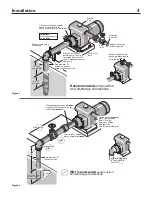

Support suction pipe

as required

Support discharge

pipe as required

As close

as possible

4 x "D"

minimum

Pipe diameter "D"

at least as large as

pump suction connection

Important:

All connections must

be

air tight

Solid, level

base

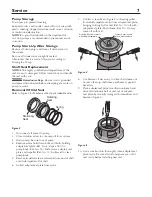

Priming

Plug

Gate

Valve

Union

Discharge

to service

Recommended pump suction

and discharge connections

Not

recommended pump suction

and discharge connections

Elbow immediately

in front of pump

suction.

High

lift

Pipe diameter "D"

insufficient size

Pipe submerged

less than 4 x "D"

will cause vortexing

Long suction

run

Valve

Unsupported

Pipe

Misaligned pipe causes

air leaks;

high spots along the suction line

result in

air pockets.

Offset suction flange adapter

keeps suction water level

above impeller eye to aid priming.

Use of excess fittings

means potential

air leaks

Straight run, short as

possible but at least 6

times pipe diameter ("D");

slope is

down going away

from pump.

1239 0894

Some models have top

discharge; these require

a priming tee.

On the discharge

avoid:

Quick closing valves.

Small I.D. pipe.

Numerous fittings.

Misalignment.

Sharp turns in piping run.

Figure 1

Figure 2

Installation 4

Summary of Contents for S40093

Page 11: ...This page intentionally left blank...

Page 12: ......