17

11

NO PREVIOUS CODE – Stored codes

are

erased

after 72 hours

. On RED LED

boards stored status codes can also b

e

erased whene

v

er po

wer (115V or 24V

)

is interr

upted.

Run system through

a

heating or cooling cycle to

chec

k system.

12

BLO

WER ON AFTER PO

WER UP

–

(115V OR 24V) – Nor

mal operation.

Bl

ow

er r

uns f

or 90 seconds

, if unit is

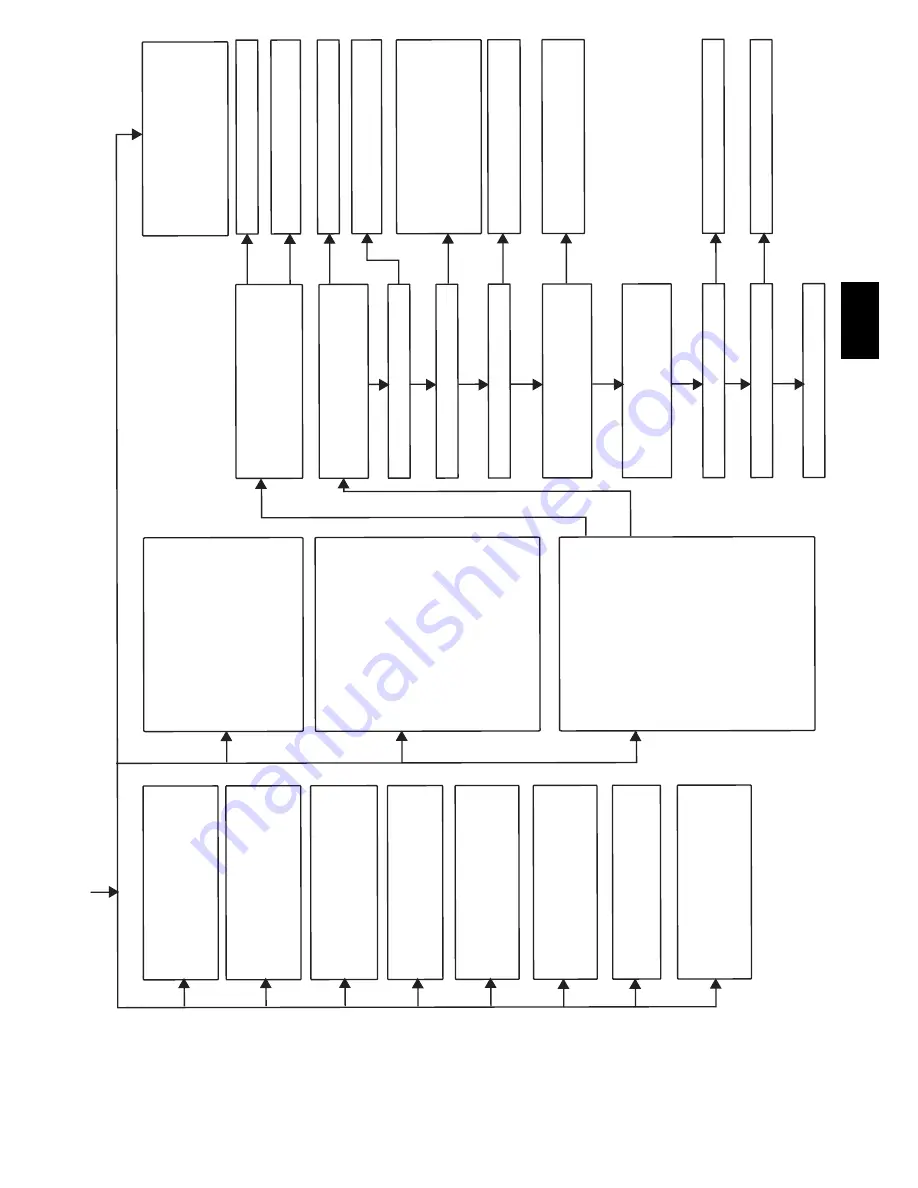

po

wered up during a call f

or heat (R-W

closed) or when (R-W o

pens) dur

ing

th

e

b

lo

w

er on-dela

y per

iod.

1

3

LIMIT CIR

CUIT LOCK

O

UT – Loc

kout

occurs if the limit or flame rollout s

w

itch is

open l

onger t

han 3 minutes

. Control wil

l

auto-r

eset after 3 hours

.

See code 33

.

1

4

IGNITION

LOCK

OUT – System f

ailed to

ignite gas

and pro

v

e

flame in 4

attempts

.

Control will auto-reset after 3 hours

.

See status code 34.

21

GAS HEA

TING LOCK

OUT –

T

u

rn off

po

wer and w

ait 5 minutes to retr

y.

Chec

k f

o

r:

-

S

tuc

k closed g

as v

a

lv

e rela

y

on cont

rol.

-

M

is

wire or shor

t to gas v

alv

e wire

.

2

2

ABNORM

AL FLAME-PR

O

VING

SIGNAL

Flame is pro

v

ed while gas v

alv

e is de-

energiz

ed.

Inducer will r

un until f

ault is

cleared.

Chec

k f

o

r:

-

S

tuc

k open or leaky gas v

a

lv

e

.

23

PRESSURE SWITCH DID NO

T OPEN

Chec

k f

o

r:

-

O

bstr

ucted pressure

tube

.

-

P

ressure s

witch stuc

k closed.

24

SECOND

AR

Y

V

O

LT

A

G

E

FUSE

IS

OPEN

Chec

k f

o

r:

-S

h

o

rt circuit in secondar

y

vo

ltage (24V)

wir

ing including ther

mostat leads

.

D

isconnect ther

mostat leads to isolate

shor

t circuit.

3

1

PRESSURE

SWITCH DID NO

T CLOSE

OR REOPENED – If open longer than

5

minute

s

, inducer shuts off f

or 15 minutes

bef

ore retr

y.

If opens dur

ing b

lo

w

er on-

dela

y

per

iod,

b

lo

w

er will come on

for th

e

selected b

lo

w

er off-dela

y.

Chec

k f

o

r:

-

P

roper v

ent sizing.

-

L

o

w

inducer v

oltage (115V).

-

L

o

w

inlet

gas pressure

(if LGPS used).

-

Inadequate comb

ustion air supply

.

-D

isconnected or obs

tr

ucted pressure

tubing.

-D

ef

ectiv

e inducer motor

.

-D

ef

ectiv

e pressure s

witch.

-

E

xcessiv

e wind.

-R

estr

icted v

ent.

33

LIMIT CIRCUIT F

AU

LT

– Indicates the

limit or flame

rollout s

witch

is

open.

Blo

w

er

will r

un f

or 4 minutes

or until open

sw

itc

h

remak

es whiche

v

er is longer

. If open

longer than 3 minut

e

s

, code changes to

loc

k

out #13.

If open less than

3 min.

status code #33 continues to flash un

til

b

lo

w

er shuts off

. Flame rollout s

witch

requires manual reset.

Chec

k f

o

r:

-

D

ir

ty filter or restr

icted duct system

.

-

Loose b

lo

w

er wheel.

-

D

ef

ectiv

e s

witch or conn

ections

.

-D

ef

ectiv

e b

lo

w

er motor or capacitor

.

-

Inadequate comb

ustion air su

pply

(flame rollout s

witch open).

-R

estr

icted v

ent.

-

P

roper v

ent sizing.

-

E

xcessiv

e wind.

- Blo

w

er motor on incorrect speed tap

.

- Input rate to fur

nace set too high.

34

IGNITI

ON PR

O

V

ING

F

AILURE

– If

flame

is not sensed dur

ing the tr

ial f

or ignition

per

iod,

the control will repe

at the ignition

sequence 3 more times bef

ore lo

ck

out

#14 occur

s

. If flame signal is lost dur

ing

the b

lo

w

er on-dela

y per

iod, b

lo

w

er wil

l

come on f

o

r the selected

b

lo

w

er off-dela

y.

Chec

k the f

ollo

w

ing items first bef

ore

proceeding to

the ne

xt step

.

-

G

as v

alv

e tur

ned off

.

-

M

anual shut-off v

alv

e

.

-G

reen/Y

ello

w

wire

MUST be connected

to fur

nace sheet metal

.

-

F

lame sensor m

ust not be grounded.

T

o

deter

mine whether the prob

lem is in

the gas v

a

lv

e

,

igniter

, or flame sensor the

system can be operated

in the component

test mode to chec

k the ignit

er

. First

remo

ve

the R ther

mostat connection from

the control and initiate the component

test sequence

. Does the igniter gl

ow

orange/white

b

y

the end of the 15 second

w

a

rm

-up per

iod?

Unplug igniter har

ness

from control and initiate

another component

test sequence

. Chec

k

for 115V between

pin 1 and

NEUTRAL-L2

on

the control.

W

as 115V present f

or the 15

second per

iod?

Reconnect the R the

rm

ostat lead and set

ther

mostat to call f

o

r heat.

Connect

v

o

ltmeter

across gas v

a

lv

e

connections

. Does gas v

a

lv

e

receiv

e 24V?

Does gas v

alv

e open and allo

w

gas to flo

w

?

Do the main b

ur

ners ignite?

Do the main b

ur

ners sta

y on?

Repeat call f

or heat and chec

k flame sensor

current dur

ing tr

ial f

or ignition per

iod.

Is the

DC microamps bel

ow

0.5?

Is current near typical v

alue?

Will main b

ur

ners ignite and sta

y on?

Fix

ed.

Clean flame

sensor with fine steel wool and

rechec

k current.

Nominal current i

s 4.0 to 6.0

microamps

.

45

CONTR

O

L CIRCUITR

Y LOCK

OUT

A

uto-reset after 1 hour lo

c

k

out due to:

-

F

lame circuit f

ailure

.

-

G

as v

alv

e rela

y stuc

k open.

-

S

oftw

are chec

k error

.

Reset po

wer to clear lo

c

k

out.

Replace

control if code re

peats

.

Replace fur

nace control

.

Chec

k

fo

r

continuity in the

har

n

ess

and

ignit

er

.

Replace def

ectiv

e component.

Chec

k connections

. If OK, replace control

.

Chec

k that all gas v

alv

es are tur

ned on.

Replace v

al

ve

.

Chec

k f

o

r:

-

Inadequate flame carr

yov

er or rough

ignition.

-

L

o

w

inlet gas pressure

.

-

P

roper fir

ing rate

.

Allo

w

b

lo

w

er to come on and repeat test to

chec

k f

or inter

mittent operation.

Chec

k connections and retr

y.

If current is

near typical

v

alue (4.0-6.0

nominal) and

b

u

rners will not sta

y on, replace

control.

Replace electrode

.

Replace fur

nace control

.

YES

YES

YES

YES

NO

YES

YES

YES

NO

YES

NO

NO

NO

YES

NO

NO

NO

NO

A05096

PG

9M

AB