E. Prepare The Appliance For

Installation

Open shipping carton and remove com

po nents.

Check that all installation parts are present which

includes the purification assembly, storage tank,

fau cet, installation hard ware and tubing.

Check that the air supply in the empty tank is ap -

prox i mate ly 7 psi. Adjust if necessary.

SECTION III: INSTALLATION STEPS

All plumbing should be done in accordance with

state and local plumbing codes.

NOTE: Some codes may require installation by a

licensed plumber; check with the local plumbing

au thor i ty prior to installation.

In restricted under-sink areas, it may be easier to

install the faucet first. Allow adequate tubing

lengths for any final component position.

A. Install The Faucet

See Figure 1 for Faucet Installation Diagram

The customer should be consulted before de ter min -

ing faucet location. The faucet should be po si tioned

so that it empties into the sink and the spout

swivels freely for con ve nience.

If the sink already has a hole provided that can ac -

com mo date the RO faucet, then no drilling is re

-

quired and you can proceed to the section on mount-

ing the faucet.

1. Make The Faucet Mounting Hole

IMPORTANT: It is mandatory that safety glass es

be worn during sink hole drilling operations to pre -

vent eye injury.

Before starting the hole making operation, always

check below the sink so that nothing interferes with

mount ing the faucet such as reinforcing ribs,

support brack ets or cabinet construction.

STAINLESS STEEL SINK:

Recommended tools:

• Center punch

• Variable speed drill and high speed drill bits.

• Greenlee chassis punch 7/8" hole size (alternate

9/16" size may be used for non air gap faucet)

• Protective gloves

Procedure:

a) Center punch a small indent at the desired

faucet lo ca tion.

b) Slowly drill the required pilot hole for the

chassis punch.

c) Set up the chassis punch per in struc tions and

tighten nut to cut the desired hole size.

d) Clean up sharp edges with a file if necessary.

PORCELAIN/ENAMEL/CERAMIC ON SHEET

MET AL OR CAST IRON BASE:

Recommended tools:

• Variable speed drill

• Relton porcelain cutter tool set 7/8" size (al ter -

nate 9/16: size may be used for air gap or non

air gap faucet)

• Plumber’s putty

It is important to understand what is in volved in

this procedure. First, the glassy layer of porcelain

must be penetrated through to the base metal.

Second, a center disc of porcelain must be re moved

while pro tect ing the sur round ing porcelain against

chip ping or fracturing. Third, the base metal must

be drilled through to com plete the hole.

Procedure:

a) Mark the center for the 7/8" hole

b) Form shallow putty dam around hole area

and fill with enough water to lubricate carbide

drill bit.

c) Carefully drill pilot hole through por ce -

lain/enam el and base metal using carbide type

pilot drill.

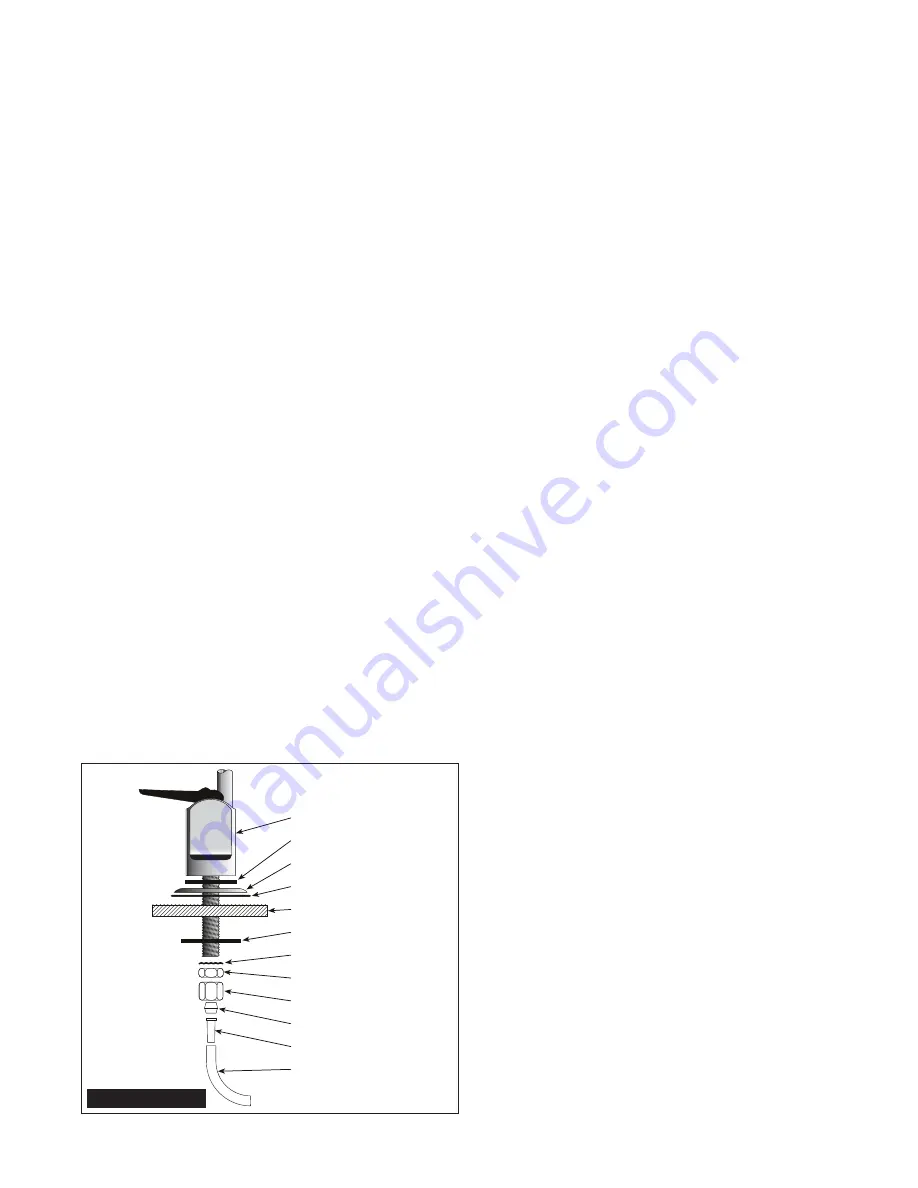

Faucet

Rubber washer

Chrome base plate

Rubber washer

Sink/countertop

Plastic washer

Star washer

Hex nut

Compression nut

Plastic ferrule

Plastic tubing insert

1/4" white tubing

FIGURE 1

Summary of Contents for OmniRO

Page 1: ...Drinking Water Systems Reverse Osmosis Installation Manual...

Page 12: ......