www.parweld.com

www.parweld.com

7

5.3 Input and grounding connection

WarnInG

Before starting the installation, check that your power supply

is adequate for the voltage, amperage, phase, and frequency

specified on the Machine nameplate.

Operate the welding power source from a single-phase 50/60 Hz,

AC power supply. The input voltage must match one of the electrical

input voltages shown on the input data label on the unit nameplate.

The input voltage is switchable between 110 or 240V ensure the

correct voltage is shown before connection the power supply. Do

not attempt to change the input voltage selector with the power on.

Refer to the specifications table for voltage tolerances.

Have a qualified electrician connect the input plug. For long runs

over 30m , larger copper wires should be used. The green/yellow

wire in the input cable connects to the frame of the machine. This

ensures proper grounding of the machine when the machine plug is

inserted into the receptacle.

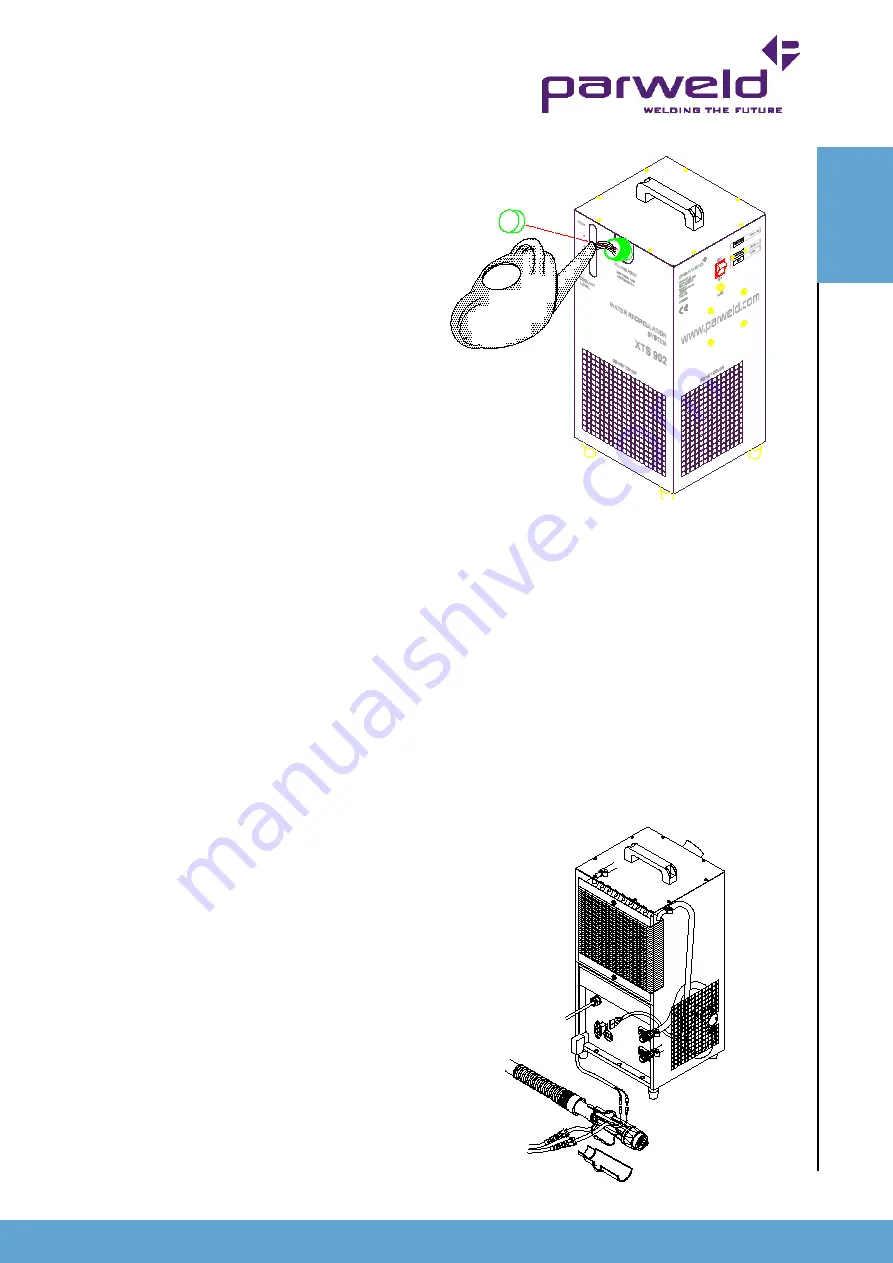

5.4 Output Connections

The Red Connection is the hot water return connection and should

be connected to the red hose on the welding torch or if connected

through the power source to the water drain connection.

The Blue Connection is the cold water supply connection and

should be connected to the blue hose on the welding torch or if

connected through the power source to the water supply connection.

Both hose connections are Type 21 Quick connections, if the water

cooler is mounted away from the power source/torch a hook up

extension kit my be used, refer to the parts list.

5.5 Coolant filing

Remove the filler cap (4) and fill the unit with Parweld UltraCool

until the Max mark is reached in the sight glass. Secure the filler

cap before starting the unit. There is not need to prime the pump

but on first running the pump should be allowed to run with the torch

connected for 1 minute to ensure all air has been expelled from the

system before welding is started. After initial running refill the water

tank to the Max level.

Warning

Operating the unit without the use of Parweld

UltraCool will shorten the life of the pump and torch. UltraCool

contains special additive to lubricate the pump and prevent corrosion

in all parts of the system including the torch.

Glycol based fluids should not be used as they

promote corrosion due to the electrical conductivity of the fluid.

6.0 Flow switch (XtS-902F)

The XTS-902F is supplied fitted with a flow switch

, this can also be purchased as a retrofit kit for the XTS-902. The

purpose of the flow switch is to prevent damage to the torch or

hoses due to a loss of water flow or failure to switch on the water

cooler. In order for the flow switch to operate correctly it must be

linked into the welding control circuit this can be done as shown

below or by wiring the control wires in series with the trigger wires

inside the power source.

Warning

Machine modifications should only be performed by competent

persons.

If the water flow falls below 1lpm then the flow switch

will operate and break the trigger circuit so stopping the welding

process. If the flow switch operates there may be an number of

causes refer to the fault finding section.

O

pera

tIO

n