®

S tr e s s / St r a i n A p p a r a t u s

D a t a c o l l e c t i o n

6

2.

Prepare the calculation for Stress

. In the Calculator window, select the defined

function “Stress(F) = Force/Area”. In the Variables section, enter the cross-sec-

tional Area of the coupon

in square millimeters

.

3.

Prepare the calculation for Strain

. In the Calculator window, select the defined

function “Strain(F) = Displacement/Length”. In the Variables section, enter the

Length of the narrow part of the coupon

in millimeters

.

4.

Close the Calculator window

.

You now have a the characteristic baseline curve for your particular apparatus. You can save the

file and use it as the starting point for future experiments instead of repeating the calibration.

Data collection

1.

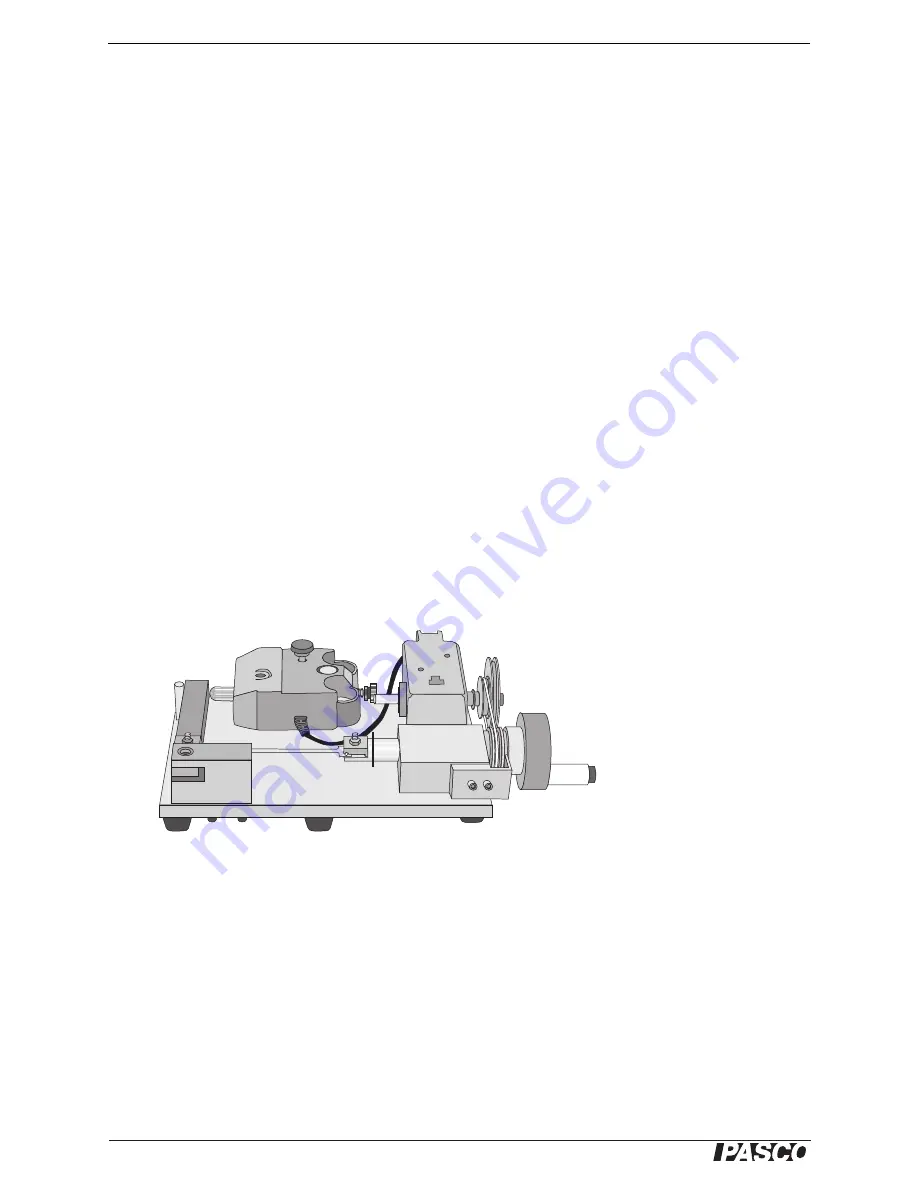

Mount a coupon

.

a.

Remove the calibration bar and restore the clips and nuts.

b.

Place one end of the coupon under one of the clips.

c.

Adjust the crank so that the opposite end of the coupon can slip easily under

the other clip (Figure 6).

d.

Tighten both nuts with the tee handle with socket. With no force applied to

the coupon, as little twist as possible should be visible in the coupon.

The

clips should hold the coupon tightly enough that it will not slip when force is

applied. However, over-tightening the nuts will damage the bolts. If in doubt,

err on the side of under-tightening

.

2.

Place the lever arm in the starting position

. Turn the crank counter-clockwise

and pull the lever arm away from the Force Sensor (Figure 4).

3.

Collect Data

.

a.

Press the Tare or Zero button on the Force Sensor.

b.

Click the Start button.

c.

Turn the crank clockwise. Starting just before the lever arm comes into

contact with the Force sensor, turn the crank very slowly.*

Figure 6: Coupon Installed

* When you observe on

the Stress versus Strain

plot that the material has

been stretched beyond

the elastic region, you

can begin to turn the

crank faster.