4590 Micro Reactors

P a r r I n s t r u m e n t C o m p a n y

4

PREFACE

Scope

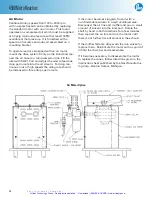

These instructions describe the installation, opera-

tion and maintenance of Parr Series 4590 Bench Top

Micro Reactors which are offered in three sizes 25,

50 and 100 mL. They cover the basic steps to be fol-

lowed when installing these reactors and describe

the function of all standard components. They are

intended to be used in conjunction with several

related instruction sheets listed below. This infor-

mation describes several components which are

common to most Parr pressure reaction equipment,

and includes safety precautions and other related in-

formation applicable to all reaction laboratories. The

users should study all of these instructions carefully

before starting to use these vessels so that they will

fully understand the capabilities and limitations of

the equipment.

Related Instructions

The following Parr publications are also included to

further your understanding of this instrument and

its component parts:

No.

Description

201M

Limited Warranty

230M

Safety Precautions to be observed when

operating Pressure Reaction Equipment

231M

Operating Instructions for Parr Safety

Rupture Discs

234M

Operating and Maintenance Instructions

for Parr Magnetic Drives

323M

Operating Instructions for Parr Pressure

Relief Valves

548M

Operating Instructions for 4848 Reactor

Controllers

FX004

Health & Safety Assurance Certification

Intended Usage

This system has been designed for use as a high

pressure reactor system. It has been designed, built,

and tested to strict physical and electrical standards.

However, it is the user’s responsibility to install and

operate it in conformance with local pressure and

electrical codes.

If this equipment is used in a manner beyond its

intended usage, the protection provided by the

equipment may be impaired.

Safety Information

To avoid electrical shock, always:

1. Use a properly grounded electrical outlet of

correct voltage and current handling capability.

2. Ensure that the equipment is connected to

electrical service according to local national

electrical codes. Failure to properly connect may

create a fire or shock hazard.

3. For continued protection against possible hazard,

replace fuses with same type and rating of fuse.

4. Disconnect from the power supply before

maintenance or servicing.

To avoid personal injury:

1. Do not use in the presence of flammable or

combustible materials; fire or explosion may

result. This device contains components which

may ignite such material.

2. Refer servicing to qualified personnel.

General Specifications

Electrical Ratings

Controller ratings are found in the Operating Instruc-

tions for the controller supplied with your reactor

and on the controller data plate.

Before connecting a controller to an electrical outlet,

the user must be certain that the electrical outlet has

an earth ground connection and that the line, load

and other characteristics of the installation do not

exceed the following limits:

Voltage:

Fluctuations in the line voltage should not

exceed 10% of the rated nominal voltage shown on

the data plate.

Frequency:

Controllers can be operated from either

a 50 or 60 Hertz power supply without affecting their

operation or calibration.

Current:

The total current drawn should not exceed

the rating shown on the data plate on the controller

by more than 10 percent.

Thermocouple:

Unless otherwise specified, all

Series 4848 Controllers operate with a Type J (iron-

constantan) thermocouple. The total resistance of

the thermocouple and the lead wires should not

exceed 100 ohms. If the resistance of the thermo-

couple circuit is higher, it will reduce the sensitivity

of the control system.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com