Page 4

X

90+4°

A

Fig. 4

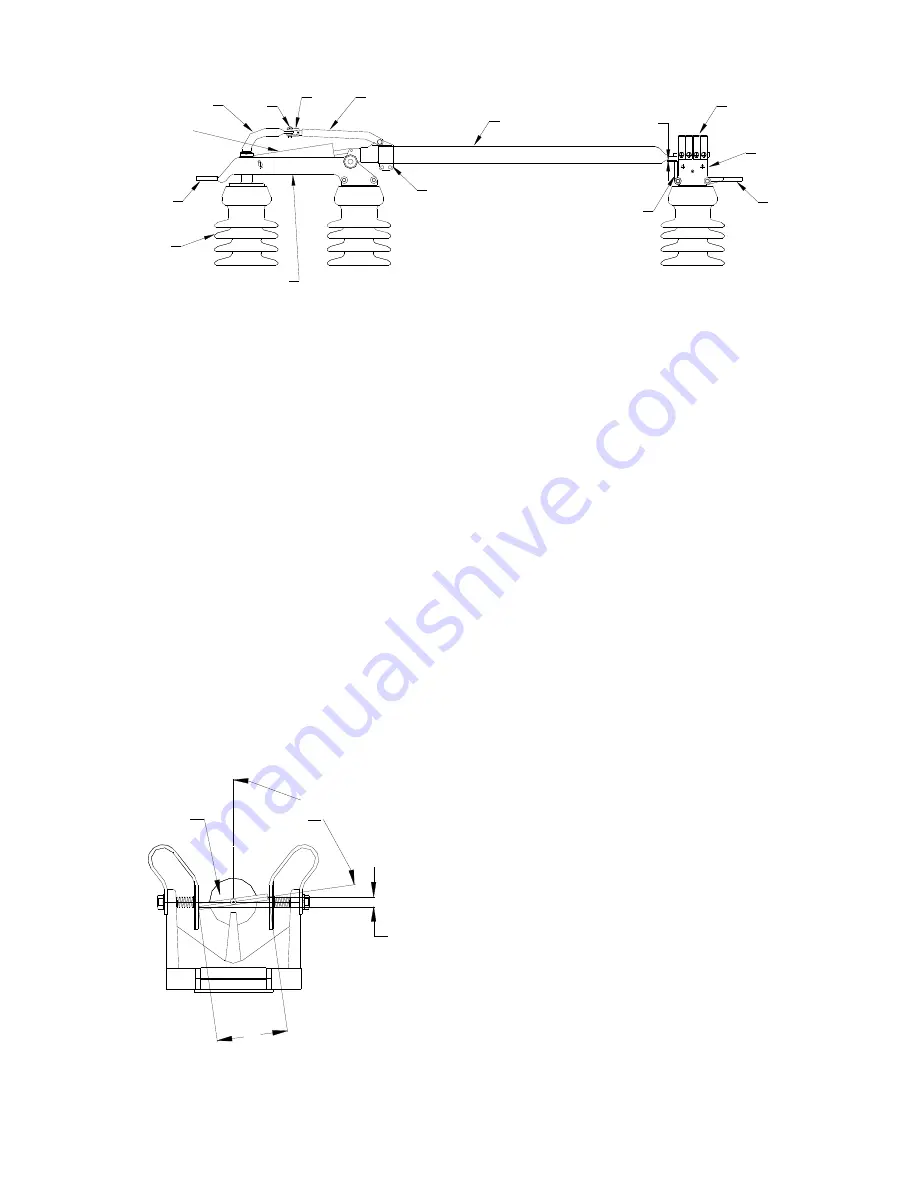

End View Showing Blade Contact Angle

Blade Contact

End

Dimension D

A

B

Terminal

Pad

Rotating

Insulator

Blade

Fork Link

Blade Clamp

Tie Casting

Counterbalance

Terminal

Pad

Contact

Fingers

Jaw Casting

Blade Stop

Gooseneck Crank

Fig. 3 Typical Set of Current Carrying Parts

Important: If it is expected that the conductors to

be attached to the switch jaw will impose an

appreciable horizontal force, it is recommended

that the jaw insulator column be adjusted so that

the jaw fingers are slightly off center on the blade

contact, in a direction toward the hinge end.

Blade Contact Angle

—(Fig. 4) The allowable

difference in elevation from one side of the blade

contact to the other (dimension X) is 1/16” for

each 1” of contact width. Example: If contact

width (A) is 4 1/2”, then dimension (X) can be as

much as 9/32” and still be within the plus or minus

4 degree tolerance.

Also, Fig. 4 shows blade contact high on the right

and low on the left. The reverse is also acceptable,

high on the left and low on the right. It is common

to have both situations on one three-pole switch.

In fact, after all three poles have been adjusted in

the open position, and then closed, you may find

that one pole will be high on the right, one fairly

level and one high on the left. This is

due to many variables and tolerances plus the free

play or clearance in pin connections of all the

switches and control parts.

With the switch blade in the closed position, the

gooseneck crank arm and fork link will over-toggle

to the left of the switch center line when looking

from hinge to jaw end of the switch phase.

Note: switch blade angle in the blade clamp is set in

the factory. This is not an adjustment point for

blade contact angle.

Blade Height in Jaw

—In Fig. 3, dimension (D) can

vary from 0” to 5/8” with the switch in the closed

position. It is not usually possible to get this

dimension to be equal on all three poles of a three-

pole switch. If it’s necessary to adjust this

dimension, remove connecting pin (A) and turn

clevis (B) in or out ½ turn then reconnect and try

switch. Turning the clevis in will move the blade

away from the blade stop. Conversely, turning the

clevis out will move the blade closer to the blade

stop.

Note: clevis assembly is a left hand thread

connection!

Step 7—Mount Offset Bearing

For those installations requiring an offset bearing,

mount the offset bearing and its supporting base on

the structure in the position shown on the

installation drawing. Fig. 5 shows a typical

arrangement using the offset bearing. Check

operating crank for proper length radius and angle,

and stop crank for correct position. These are

defined in the notes on the installation drawing.