23833A245

11

Ref.

No.

Part

No.

Description

Req’d

Numbers

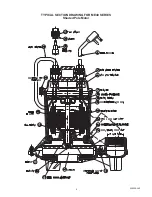

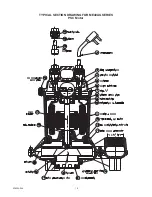

1A

Plug, nut

(manual only)

1

24448A000

1B

Washer

(manual only)

1

05030A213

1C

Plug, connector

(manual only)

1

24449A000

2

Cord, electric

1

See Chart

3

Cap, motor

(not stamped)

1

24431C000

4

Wire with terminals

1

09859A800

5

Capacitor (115 volt)

1

26446A000

5

Capacitor (230 volt)

1

23290A000

6

Cradle, capacitor (230 volt)

1

26298B000

7

O-Ring, 5-1/2 x 5-1/4 x 1/8

1

05876A146

8

Washer, spring wave

1

19331A011

9

Plate, bearing

1

24661B000

10

Oil, transformer (1 gal.)

.2 gal.

11009A008

11

Housing, with rotor & stator

1

See Chart

Stator only

1

See Chart

Rotor & shaft, ME40

1

25309A000

Rotor & shaft, ME40AG

1

26166B000

Housing only

1

27313C000

PARTS LIST ME40/ME40AG

2

11

22

Pump

Pump

Housing

Catalog

Engineering

Pump

Cord,

Cord

w/Rotor

Stator

Level

Number

Numbers

Type

Electric

Length

& Stator

Only

Control

ME40A-11

25300D000

Automatic

21628B017

10’

27313C010 21599B022 25798A550

ME40M-11

25300D001

Manual

21628B027

10’

27313C010 21599B022

---

ME40AC-11

25300D010

Automatic

21628B044

20’

27313C010 21599B022 25798A550

ME40MC-11 25300D011

Manual

21628B044

20’

27313C010 21599B022

---

ME40AC-21

25300D012

Automatic

21628B019

20’

27313C011 21599B023 25798A550

ME40MC-21 25300D013

Manual

21628B019

20’

27313C011 21599B023

---

ME40P-1

25300D900

Automatic

21628B041

10’

27313C010 21599B022 21813B130

ME40PC-1

25300D901

Automatic

21628B044

20’

27313C010 21599B022 21813B131

ME40PC-2

25300D903

Automatic

21628B019

20’

27313C011 21599B023 21813B133

ME40AG-11

27234D001

Manual

21628B044

20’

27313C012 26165B000

---

ME40AG-21

27234D002

Manual

21628B043

20’

27313C013 26165B001

---

CHART

Ref.

No.

Part

No.

Description

Req’d

Numbers

12

Seal, shaft

1

21607A015

13

Screw, machine, flat head

4

07597A030

14

Case, volute, upper half

1

25306D000

15

Screws, self tap #10 x 3/4

11

05910A012

16

Impeller

1

25301B900

16A

Sealant, Loctite 242

1

14550A001

17

Case, volute, lower half

1

25307D001

18

Gasket, Vellumoid

1

25328C000

19

Ball bearing

1

000650241

20

Screws, hex head mach.

6

18475A003

21

Suction screen

1

25307A015

22

Level control

1

See Chart