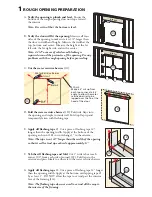

Note: When applying siding, brick veneer or other exterior finish materials, leave adequate

space between the door frame and the material for sealant. Refer to the illustration that

corresponds to your finish material. Not allowing adequate space or not using backer rod

may cause the sealant to break down prematurely and allow water to infiltrate.

7

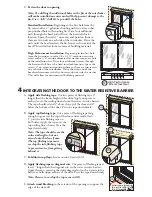

SEALING THE DOOR TO THE EXTERIOR WALL CLADDING

A.

Apply insulating foam sealant.

From the interior, insert

the nozzle of the applicator approximately 1" deep into the

space between the door and the rough opening and apply a

1" deep bead of foam. This will allow room for expansion

of the foam and will minimize squeeze out. If using foam

other than Great Stuff

™

Window and Door Insulating

Foam Sealant by the Dow Chemical Company, allow the

foam to cure completely (usually 8 to 24 hours) before

proceeding to the next step.

Note: It may be necessary to squeeze the end of the tube

with pliers to be able to insert into the space between the

door frame and the rough opening. DO NOT completely

fill the space from the back of the fin to the interior face

of the door.

Caution: Ensure use of low pressure polyurethane window and door insulating foams

and strictly follow the foam manufacturer's recommendations for application. Use of

high pressure foams or improper application of the foam may cause the door frame to

bow and hinder operation.

6

INTERIOR SEAL

*OUFSJPS

È

B.

On the interior, seal the door sill to the floor

with a corner bead of sealant.

Connect this bead of sealant to the insulating foam at both door jambs.

C.

Check door operation

by opening and closing the door.

Note: If the door does not operate correctly, check to make sure it is still plumb, level,

square and that the sides are not bowed. If adjustments are required, remove the foam

with a serrated knife. Adjust the shims, and reapply the insulating foam sealant.

Insulating

Foam

BRICK VENEER

Backer rod

and

sealant

typical

1/2" Min.

1/2"

VINYL/STEEL

SIDING

Backer rod

and

sealant

typical

1/2" Min.

1/2"

WOOD SIDING

WITH TRIM

Backer rod

and

sealant

typical

1/2" Min.

1/2"

Insulating

Foam

Insulating

Foam

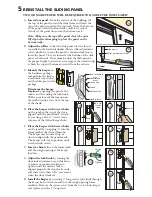

I.

Install screen

by inserting the top of the screen into the screen pocket located at the exterior

head of the patio door. Compress the top rollers just enough to allow the bottom of the

screen to be inserted onto the bottom screen track. Adjust the screen rollers by turning the

adjustment screw located at the top and bottom until the screen operates smoothly and is

plumb and centered from top to bottom. Install the screen keeper if desired.