Drawing Number: 21067

Revision: A

PIEZOELECTRIC CHARGE MODE PRESSURE SENSOR GENERAL OPERATION MANUAL

6

4.0

CALIBRATION

These sensors may be calibrated using static hydraulic

techniques, such as dead-weight testers, or by compar-

ison with a reference gage.

When calibrating with a laboratory-style charge

amplifier, set the charge amplifier to LONG, for the time

constant setting, and allow the sensor to stabilize before

applying pressure. If slow drift is apparent, apply the

pressure to the desired level, and immediately take a

reading. Release the pressure and take another reading

at zero pressure to obtain the difference between the

readings at the desired present level and zero pressure.

If the drift is too fast to take a reading, clean the cable

connections according to the procedures out-lined in

Section 7.0, Maintenance.

NOTE: Do not attempt to use a charge amplifier which,

in the long time constant position, has less than a 5 000-

second time constant for quasi-static calibration of

charge sensors. Any drift may cause error.

Several charge amplifiers are designed especially for use

with ceramic sensors, for higher low-frequency

measurements. In general, these types are unsuitable for

calibration of quartz pressure sensors by quasi-static

means.

A factory-supplied, NIST-traceable calibration graph is

provided with each sensor, certifying its charge

sensitivity in pC/psi, or when used with an in-line

voltage amplifier, in mV/psi.

5.0

NORMAL OPERATION

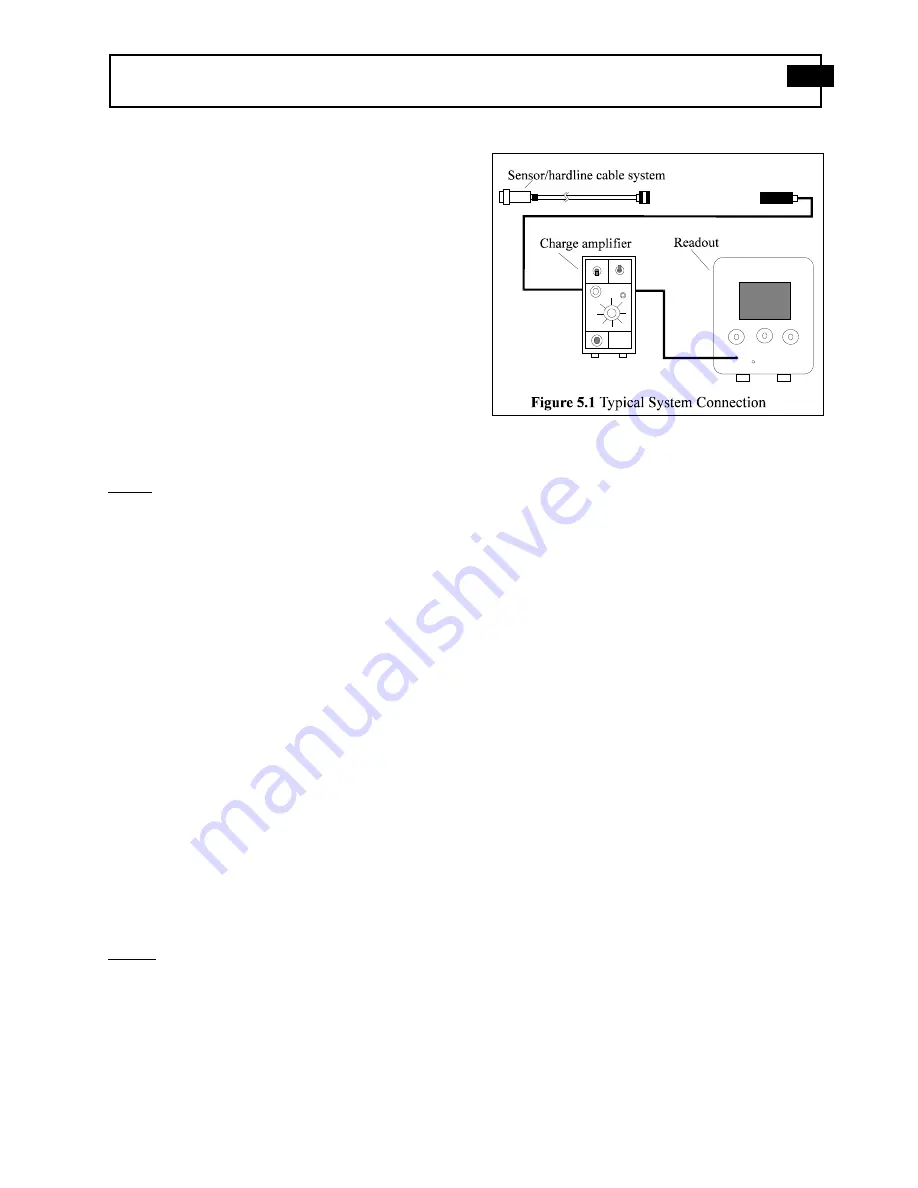

The high impedance signal generated by a charge output

sensor is usually conditioned with a laboratory-style

charge amplifier, such as the PCB Model 462A. The

charge amplifier converts the high-impedance charge

signal generated by the sensor into a low-impedance

voltage signal. This signal may then be transmitted to a

readout or recording device for analysis. See Figure 5.1

for a drawing of a typical system connection.

NOTE: When using charge-amplified systems, the noise

floor of the system is dependent on the input capacitance

to the charge amplifier. To minimize noise, keep the

cable length between the pressure sensor and the charge

amplifier to a minimum. Cable length does not affect

the system sensitivity.

Before connecting the low-noise cable from the pressure

sensor to the charge amplifier, be certain to ground the

charge amplifier. This ensures that any excessive

accumulated static charges across the sensor/cable

combination are harmlessly discharged. If this

precaution is not observed, the input FET of certain

amplifiers may be destroyed. Press the ground button of

the charge amplifier and adjust electrical zero if

necessary.

Once system components are connected, wait a few

minutes for the system to thermally stabilize. Place the

switch in the OPR (operate) position and proceed with

the measurement. Refer to the charge amplifier oper-

ating manual for further operating details.

For fixed sensitivity in-line charge amplifiers, such as

the PCB Series 422, the system sensitivity (mV/psi) is

determined as the product of the charge amplifier

sensitivity (mV/pC) and the sensor sensitivity (pC/psi).

With in-line voltage amplifiers, the system sensitivity is

a function of the sensor, cable, and the in-line voltage

amplifier.

5.1

Polarity

When subjected to increasing pressure, these pressure

sensors have a standard negative-going charge output.

Because most charge amplifiers are signal-inverting, the

resultant signal is positive-going. Reverse-polarity

sensors, for use with non-inverting source follower

amplifiers, are available upon request (“P” option).