GASLIGHT LOCATION, MOUNTING & ASSEMBLY

continued

LOCATION OF INDOOR GASLIGHT

Always mount gaslight on an open wall or from a ceiling with pendant kit. Never

mount gaslight in a boxed-in or recessed area.

Wall Bracket Assembly (C) must be mounted so that Heat Deflector (L) is a minimum of four

inches from a combustible surface, and outside of Globe (J) is a minimum of three inches

from a combustible surface to either side or in front. Mounting gaslights too close to a door

may subject delicate mantles to vibrations and could damage the mantle.

Assembly:

First, remove all packaging materials from gaslight.

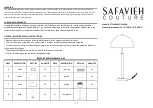

1. Remove Wall Bracket Assembly (C) and visually identify Valve Assembly (D) and Nozzle (N).

From center of Nozzle, measure a minimum of seven inches below an overhead combustible

surface, and a minimum of ten inches from a combustible surface at the front. These dimensions

will provide the minimum clearance to combustible surfaces for the Heat Deflector and Globe.

DO NOT TOUCH, DISTURB OR DAMAGE HOLE IN NOZZLE, even oil from hands can interfere

with proper gas flow.

If gas supply is to be connected through bottom of Valve Cover (G) remove Knockout tab (twist

out using pliers) in valve cover before proceeding.

2. Connect internally tinned copper tubing to Gas Inlet (B) using proper fitting (See “Fittings”

page 4). It is easier to connect the tubing before fastening Wall Bracket assembly to wall (also

Wall Bracket Assembly is less likely to be bent). Valve Assembly (D) must be straight on the Wall

Bracket. Nozzle (N) must aim into the center of the Bunsen (S) for proper air and gas mixture.

3. Fasten Wall Bracket Assembly to wall using four mounting screws (A) supplied. CAUTION: DO

NOT OVERTIGHTEN SCREWS. The four Bosses (R) on the Wall Bracket Assembly must not be

imbedded in the wall because air must circulate behind the Wall Bracket Assembly to prevent

scorching.

4. Attach Valve Cover Assembly (G) to Wall Bracket Assembly by engaging Slots (Q) with Wall

Bracket Assembly Tabs (P).

5. Carefully swing down the Valve Cover Assembly so that the slots in the bottom of the valve

cover engage Lock Screws (F). Tighten Lock Screws.

6. Check the following dimensions:

Minimum of 4 inch clearance from top of Heat Deflector (L) to ceiling.

Minimum of 3 inch clearance from outer edge to both sides and front.

Ensure 1-1/4 inch dimension between Heat Deflector and Globe Holder (M)

7. Loosen Globe Lock Screw (K), and remove Globe. Be sure that all packaging material has

been removed. Attach mantle.

8. Attach Globe after installing mantle but before burn-off (See “Mantle Installation and Lighting

Instructions”) by engaging Tabs (H) and inserting Globe so that Globe Lock Screw can be tight-

ened into the neck of the Globe. Do not overtighten.

Replacement parts and accessories are available from your local gas dealer or from

Paulin Products, Inc.

Summary of Contents for Model 9

Page 7: ......