www.parweld.com

8

7.0 Fault Finding

Cutting problems

Description

Possible cause

Remedy

Torch cuts but not

adequately

1. Current set too low

2. Torch is being moved

too fast across work

piece

3. Oil or moisture in

torch

1. Increase

current

setting.

2. Reduce

cutting speed

3. Ensure

water trap

on rear of

machine

is empty

(disconnect

air supply

to allow it to

drain). Put

machine

in setting

mode Hold

torch 1/8

inch (3 mm)

from clean

surface while

purging and

observe oil

or moisture

buildup (do

not activate

torch)

Heavy dross on under-

side of plate

Cutting power is to low

Increase

cutting power

6.5 Cut Quality

Cut quality requirements differ depending on

application. Bevel angle may be a major factor when the surface

will be welded after cutting. Dross-free cutting is important when

finish cut quality is desired to avoid a secondary cleaning operation.

Rounding on the top edge of a cut due to wearing from the initial

contact of the plasma arc on the work piece. Dross is molten

material which is not blown out of the cut area and re-solidifies

on the plate. Top spatter is dross which accumulates on the top

surface of the work piece. Excessive dross may require secondary

clean-up operations after cutting. Improper standoff (the distance

between the torch tip and work piece) can adversely affect tip life

as well as shield cup life. Standoff may also significantly affect the

bevel angle. Reducing standoff generally results in a squarer cut.

A guide clip and crown stand off guide is available to maintain a

constant stand off height. The plasma gas stream swirls as it leaves

the torch. The purpose of the swirl is to maintain a smooth column

of gas. The swirl effect results in one side of a cut being squarer

than the other. Viewed along the direction of travel, the right side of

the cut is squarer than the left. If dross is present on carbon steel,

it is commonly referred to as either “high speed, slow speed, or top

dross”. Dross present on top of the plate is normally caused by too

great a torch to plate distance. Top dross is normally very easy to

remove and can often be wiped off with a welding glove. Slow speed

dross is normally present on the bottom edge of the plate. It can vary

from a light to heavy bead, but does not adhere tightly to the cut

edge, and can be easily scraped off. High speed dross usually forms

a narrow bead along the bottom of the cut edge and is very difficult

to remove. When cutting troublesome steel, it is sometimes useful to

reduce the cutting speed to produce slow speed dross. Any resultant

cleanup can be accomplished by scraping, not grinding. Starting the

Cut Edge Starting For edge starts, hold the torch perpendicular to

the work piece with the front of the tip on the edge of the work piece

at the point where the cut is to start. When starting at the edge of the

plate, do not pause at the edge and force the arc to “reach” for the

edge of the metal. Establish the cutting arc as quickly as possible.

6.6 Piercing

For piercing, angle the torch slightly too direct sparks

away from the torch until the pierce is complete. Start and complete

the pierce close to the cutting line and then continue the cut onto the

line. Hold the torch perpendicular to the work piece after the pierce

is complete. Clean spatter and scale from the outer nozzle and the

tip as soon as possible. A light coating of anti-spatter compound

may be applied to the outside to minimize the amount of scale which

adheres to it. Be careful not to get anti-spatter compound on the

torch tip or other parts.

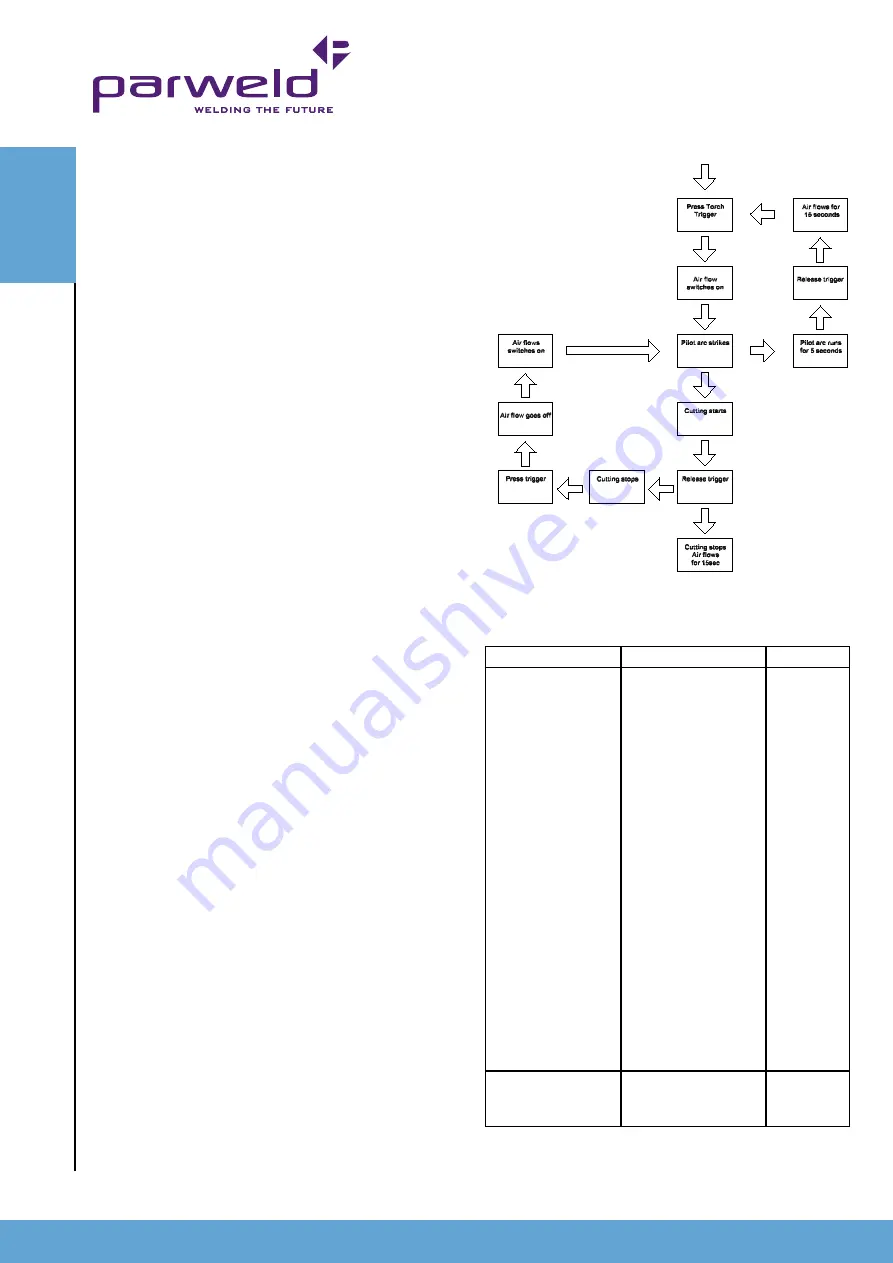

6.7 Operating the torch

With the torch in starting position press and hold the

trigger. After an initial gas purge, the main arc will come on. Once

on, the main arc remains on as long as the trigger switch is held

down, unless the torch is withdrawn from the work or torch motion

is too slow. If the cutting arc is interrupted, the cutting process must

be restarted. To shut off the torch simply release the trigger switch.

When the switch is released a 15 second post-flow will occur. If the

torch switch is closed during the post-flow, the cutting arc will restart

after switching off the air. Refer to the flow chart below for the

operating sequence.

Faul

t

FI

n

DI

n

G

Summary of Contents for XTP-63

Page 1: ...Operator Manual ISSUE 1 XTP 63...

Page 13: ...www parweld com 13...