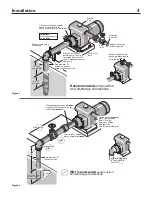

Location Of Unit

Locate the pump as near the liquid source as possible,

using a short, direct suction pipe. Keep the static suction

lift (vertical distance between the center line of the pump

and the liquid level) to a minimum. Mount the pump

on a solid, level foundation, which provides a rigid and

vibration-free support. It should be located where the

unit is readily accessible for service and maintenance.

The pump should be protected against flooding and

excessive moisture.

Piping

Both suction and discharge piping should be

independently supported at a point near the pump to

avoid strains being placed on the pump. Start all piping

at pump to avoid strains left by a gap at last connection.

Suction Piping

The suction pipe must be kept free of leaks. The suction

pipe must have a gradual slope upward to the pump.

Avoid any fittings which may cause an air trap. On units

that have a suction fitting, a check valve is a built-in

feature and no foot valve is required.

Discharge Piping

A gate valve and union should be installed in the

discharge line. For removal of the pump for service, close

the gate valve, and disconnect at union.

Electrical Information

Hazardous voltage. Disconnect power at

service panel be fore connecting motor. Single phase

motors come factory wired for 230 volt operation. Do

not alter wiring in single phase motors. Match motor

voltage to power supply voltage. Do not connect three

phase motors to single phase power supply or single

phase motors to three phase power supply.

• Ground motor before connecting to electrical

power supply.

• Failure to ground motor can cause severe or fatal

electrical shock hazard.

• Do not ground to a gas supply line.

• To avoid dangerous or fatal electrical shock,

turn OFF power to motor before working on

electrical connections.

• Supply voltage must be within ±10% of nameplate

voltage. Incorrect voltage can cause fire or seriously

damage motor and voids warranty. If in doubt

consult a licensed electrician.

• Use wire size specified in Wiring Chart. If possible,

connect pump to a separate branch circuit with no

other appliances on it.

Wiring

1. Install, ground, wire and maintain this pump in

ac cordance with your local electrical code and all

other codes and ordinances that apply. Consult your

local building inspector for local code information.

2. Ground the pump permanently using a wire of size

and type specified by local or National Electrical

Code. Do not ground to a gas supply line.

3. Connect ground wire first. Connect to ground

first, then to green grounding terminal provided

(identified as GRD or ). Make ground connection

to this terminal. Do not connect motor to electrical

power supply until unit is permanently grounded;

otherwise serious or fatal electrical shock hazard

may be caused.

4. For best ground connection, connect to a grounded

lead in the service panel or to a metal underground

water pipe or well casing at least 10 ft. long. If

plastic pipe or insulated fittings are used, run ground

wire directly to the metal well casing or use ground

electrode furnished by the power company.

Hazardous voltage. Before using pump, check

your motor nameplate for voltage. Your electric supply

voltage and the stamped nameplate voltage must agree.

Motors stamped 200 volts only or 230 volts only, must

be used with that voltage only. Motors stamped with

two voltages (for example 230/460 volts), may be used

with either supply voltage. For these motors check

connections against wiring diagram on motor nameplate

and make any changes necessary to agree with your

supply voltage. If in doubt, call a licensed electrician.

Incorrect voltage will cause serious damage to the motor.

Some models are equipped with three phase motors.

Three phase motors require magnetic starters.

To check motors for proper rotation: The shaft can be

seen through the motor - pump adapter bracket. A mark

can be made on the shaft to make it easier to notice

rotation. Jog the motor (start it briefly) and note the

rotation. It should rotate clockwise when viewed from

the motor-end. If rotation is not clockwise, see motor

nameplate for hookup information. BE SURE power is off

to the motor when working on electrical connections.

Risk of burns. Motor normally operates at

high temperature and will be too hot to touch. Before

handling pump or motor, stop motor and allow it to cool

for 20 minutes.

Installation / Electrical

5

Summary of Contents for S40093

Page 11: ...This page intentionally left blank...

Page 12: ......