CYCLE DEFAULTS TABLE

continued

PRF40K Recharge Cycles:

Length of Cycle

Time remaining to

end of cycle

Cycle

Cycle

Description

HE

Setting

HC

Setting

HE

Setting

HC

Setting

1

Backwash 1

10 min

10 min

74 .1 min 118 .1 min

2

Brine Draw

51 min

79 min

64 .1 min 108 .1 min

Slow Rinse

3

Re-

Pressurize

3 min

3 min

13 .1 min

29 .1 min

4

Fast Rinse 1

4 min

4 min

10 .1 min

26 .1 min

5

Backwash 2

1 min

1 min

6 .1 min

22 .1 min

6

Fast Rinse 2

1 min

1 min

5 .1 min

21 .1 min

7

Refill

4 .1min

20 .1 min

4 .1 min

20 .1 min

*The camshaft does not move between Brine Draw and Slow Rinse .

Slow Rinse begins when the brine in the salt tank runs out and the

check valve closes .

PRF26K Recharge Cycle Requirements:

Minimum Salt/

Capacity

Maximum Salt/

Capacity

Salt/Recharge (lbs)

2 .6

12 .8

Regeneration Time

(min)

75

109

Water to Drain (gal)

37

44

Max . Flow to Drain

(gpm)

1 .7

1 .7

PRF34K Recharge Cycle Requirements:

Minimum Salt/

Capacity

Maximum Salt/

Capacity

Salt/Recharge (lbs)

3 .4

16 .7

Regeneration Time

(min)

76 .5

117 .5

Water to Drain (gal)

46 .3

56 .9

Max . Flow to Drain

(gpm)

2 .1

2 .1

PRF40K Recharge Cycle Requirements:

Minimum Salt/

Capacity

Maximum Salt/

Capacity

Salt/Recharge (lbs)

4 .1

20

Regeneration Time

(min)

74 .1

118 .1

Water to Drain (gal)

58 .7

72 .1

Max . Flow to Drain

(gpm)

2 .7

2 .7

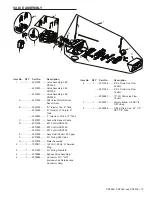

START-UP

The conditioner will now need to be placed into operation .

Please review Quick Cycling the Control procedure before

attempting start-up .

DO NOT put regenerant material into the brine tank .

1 . With the supply water for the system still turned off, position

the bypass valve to the “not in bypass” (normal operation)

position .

Both valve

handles pointing

in direction of

water flow

2 . Press and hold the button on the controller for 3

seconds . This will initiate a manual regeneration, and cycle

to the backwash position .

3 . Filling the media tank with water .

A . With the conditioner in backwash, open the water

supply valve very slowly to approximately the 1/4 open

position . Water will begin to enter the media tank . Air

will begin to be purged to drain as the media tank fills

with water .

WARNING:

If opened too rapidly or too far, media may

be lost out of the tank into the valve or the

plumbing. In the 1/4 open position, you

should hear air slowly escaping from the

valve drain line.

B . When all of the air has been purged from the media

tank (water begins to flow steadily from the drain line),

open the main supply valve all of the way . This will

purge the final air from the tank.

C . Allow water to run to drain until the water runs clear

from the drain line . This purges any debris from the

media bed .

D . Pour about 3 gallons of water into the brine tank .

Advance to cycle 2 (Brine Draw) by pressing the

and buttons at the same time . The water in the brine

tank should be drawn into the valve . If the water is not

receding from the tank, refer to Troubleshooting .

E .

Quickly cycle the control to the refill cycle (C7). Place

salt in brine tank. Allow this cycle to finish and the

control to move to service . The brine tank will have the

correct amount of water .

WARNING:

Ensure that the system has been properly

disinfected per the water conditioning

system manufacturer's recommendations.

The water conditioning system is now fully operational.

The display will show the hour of the day . The decimal point at

bottom center of the display will blink when water is flowing.

INSTALLATION CHECKLIST

___ Read the owner's/installation manual?

___ Follow all safety guidelines in the manual?

___ If metal pipe was used, did you restore the electrical ground?

___ Securely install both drain hoses to an approved drain?

___ Perform a leak test?

___ Move the bypass valve to service?

___ Sanitize the softener?

___ Add salt pellets to the salt storage tank?

___ Program the control correctly to meet your needs?

___ Start a recharge?

12 • PRF26K, PRF34K, and PRF40K