Remove the tyre

Remove any balance weights. Brush generously

with tyre mounting paste along with the entire

tyre bead. NOTE! Failure to lubricate the tyre bead

can cause serious damage to it. Place the wheel

centred on the table. To lock the rim to the table, do

this, depending on the diameter of the rim.

Rim diameter 10”–18”

Adjust the open position on the four clamping jaws

to hold the rim from the outside by depressing the

left foot pedal. Place the wheel on the clamping

jaws, and while pushing the rim down, press the

right foot pedal. Then check that the rim is securely

locked to the table using the four clamping jaws.

Rim diameter 12”–22”

Adjust the position of the four clamping jaws so

that they are completely closed. Place the wheel

on the four clamping jaws and press the left foot

pedal so that the clamping jaws open and then lock

the rim from the inside of the rim edge. Then check

that the rim is securely locked to the table using

the four clamping jaws. Loosen the vertical arm

(M) using the lever (K) and lower it until the moun

-

ting head rests 2-3 mm from the rim and tyre side.

Then lock the vertical arm using the lever. Insert

the tyre iron between the tyre bead and the front of

the mounting head.

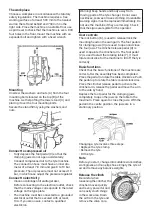

By depressing the foot

pedal (Z), the tyre bead

will be lifted above

the mounting head,

connecting the table

starting to rotate.

NOTE! To avoid damaging an inner hose (when

fitted), it is recommended to perform this step

starting from a point where the inner valve air valve

stem ends up approx. 2-3 cm to the right of the

mounting head. The tyre iron in place allows the

table to rotate clockwise by depressing the foot

pedal completely. Continue the procedure until the

tyre bead is completely removed from the rim.

Remove the inner tube (if fitted) and then repeat

the procedure of removing the tyre bead on the

other side of the tyre.

Move the tyre so that the tyre bead passes under

the front of the mounting head and lifts against the

edge of the rear of the mounting head. Using your

hands, press the tyre bead into the groove of the

rim. Then depress the foot pedal to rotate the table

clockwise. Then continue this procedure until the

tyre bead is pushed down along the entire

circumference of the tyre.

Insert the inner hose (if used). Then repeat the

procedure for the other side of the tyre/wheel.

Mount on the tyre

At the same time check

that there are no foreign

particles on the tyre

bead, in the rim or the val

-

ve. Brush generously with

tyre fitting paste along

the tyre bead to avoid damage and facilitate the

fitting of the tyre. Lock the rim using the inside of

the clamping jaws. When working with rims of the

same size, it is not always necessary to raise/lower

the mounting head between the different jobs.

Instead, leave the mounting head locked in position

and move the swingarm sideways.

Auxiliary arm function

A pneumatic auxiliary arm for the tyre changer is

indispensable when fitting/dismounting low-profile

tyres and puncture-proof tyres and at times when

it is difficult to disassemble/mount an empty tyre,

then assistance from the auxiliary arm may be

required.

Drain the air from the tyre and release the clamp.

The rim can easily be damaged by the strong

forces that arise if you use the auxiliary arm,

therefore use protection on the clamping jaws.

Depress the foot pedal so that the clamping jaws

open and then lock the rim from the inside of the

rim edge. Press down the clincher with the

auxiliary arm to facilitate lubrication with tyre

mounting paste along with the entire tyre bead.

Place the clamping jaws on the table in their

innermost position so that they do not get in the

way. Open the clincher arm by moving it to the side

with your hand. Place the tyre against the rubber

buffer (S) on the machine, then align the clincher

so that the shoulder ends up about 10 mm from

the rim edge. Press the clincher pedal (U), the

arm then presses the tyre off the rim. Repeat for

another position on the tyre until it is completely

released from the rim. Turn the tyre over and do the

same for the other side.

Summary of Contents for 32836

Page 1: ...Tyre changer U 2011 D ckmaskin U 2011 Item No 32836...

Page 8: ...Varningsskyltarna...

Page 9: ......

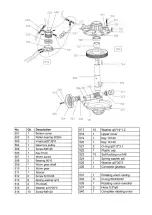

Page 16: ...Exploded view...

Page 17: ......

Page 18: ......

Page 19: ......

Page 20: ......

Page 21: ......

Page 22: ......

Page 23: ......

Page 24: ......

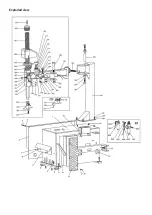

Page 25: ...Electrical circuit diagram...

Page 26: ...Pneumatic diagram...

Page 28: ......

Page 29: ......