Pump the tyre

Check that the tyre is in good condition and make

sure that there is no damage before starting

pumping. Install the valve core if removed. Keep

your hands and body as far away from the tyre as

possible. Inflate the tyre with short inflations, while

checking the tyre pressure. Do not inflate the tyre

with lower or higher air pressure than

recommended by the tyre manufacturer.

To inflate the tyre, connect the air filler nozzle to

the tyre valve stem. Make sure that the air filler

nozzle is completely depressed over the threads of

the valve stem. When the air filler nozzle is in place,

lock it to the valve stem by releasing the locking

device. As soon as the tyre has reached the correct

tyre pressure, loosen the air filler nozzle from the

valve stem and screw on the valve cap.

WARNING! A tyre that explodes can cause

serious personal injury or even death of the

person inflating the tire. Do not underestimate

the danger.

Storage

If the tyre machine is not to be used for a long time,

it must be disconnected from the mains voltage

and the compressor. Lubricate all parts that can

rust. Drain the oil and drain the water filter. Hang

over a large plastic bag to protect from dust.

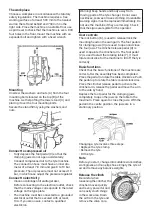

Maintenance

WARNING! Always disconnect the machine from

the electrical connection respective compressed

air connection before service or maintenance.

Pump the foot pedal several times to empty the

machine of all air. Before each use, inspect the

general condition of the machine. Check that

there are no loose screws and bolts, parts that are

incorrectly aligned, moving parts such as notches,

damaged parts, loose and damaged compressed

air hoses/electrical cables or other things that can

affect safe use. If abnormal noises or vibrations

occur, disconnect the machine from the electrical

or compressed air connection and make sure the

problem is resolved before using the machine aga

-

in. Do not use damaged equipment!

At least once a week, the table should be cleaned

with detergent or a non-flammable solvent. In

addition, the jaws and clamping jaws’ guide

grooves must be greased. Empty the water

separator (D) every day. At least once a month,

check the oil level in the pressure regulator’s mist

lubrication tank (F).

If necessary, unscrew the container and top it up

with mist oil and screw back the oil container.

Check that a small amount (a drop) of mist

lubricating oil is injected every 3-4 times the foot

pedal is depressed. If necessary, adjust the amount

of oil injected using the oil lubricator adjusting

screw (E). After a few weeks of using the machine,

retighten all bolt and screw connections, especially

those that hold the clamping jaws on the underside

of the table (B), as well as those that hold the tower

to the bottom of the machine. If the machine

seems powerless, check that the drive belt is

properly tensioned. To tighten the drive belt,

remove the sheet metal cover on the left side of the

lower part of the machine by unscrewing the two

allen screws (5 mm). Tighten the drive belt using

the adjusting screw located on the motor stand.

Summary of Contents for 32836

Page 1: ...Tyre changer U 2011 D ckmaskin U 2011 Item No 32836...

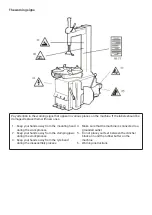

Page 8: ...Varningsskyltarna...

Page 9: ......

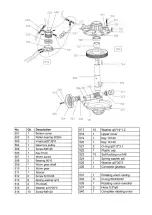

Page 16: ...Exploded view...

Page 17: ......

Page 18: ......

Page 19: ......

Page 20: ......

Page 21: ......

Page 22: ......

Page 23: ......

Page 24: ......

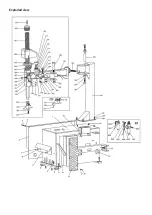

Page 25: ...Electrical circuit diagram...

Page 26: ...Pneumatic diagram...

Page 28: ......

Page 29: ......