MANUAL: 55308

REV: A

ECO: 49582

5

For optimum performance and measurement find a

rigid location on the machine casing that most

accurately represents the vibration of the rotor,

bearing, fan, etc. to be measured.).

3.4 Mounting Sensor

When choosing a mounting method, consider closely

both the advantages and disadvantages of each technique.

Characteristics like location, ruggedness, amplitude

range, accessibility, temperature, and portability are

extremely critical. However, the most important and

often overlooked consideration is the effect the mounting

technique has on the high-frequency performance of the

accelerometer.

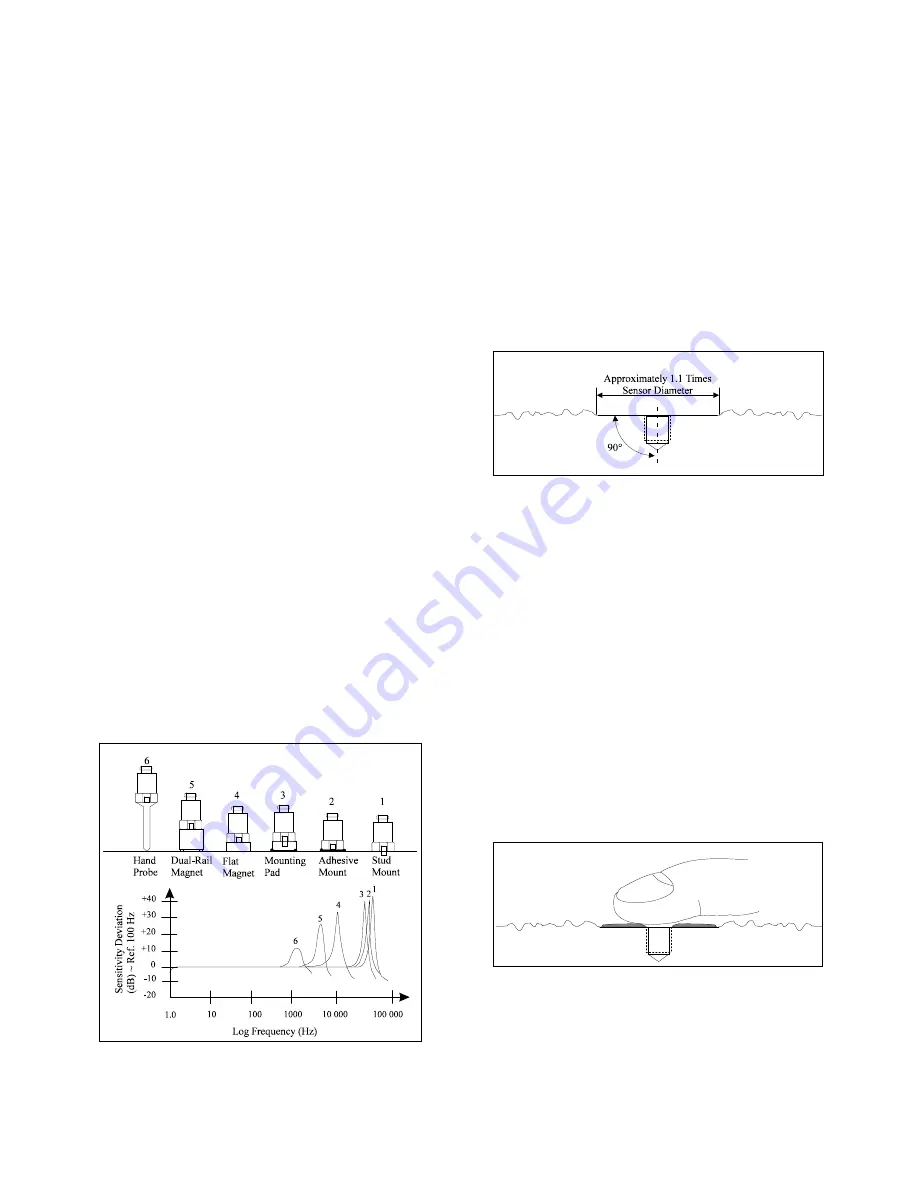

Shown hereafter are six possible mounting techniques

and their effects on the performance of a typical

piezoelectric accelerometer. (Note that not all of the

mounting methods may apply to your particular sensor.)

The mounting configurations and corresponding graph

demonstrate how the high-frequency response of the

accelerometer may be compromised as mass is added to

the system and/or the mounting stiffness is reduced.

Note:

The low-frequency response is unaffected by the

mounting technique. Its roll-off behavior is dependent

upon the coupling type or time constant of the external

charge amplifying device. This characteristic may be

fixed or adjustable, depending on the charge amplifier.

Please refer to the appropriate charge amplifier

specification sheet for information on low-frequency

characteristics.

Figure 1.

Assorted Mounting Configurations and Their

Effects on High Frequency

3.4.1 STUD MOUNT

This mounting technique requires smooth, flat contact

surfaces for proper operation and is recommended for

permanent and/or secure installations. Stud mounting is

also recommended when testing at high frequencies.

Note:

Do NOT attempt mounting on curved, rough, or

uneven surfaces, as the potential for misalignment and

limited contact surface may significantly reduce the

sensor’s upper operating frequency range.

Figure 2.

Mounting Surface Preparation

STEP 1:

First, prepare a smooth, flat mounting surface,

then drill and tap a mounting hole in the center of this

area as shown in Figure 2 and in accordance with the

Installation Drawing

for the specific sensor that is being

mounted

.

A precision-machined mounting surface with a minimum

finish of 63

in (0.00016 mm) is recommended. (If it is

not possible to properly prepare the test structure

mounting surface, consider adhesive mounting as a

possible alternative.) Inspect the area, checking that there

are no burrs or other foreign particles interfering with the

contact surface.

STEP 2:

Wipe clean the mounting surface and spread on

a light film of grease, oil, or similar coupling fluid prior

to installation.

Figure 3.

Mounting Surface Lubrication

Adding

a

coupling

fluid

improves

vibration

transmissibility by filling small voids in the mounting

surface and increasing the mounting stiffness. For semi-