www.parweld.com

www.parweld.com

7

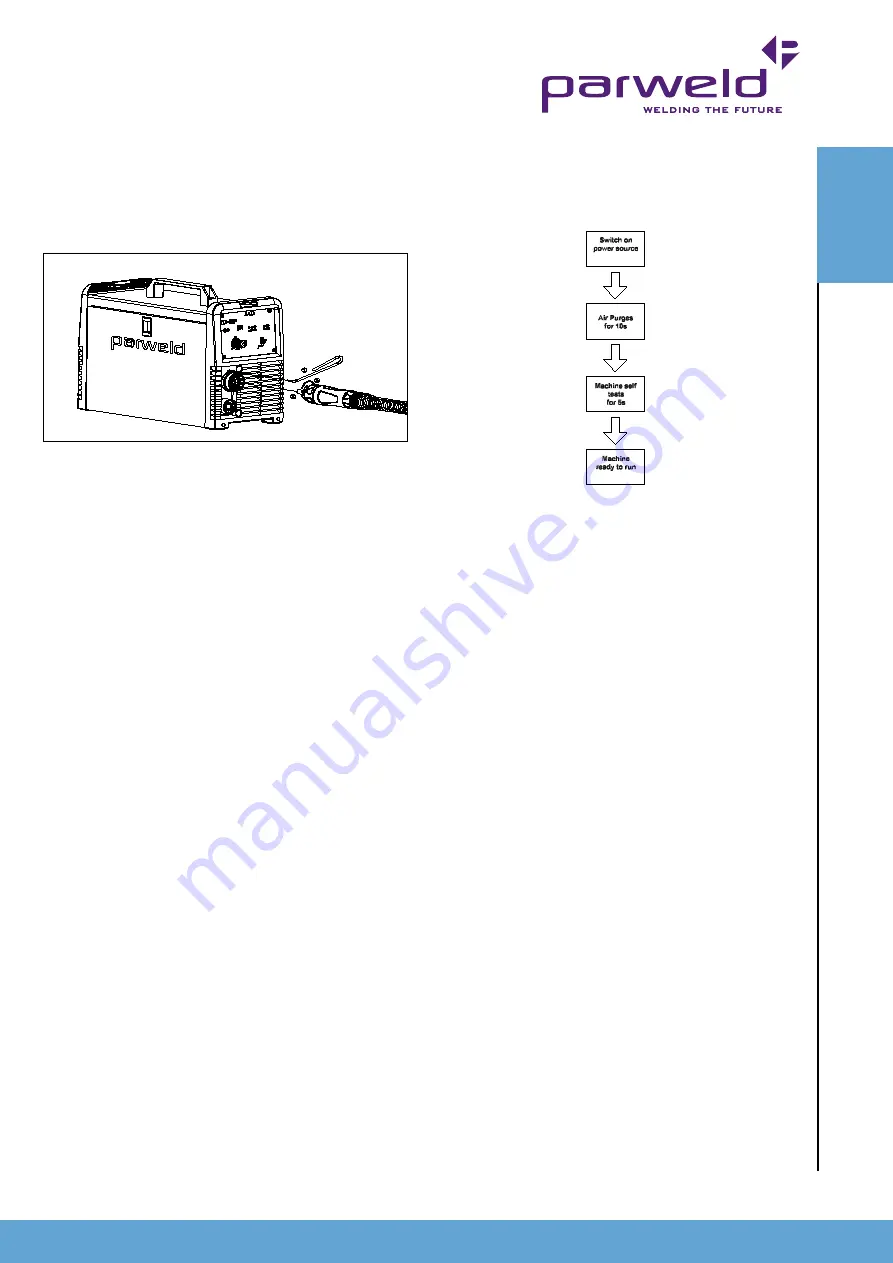

5.4 torch installation

Connect the torch to the machine using the special tool supplied as

illustrated below.

1) Insert the tool into the hole on the outside of the locking ring and

apply pressure to release the locking ring

2) Push the torch connector into the socket on the machine taking

care to line up the pins.

3) Tighten the hand nut on the torch to secure the torch

4) Release pressure on the locking tool and remove

CAUTION: Before switching on the machine ensure all spares

are fitted correctly to the torch and in good condition failure fit

spare parts can result in the destruction of the torch head.

5.6 Work return lead connection

Insert the connector in the socket and twist clockwise to lock.

6.0 Operation

WarnInG

When using an open arc process, it is necessary to use correct

eye, head, and body protection.

6.1 Consumable parts

The electrode, swirl ring and cutting tip are held in position by the

nozzle; removal of the nozzle allows these parts to be replaced.

Cutting tip size should be selected to match the selected amperage

on the machine and is not related to the thickness of the material to

be cut. Electrodes should be replaced when the insert has eroded

to a depth of no more than 1.2mm failure to replace the electrode

may result in permanent torch damage. The life of the electrode

is dependant upon the cut amperage and the number of starting

operations performed. The higher start frequency and cutting power

will give the shortest electrode life. Check the electrode condition

every 30 minutes of cutting

O

pera

tIO

n

6.2 Switching on the machine

When the machine is switched on it will perform a self

test routing as detailed following.

6.3 Setting the Air pressure

Connect the air line to the rear of the machine

and Switch on the machine. The air supply should be capable of

supplying compressed air at a pressure of 5Bar and a flow rate of

155lpm free air delivery. Switch on the machine and set the toggles

switch on the front panel to SET so that air flows through the torch.

With the air flowing ensure the interlock light does not come on, if the

interlock light illuminates then the air supply pressure to the machine

must be increased.

6.4 Getting ready to cut

Use the control knob on the front of the machine to

adjust the require output current, a higher current will give faster

cutting and a lower current slower cutting but more control for detail

cutting. The higher the set current the greater the wear rate will be

for the tip and electrode.

Summary of Contents for XTP-63

Page 1: ...Operator Manual ISSUE 1 XTP 63...

Page 13: ...www parweld com 13...