23833A245

8

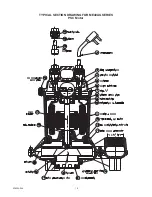

5. Lay pump on its side. Place a flat screwdriver

in the slot in the bottom of the shaft and turn the

impeller counterclockwise to remove it from the

shaft. A blow from a rubber hammer may be

necessary to loosen the impeller. Discard old seal

part.

6. Remove the four flat head screws holding the

upper half of volute to housing. Note position of

discharge in relation to switch clamp.

7. To assemble the new ceramic seal seat into your

new stator housing assembly, clean the seat cavity

thoroughly and follow Steps 7 & 8 “For Shaft Seal

Only Replacement”. NEVER USE OLD SEAL

PARTS. USE ONLY COMPLETELY NEW SEALS.

8. Assemble the upper half of the volute to housing

with the four flat head screws. Position discharge

the same as before in relation to switch clamp.

9. Make sure the shaft surface is clean and lightly

oiled. Press by hand the rotating half of the shaft

seal onto the shaft. Be sure the rotating carbon

washer is positioned adjacent to the ceramic seat.

10. Screw the impeller clockwise onto the shaft using

a screwdriver to hold the shaft from turning and

tighten impeller. Use Loctite or equal on shaft

threads.

11. Place pump upright on top of lower volute half. Be

sure mating parts are together and reassemble the

eleven machine screws and tighten.

12. Check that the impeller turns freely.

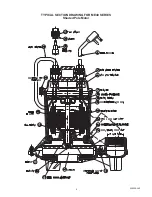

13. Guide the four motor wires up through a common

hole in the bearing plate and place the protective

plastic tube over the four motor wires.

14. Position the o-ring into cap and reconnect the four

motor wires as shown in wiring diagram. The two

green ground wires connect to the pins nearest the

‘G’ marked on the cap.

15. Put oil in the motor housing using only Myers

submersible transformer oil. The oil should be

about 1/2” above the surface of the bearing plate.

16. Reinstall the top thermoplastic cap, making sure

the o-ring is in position on the cap. Tighten the top

six screws snug, but do not overtighten.

17. Be sure the 1/8” NPT pipe plug is in the top cap.

18. Plug pump into receptacle to test operation. Pump

must run quiet and free of vibration.

NOTE: When replacing top cap with a new one, be

sure the jumper wire and pipe plug are in place. See

wiring diagram. Tether level control to motor housing

with float extended 3-5/8” to 4”.

WIRING DIAGRAM

MOTOR REISTANCE CHART

Winding

Locked

Resistance

Max.

Rotor

Model

HP Speed

V

Ph

in Ohms

Amps Amps

ME40

4/10

1550 115 1

1.2

12.0

16.0

ME40

4/10

1550 230 1

4.3

6.0

8.2

ME40AG 4/10

1650 115 1

2.0

8.0

17.6

ME40AG 4/10

1650 230 1

9.1

4.0

8.8