Plunger Cart

Experiments

22

012-14781A

If the acceleration is uniform, Eqn. 2 equals Eqn. 3. You can use the measured values of the angle

ø (the angle of uniform acceleration), the distance d, and the time t to calculate the kinetic coefficient

of friction µ

k

.

Procedure

NOTE: To get consistent results in this experiment, you must insure that the ramp you will be using

is both straight and clean. Wipe the surface of the ramp and the friction block with a rag.

Determining the coefficient of kinetic or "sliding" friction:

1. Place the cart with the friction block on the ramp. Set up the ramp at a relatively low angle (one that

does not cause the friction block to begin sliding down the ramp by itself).

2. Increase the angle of the ramp until the block begins to slide down the ramp on its own, but only

after you “release” it by slapping the table (or tapping the ramp very lightly). Now increase the angle

of the ramp by a few more degrees, so that the block will slide down the ramp with a uniform

acceleration when you release it with a “slap” or tap. The angle of the ramp must be low enough

so that the block does not begin to slide on its own only when you release it. Measure the angle of

the ramp with the protractor and record it as the angle of uniform acceleration (ø) in the data table.

3. Release the block from the grasp of static

friction as described in the previous step and

measure the time of the cart’s descent down

the ramp. Record this time as t in data Table

6.1. Measure the distance d that the block

slides down the ramp and record this data in

Table 6.1. Repeat the measurements four

times. Use Eqn. 3 to compute the accelerations

of the block and enter the values in data Table

6.1. Determine the average value of accelera

-

tion and enter it below data Table 6.1.

4. Use Eqn. 2 to calculate the coefficient of kinetic or “sliding” friction. Enter it below the data table.

Prediction of D and Measurement of D:

5. Now slightly reduce the angle of the ramp until the block will just barely slide down the ramp with a

uniform speed when you release it with a slap or tap. Measure this “slip” angle. Reduce the angle

of the ramp to about one half of the “slip” angle. Measure this new angle and record its value in

data Table 6.2 as

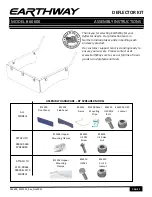

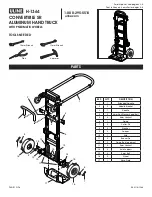

. Secure a brick or block at the upper end of the ramp as shown in Figure 6.2.

6. It is time to make a prediction – Using Eqn.1 and the information that you have recorded, predict

D, the distance that the car will slide down the ramp after being launched. Assume that the plunger

on the cart is fully cocked at the position of maximum spring compression. Record your prediction

at the top of Table 6.2.

7. After double checking your work in the previous step, launch the cart down the ramp by placing it

on the ramp with its cocked plunger against the secured brick. Then tap the Plunger Trigger with a

rod or stick using a flat edge.

NOTE: This will help to insure that you do not give the car an initial velocity other than that supplied

by the spring plunger.

8. For six trials, measure the distance D that the car slides and record these in Table 6.2.

NOTE: Sometimes the car will twist a bit as it descends, so use the midpoint of the back edge of your

car as a reference point for measuring D.

9. Compare your results with your prediction. Compute the percent difference between these two

q

Figure 6.2

Brick or Block

(about 1/2 the slip angle)