14

29

19

2

3

1

21

18

35

10

4

17

23

15

34

30

6

16

26

39

25

5

11

20

28

24

12

13

33

7

9

40

8

27

38

32

31

37

36

22

44

45

9

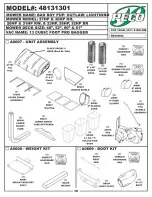

Exploded Parts View

Exploded View Of The

A0610 - PTO Assembly

Item

Number

Document

Number

Title

Quantity

1

A0593

PTO ARM ASSY.

1

2

A0429

GEAR BOX ASSEMBLY

1

3

A0436

BELT TENSION BRACKET

ASSEMBLY

1

4

B0076

BELT GUIDE BRACKET

1

5

K0348

3/8"-16 x 2" ALL THREAD

HHCS

1

6

K0047

3/8" FLAT WASHER 1.00 OD x

.446 ID x .075 T

1

7

K1193

3/8"-16 x 1-1/2" HHCS

6

8

K1215

3/8"-16 FLANGE NUT

8

9

K1197

3/8"-16 X 2 1/2" HHCS

1

10

B0075

PULLEY GUARD

1

11

K0353

1/4"-20 x 1/2" HHSTS

4

12

K1159

5/16"-18 x 2" ALL THREAD

HHCS

1

13

K1178

5/16"-18 FLANGE NUT

5

14

A0144

BLOWER MOUNT BRACKET

ASSEMBLY

1

15

B1755

BLOWER PIVOT ROD

1

Item

Number

Document

Number

Title

Quantity

16

K0086

.125 OD x 2.50 HAIR PIN CLIP

2

17

B0121

BLOWER BELT GUARD

1

18

A0604

PTO HANDLE MOUNT ASSY

1

19

A0422

CAM BRACKET ASSEMBLY

1

20

K0356

3/8"-16 TAPERED SET

SCREW

1

21

A0603

PTO HANDLE ASSEMBLY

1

22

V1151

5/8" ID x 4-3/4" BLACK

HANDLE GRIP

1

23

B0162

SKID PLATE

1

24

K1142

5/16"-18 x 3/4" CARRIAGE

BOLT

4

25

K0326

BELT TENSION ROD 3/8"-16

1

26

K0130

.091 OD x 1.625 L HAIR PIN

CLIP

1

27

K1222

1/4"-20 X 3/4" HHCS

3

28

K1128

1/4"-20 NYLOC NUT

3

29

A0306

PTO SHAFT ASSEMBLY

1

30

J0254

3/16" SQ. x 3/4" LONG

KEYWAY

1

Item

Number

Document

Number

Title

Quantity

31

M0228

BLOWER PULLEY

1

32

K1446

1.187 OD x .380 ID x .187

WASHER

1

33

K1190

3/8"-16 x 3/4" HHCS

1

34

E4004A

BLOWER HSG. ASSY.

1

35

A0645

SMALL 4-BLADE IMPELLER

1

36

S4302

TAPER-LOCK BUSHING

1

37

S3242

PLATED BUSHING

1

38

K1225

1/4"-20 X 1" HHCS GRADE 8

2

39

K0278

TAPER-LOCK BUSHING

WASHER

1

40

K1211

3/8"-16 x 1-1/2" HHCS GRADE

8

1

41*

E6009

8" BLOWER CONE

1

42*

K0125

5/16"-18 x 2-1/2" ALL THREAD

HHCS

2

43*

K0120

5/16"-18 JAM NUT

2

44

M0237

A33K

1

45

M0247

A53K

1

KEVLAR BELT

FOR 31HP

KAWASAKI

A52K

M0238

FOR ALL

OTHER ENGINES

/ M0238