FW6 Building Instruction February 2015

www.pcm.at

14

If you want to make the most beautiful solution, you can lead

the wire out of the pylon and place the lever right behind. But

you have to shorten the lever a little for that.

8. Ballast:

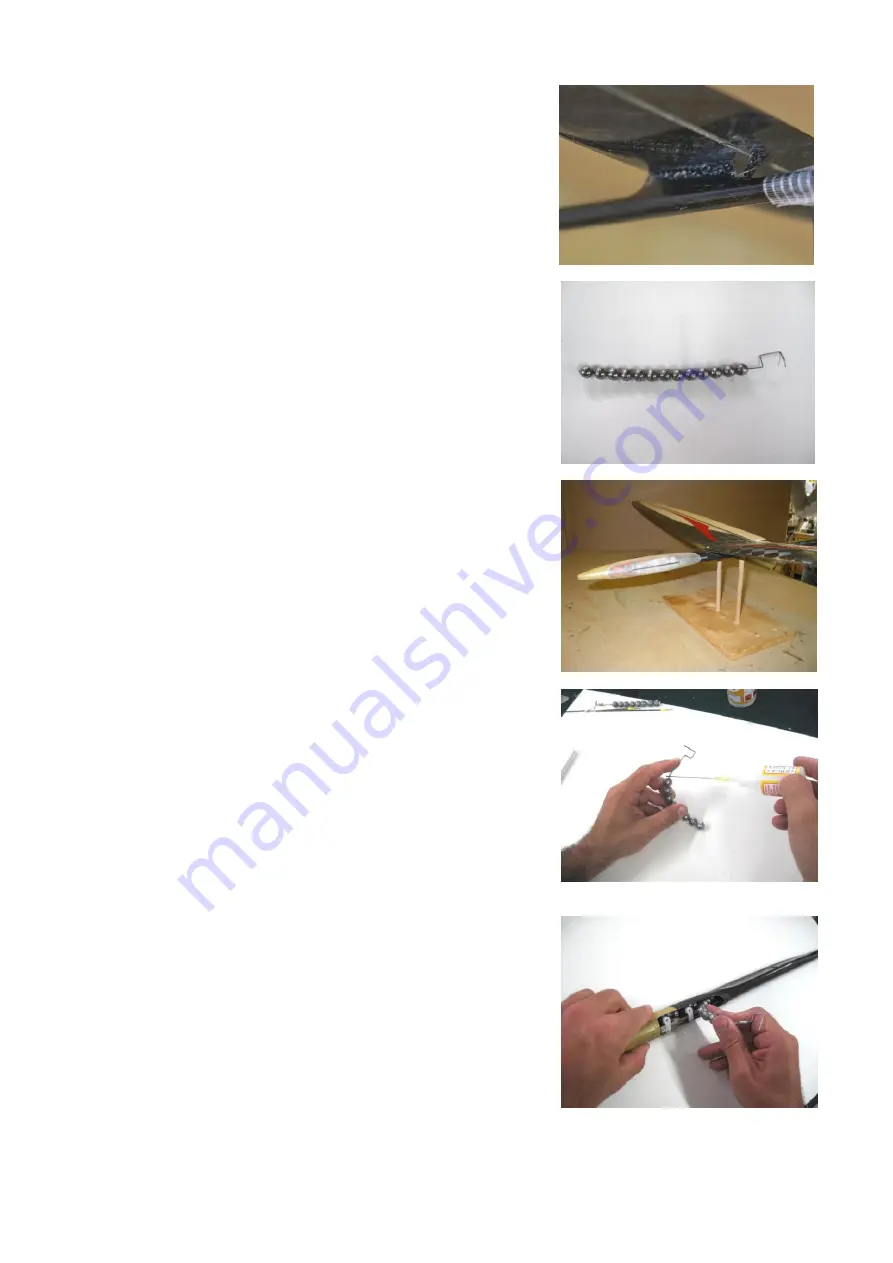

As ballast we use lead

balls

from the

fishing shop

. You can

easily assemble and vary this kind of ballast.

The balls are strung on a

steel wire of 1,0mm diameter

. Bend

the end of the wire to a small hook. With this

hook

the ballast

pack can be

locked

on the radio board.

To locate the exact position of the ballast inside the fuselage,

lay the model on a

device for measuring the centre of gravity

(see picture). Move the ballast until you get the desired centre

of gravity.

When bending the wire you should make sure that you

don’t

create 180 ° curves

, as the wire may break then.

Put a drop of thin

super glue onto

the first and the last lead

ball

to fix their position. As you must curve the ball chain for

threading it into the ballast tube, bend the wire in the desired

curvature when you glue the balls.

Insert the ballast through the left opening of the fuselage

into

the ballast tube

.

.