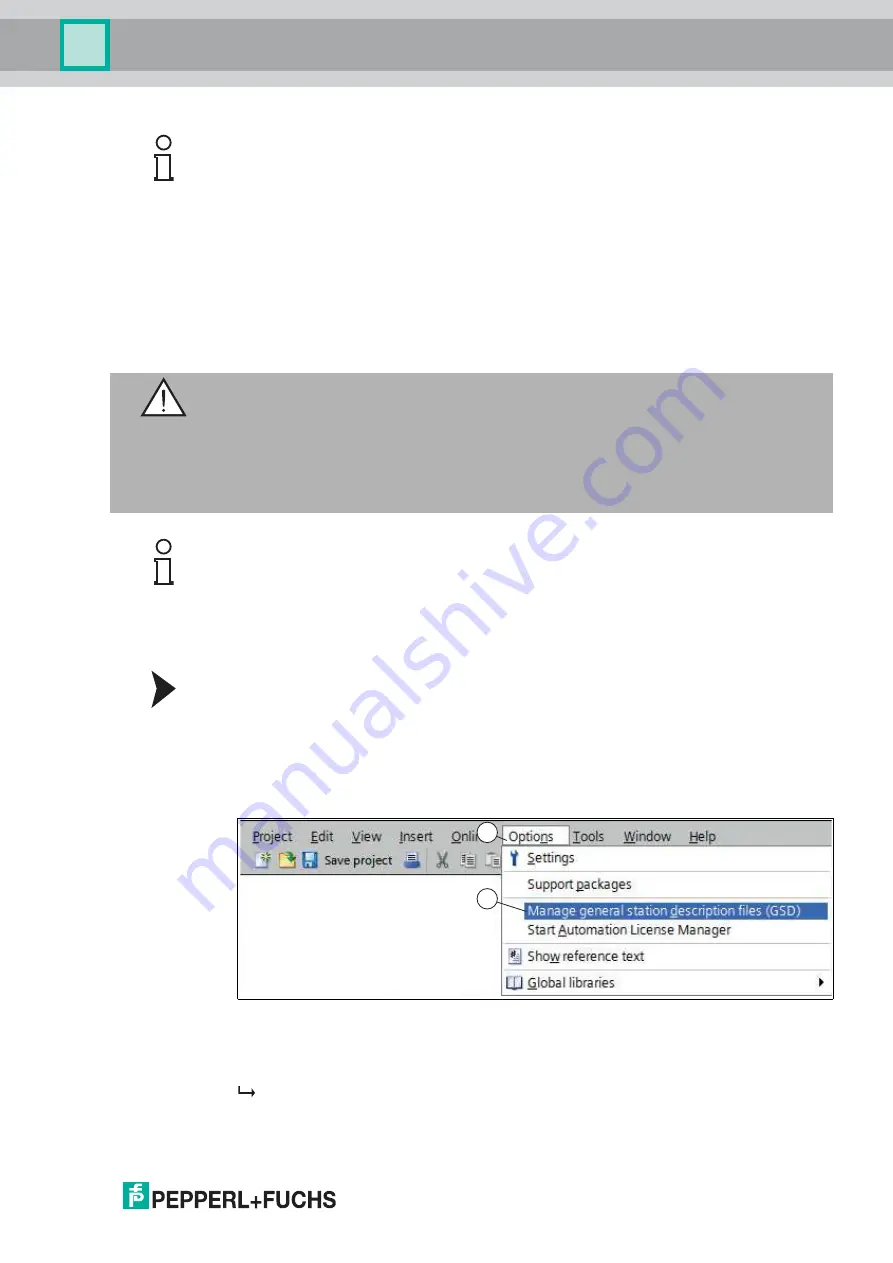

1. Start "TIA Portal V14."

Figure 4.1

GSD file

2. Under

"Options"

(1) in the menu bar, select the command

"Manage general station

description files (GSD)"

(2).

The

"Manage general station description files"

window opens.

Example!

The PROFIBUS ID is 26 decimal = 1A hexadecimal. The "PROFIBUS ID High" switch must be

set to 1 and the "PROFIBUS ID Low" switch must be set to A.

Warning!

Risk of injury due to incorrect configuration

An error during the configuration of the device can override the fail-safe function, causing a

danger to people and machinery.

■

Ensure that the device is programmed exclusively by qualified personnel.

■

Only put devices into operation after they have been configured correctly.

Note!

Various configuration tools are available to allow you to configure the interface module. As an

example, this manual describes the configuration of a Siemens control panel with the VLX-

F231-B6 interface module using the TIA Portal V14. If you are using a programmable logic

controller (PLC) from a different manufacturer, the process will be similar to the one described

here.

1

2