- 10 -

4560 Mini Bench Top Reactors

Parr Instrument Company

Revision 6-28-02

HOW TO USE THE VESSEL

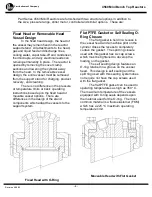

Removable Head Vessel

Flat Gasket Closure

Always remove vessels from the

support stand before attempting to open or

close them.

To Open the Vessel

Open the gas release valve to

discharge any internal pressure; then loosen

the six cap screws in the split ring sections.

Loosen the cone pointed screw in the outer

band and lower the band to rest on the

table. The ring sections can now be

removed, and the head with all attached

fittings is free to be lifted from the cylinder.

Handle the head carefully so as not to

damage the stirring shaft and other internals

when they are outside of the cylinder.

Before Closing the Vessel

Examine the head gasket carefully to

be sure that it is in good condition. After

considerable use the PTFE gaskets may

extrude a thin, ragged edge around the

inside and outside diameters. This does not

necessarily mean that the gasket must be

replaced, but the extruded portion should be

removed with a sharp knife. Examine the

mating surfaces on the cylinder and the

head to be sure they are clean and free from

burrs then set the head on the cylinder.

To Close the Vessel

Slide the two ring sections into place

and position them so that the shallow socket

drilled in the outer surface of one of the ring

sections is 180

!

from the gage face. Raise

the outer band into place around the ring

sections and position the band so that the

cone pointed screw enters the socket

described above; then tighten the screw

lightly to hold the band in place.

Fixed Head Vessels

Fixed head vessels are opened and

closed with the same procedure used for

removable vessels except that they are

opened and closed with the head in place.

Before opening the vessel lower the heater

and swing it well to the side so that it will not

be damaged by any materials that drip from

the vessel as it is opened. When closing the

vessel always hold the cylinder until both

split ring sections and the drop band are in

place to lock the cylinder to the head.

Sealing Vessels with PTFE Gaskets

Tighten each of the cap screws with

the wrench furnished with the apparatus.

Apply a firm but hard pull to each screw. If a

torque wrench is available, apply 25 ft-lbs to

each screw. Tightening should proceed in a

criss-cross pattern rather than progressively

around the circle. Let the vessel stand for

about five minutes after the initial tightening;

then tighten the cap screws again. This will

compensate for any tendency of the PTFE

gasket to flow under the loading pressure.

Routinely inspect cap screws on split

ring closure for lubrication and cleanliness.

It is important to lubricate periodically so that

the required torque is achieved when

tightening the bolts.

O-Ring Closures

The split rings used with the self

sealing O-ring do not include the six cap

screws used to seal the flat gaskets. The O-

ring is held in a groove on the underside of

the head. Before closing the vessel

examine this O-ring carefully to see that it is

in good condition. Slide the head and

cylinder together until the top of the cylinder

and the bottom of the head come together.

Now install the two split ring sections and

lock them together with the drop band.