PDEXS 125 A1

GB

│

IE

│

NI

│

7

■

Before use

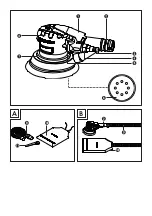

Selecting the grinding disc

Metal Removal and Surface:

The rate of metal removal and the surface quality

are determined by the grain size of the grinding

disc.

■

Lease note that corresponding grinding discs

with different grain sizes should be used for

processing different materials.

Changing sanding sheets

The air sander is fitted with a hook and loop faste-

ning, which allows for quick and easy replacement

of sanding discs.

♦

Lift the grinding disc at the side and pull it off

from the backing pad in order to remove it.

HINWEIS

►

Before securing a new sanding sheet, remove

all dust and dirt from the sander plate .

♦

Ensure that the openings in the sanding sheet

concur with the boreholes of the sanding plate .

Dust / swarf removal by suction

WARNING!

►

Please note the “Safety instructions” section.

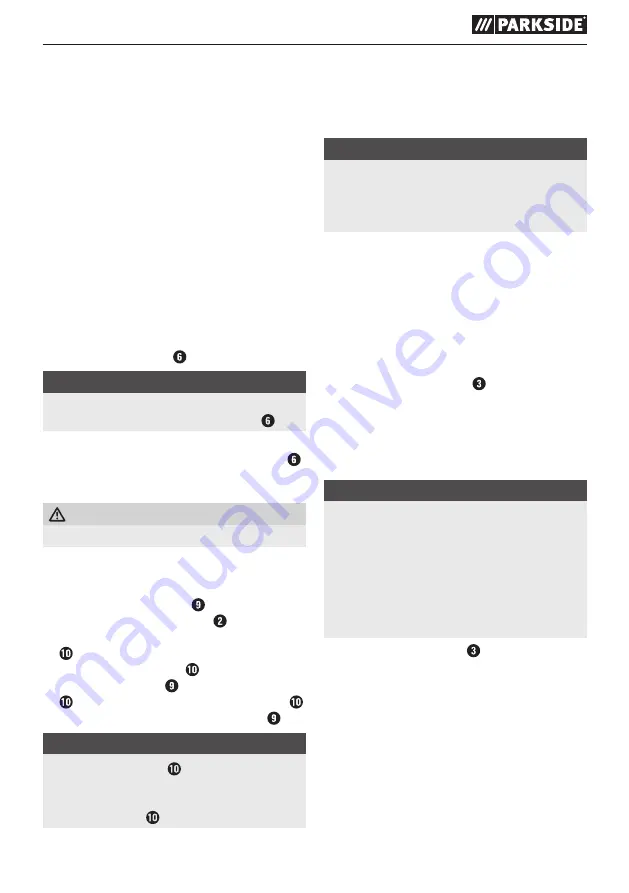

Using the internal vacuum extraction with

dust collection device (see Fig. B):

♦

Push the exhaust air hose fully on to the

connection for dust extraction .

You have to evert the opening of the dust bag

first, so that the straps are outside. Put the

opening of the dust bag over the free end of

the exhaust air hose and fasten the dust bag

firmly in position. In this way, the dust bag

can be tied tightly to the exhaust air hose .

NOTE

►

Empty the dust bag in good time and re-

gularly to ensure optimum dust extraction. To

do this open the zip fastener on the underside

of the dust bag .

Topping up the oil

In order for the air sander to have a long service

life, there must always be enough pneumatic oil in

the device.

NOTE

►

Use safe lubricants.

►

When determining which lubricants to use,

you must consider the environmental, occupa-

tional, and health aspects involved.

You may ensure this in any of the following

ways:

♦

Connect a service unit with an oiler to the

compressor.

♦

Install a line oiler in the compressed air line or

at the compressed air device.

♦

Put approx. 3–5 drops of pneumatic oil by

hand into the plug nipple every 15 minutes

of operation.

Preparing for use

Connecting the compressed air source

NOTE

►

The air sander must be operated using

cleaned and condensate-free compressed

air only and its maximum allowable working

pressure of 6.3 bar at the device must not be

exceeded.

►

The compressed air source must be fitted

with a (filter) pressure reducer so that the air

pressure can be regulated.

♦

Connect the plug nipple by a quick-release

coupler to the compressed air supply.

Summary of Contents for PDEXS 125 A1

Page 3: ...A B...

Page 15: ...PDEXS 125 A1 12 GB IE NI...