called Sealtrode. Your installation may be furnished

with any of these according to original purchase

specifications.

FLOAT CONTROL:

The float control (when furnished)

is a type of liquid level control which provides

automatic operation of the pump unit.

On liquid level rise the float raises the float rod with

its fixed buttons until the lower button trips the float

switch, starting the pump. As the liquid level drops,

the upper float button trips the switch to the off

position, stopping the pump.

INSTALLING AND REGUATING THE STANDARD

FLOAT CONTROL:

Locate the float mechanism

where provided for on the basin cover. The usual

float switch equipment consists of a float rod, float,

guide pipe for float rod, switch stand assembly and

float rod adjusting buttons. The specific arrangement

for the C84A fixed float system or the C93A sliding

float system must be taken from the instructions

furnished with your float control.

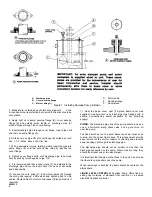

When adjusting the setting of the

low water cut-out level for any liquid

level control be sure that the liquid surface at pump

cut-out is above the top of the motor [see figure 1].

The motor is designed to operate submerged and

relies upon the liquid in which it is submerged to act

as its coolant. The temperature of the liquid being

pumped is not to exceed 105dF [40dC] to insure

proper cooling of the motor.

PUMP ALTERATION FOR DUPLEX UNITS:

When

the pumping unit consists of two pumps in a

common basin it is desirable to provide automatic

alternation of the pumps to insure equal wear and

allow

for

extra

heavy

periodic

flow

handling

capability.

Alternating control provides alternate operation of the

two pumping units on successive cycles as long as a

single pump can handle the pump load. However,

under peak flow conditions, when the liquid level

continues to rise more rapidly than can be handled

by one pump, both units are automatically placed in

operation.

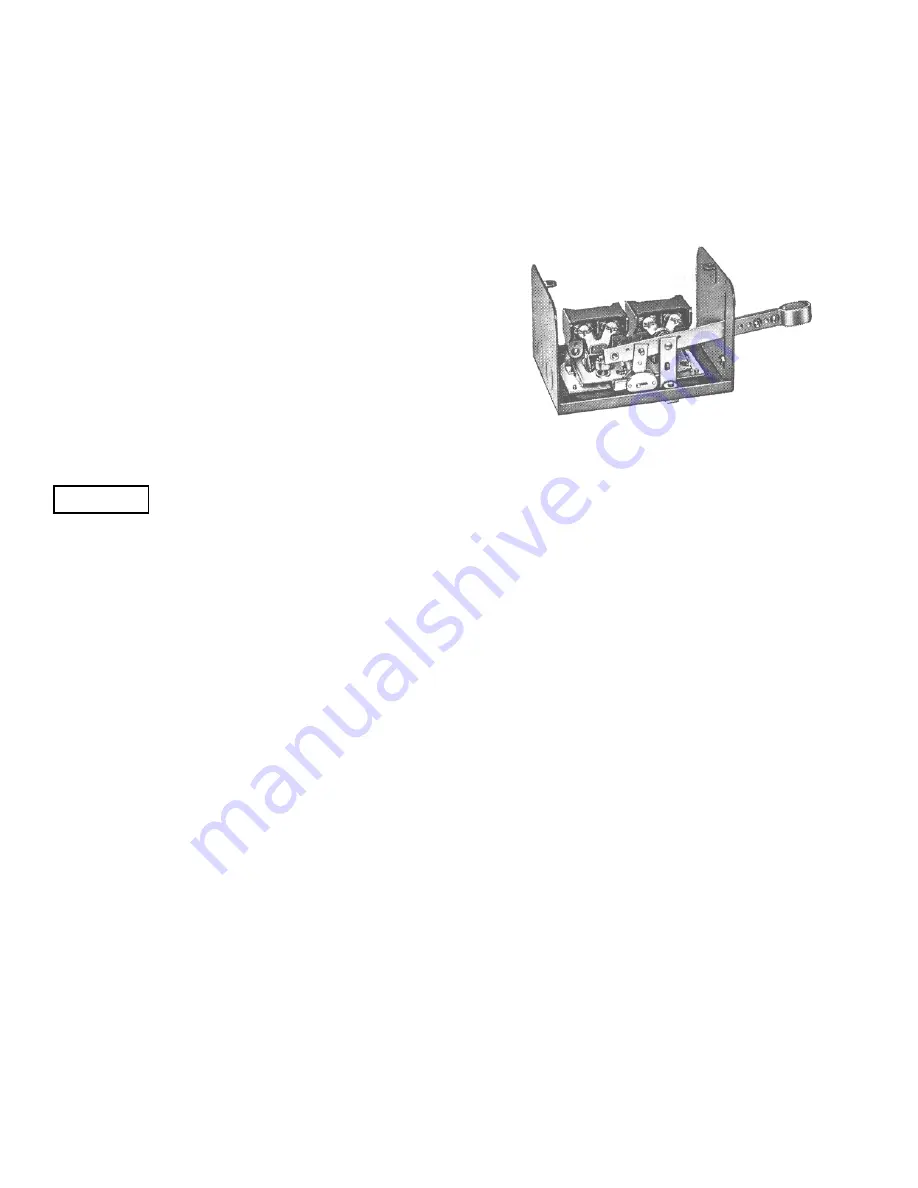

ALTERNATING TYPE FLOAT SWITCH:

The alternating

type float switch consists of two 2 pole float switches in

a single enclosure. The float switches are mechanically

connected through linkage which causes

MOTOR LUBRICATION:

No motor bearing lubrication

necessary. Motor bearings are sealed for life of unit.

alternate operation of the two pumping units. The

switch is controlled by the float which actuates the

switch on rise and fall of the liquid level. The action

is such that the two switches are alternated on

successive cycles. If the liquid level continues to rise

with one pump in operation, the switch lever arm will

continue to travel upward to a further position will

continue to travel upward to a further position at

which point the “second” switch will

operate,

starting the standby pump. The switch is illustrated

in figure 2.

Figure 2. Alternating Switch

CONTROLS:

It is recommended that a suitable

overload protector, or an across-the-line magnetic

starter be installed in the motor circuit to prevent

motor burn-outs if for some reason an overload

should occur. A float switch must not be used as the

primary starting device in 3-phase installations. It is

always used to pilot a magnetic starter. Some

1-phase installations also must employ the float

switch as a pilot device only. Check the horsepower

and voltage limit of the switch nameplate before

wiring to decide its proper use in a 1-phase circuit.

CAUTION

FUSES:

It is recommended that Fusetron (dual

element) fuses be used if not other thermal or motor

protecting device is used. The Fusetron provides for

motor protection against burn-out. Care must be

taken in selecting the proper size Fusetron. When a

fuse blows it indicates that something is wrong,

either in the motor, pump, switch, fuse rating or

service. Do not replace a fuse until you find and

remove the cause of the blow-out.

WIRING IMPORTANT:

Connect the electric service

to the controls and make inter control electrical

connections when necessary according to wiring

instructions accompanying the switches and motor,

using conduit and wire sizes as required by local

codes. Typical wiring diagrams are illustrated in

figures 4 thru 7. Be sure the current characteristics

of voltage and frequency indicated on motor

nameplates are the same as those of the service

provided.

LUBRICATION

PUMP LUBRICATION, FLOAT ROD SEAL:

Before

starting pump and at weekly intervals thereafter,

saturate the felt washer with SAE 30 oil.

5

2899213