1060DP SERIES

2

SECTION

2

ITEM

1060DP

DATED

NOVEMBER 2012

SUPERCEDES

MAY 2010

VESSEL DESCRIPTION:

Aurora Type 1060DP Tanks are ASME constructed, precharged

expansion tanks. They are designed to absorb the expansion

forces and control the pressure in a domestic hot water system

or a pressure booster system.

The system’s expanded water (typically from the system)

is contained behind a heavy duty – FDA approved – fixed

diaphragm preventing water contamination, tank corrosion and

waterlogging problems.

The factory set precharge for these tanks is 40 psig (276 kPa).

CONSTRUCTION DETAILS:

Materials of Construction

Shell

Steel

Liner

Polypropylene

System Connection

Stainless Steel

Fixed Diaphragm

Heavy duty Butyl – FDA approved

Maximum Operating Conditions

Working Temperature

240˚F (115˚C)

Working Pressure

125 psi (862 kPa)

STEPS & PROCEDURE:

• Visually inspect the tank for damage, which may occur

during transit.

• Factory precharge pressure may not be correct for the

installation. Tank MUST be precharged to system design fill

pressure BEFORE placing into operation. Remove pipe plug

covering the valve enclosure. Check and adjust the charge

pressure by adding or releasing air for each application.

• If the system has been filled, the tank must be isolated

from the system and the tank emptied before charging. This

ensures all fluid has exited the bladder and proper charging

will occur.

• If the precharge adjustment is necessary, oil and water free

compressed air or nitrogen gas may be used. Check the

precharge using an accurate pressure gauge at the charging

valve and adjust as required. Check air valve for leakage.

If evident, replace the Schrader-type tire valve core. Do not

depend on the valve cap to seal the leak. After making sure

air charge is correct, replace pipe plug over the charging

valve for protection.

• Set tank in place and pipe system connection to system. Be

sure to include isolation valve(s) and drain.

• Purge air from system BEFORE placing tank into operation.

All models have system water contained inside bladder.

• When filling the system with water, open valves to tank to

ensure that any residual air in the tank is displaced by water.

• It is recommended that the precharge be checked annually to

ensure proper system protection and long life for the vessel.

CALIFORNIA PROPOSITION 65 WARNING:

This product and related accessories

contain chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

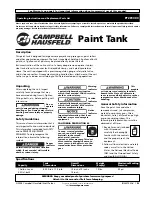

SYSTEM

CONNECTION

LIFT RING

1060DP-5 and

1060DP-12

CHARGING

VALVE

SYSTEM CONNECTION

1060DP-20 to

1060DP-210

CHARGING

VALVE