4

Hydraulic System Operation

Pump Repair Instructions

Plunger Replacement.

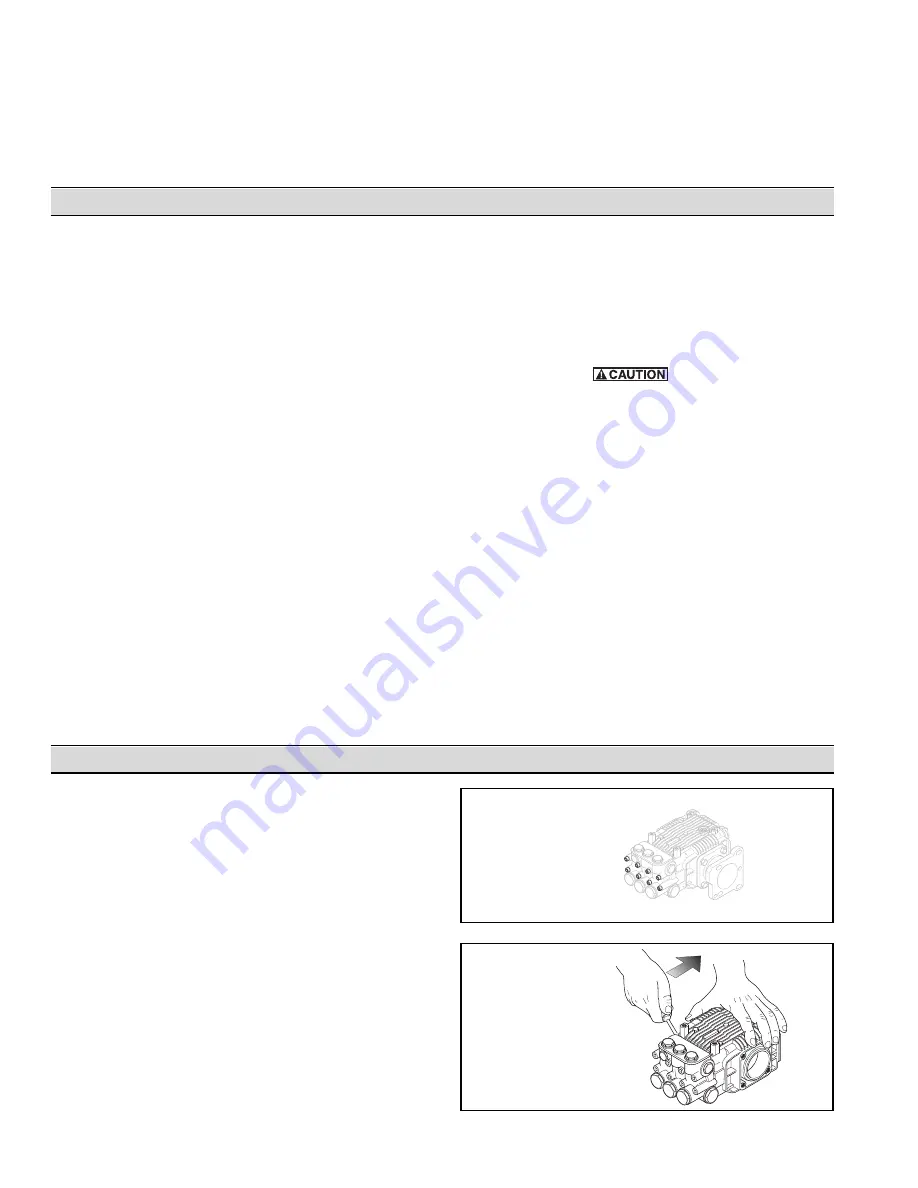

1. Using a metric allen wrench, remove the Socket

Head Cap Screws securing the Pump Head to the

Pump Body (See Figure 3).

2. While turning the Crankshaft, use two screwdrivers to

carefully pry between the Pump Head and Pump

Body to remove the Pump Head (See Figure 4).

3. Remove the plunger Retaining Nut and the Plunger

Retaining Nut Washer (See Figures 5).

4. Slide the Plungers off the Piston Guides (See

Figure 5).

5. Remove and discard the O-rings (See Figure 5).

6. Remove the Slinger Ring (See Figure 5).

Figure 3

Remove

Socket Head Cap

Screws

Figure 4

While turning the

crankshaft, use

screwdrivers to pry

the pump head off.

Hydraulic Systems

There are three types of Hydraulic Systems: Open center,

Closed Center (Pressure Compensated), and Closed

Center Load Sensing (Flow and Pressure Compensated).

Open Center Systems

In an Open Center System, the hydraulic pump puts out a

constant flow. If the Pump puts out more than the Motor

can use, a portion of the oil must be bypassed around the

Motor. The Bleeder Bypass Screw allows the fluid to

bypass around the Motor. When the oil is bypassed

around a loop and does no work, the energy put into it by

the Pump turns into heat. Therefore, this should only be

used on smaller Open Center Systems where the amount

of oil that must be bypassed is minimal.

Closed Center (Pressure Compensated) Systems

Closed Center (Pressure Compensated) Systems have a

Variable Displacement Pump that will deliver flow at the

necessary rate to maintain a specified pressure. The Flow

Control Valve should be installed at the Motor Inlet to

control the flow according to the Model requirements.

Closed Center Load Sensing Systems (Flow and

Pressure Compensating)

The Closed Center Flow Compensated System is a

variation of the Pressure Compensated System, designed

primarily for more efficient operation and the generation of

less heat. It works on the principle of maintaining a

constant pressure drop from the pump to the working port

of the Selector Valve. Any variation in demand at the

Motor will cause a change in flow. The system senses this

change in flow due to the change in pressure drop across

the Valve and causes the pump to compensate by varying

the Pump flow

Do not bypass oil. Use a Flow Control at the Motor

Inlet to control the flow and speed of the motor.

Hydraulic Oil

The specifications for the Hydraulic-Driven Pressure

Washer where compiled using Mobil DTE-26 hydraulic oil

at a temperature of 140° F [60° C]. Using other type of oil

and different temperatures will result in different flow

requirements to replicate these Pressure Washer

performance specifications. These specifications are a

guide for initial start-up.

Keep all hydraulic connections clean. The recommended

filter for the hydraulic motor is one that removes

particulates greater than and including 10 microns. The

>10 micron filter should be placed on the return line of the

hydraulic system to mitigate the risk of contaminating the

oil tank.

Change the oil after 40 hours of break-in operation.

Thereafter, change the oil every year or 500 hours,

whichever comes first.

Care of the Pump

After each use, flush the pump with a neutralizing solution

for the liquid pumped. Follow this with a clear water rinse.

For storage under freezing conditions, flush the pump with

a 50/50 solution of automotive-type antifreeze and water.

Bypass Operation

During Bypass Operation (when water is diverted back to

the pump inlet side) a temperature rise occurs. A Thermal

Relief Valve is provided to maintain the maximum water

temperature at 145° F [63° C].

Summary of Contents for HYPRO 1802C

Page 11: ...11 Mounting Dimensions Figure 17 Mounting Dimensions ...

Page 18: ...18 Notes ...

Page 19: ...19 Notes ...