12

JINCHI05 REV E. 11/11/2014

C

OMPETENT

P

ERSONS

S

CHEME

Members of the following schemes may self-certify the installation of this stove. If the installer is not a member

of one of these schemes, your local Building Control Department must approve the installation.

Scheme

Web address

Telephone

APHC (Association of Plumbing and

Heating Contractors (Certification)

Limited

www.aphc.co.uk

0121 711 5030

Building Engineering Services

Competence Accreditation (BESCA

Limited)

www.hvca.org.uk

/

www.besca.org.uk

0800 652 5533

HETAS Ltd (Heating Equipment Testing

and Approval Scheme)

www.hetas.co.uk

01684 278170

NAPIT Registration Ltd

www.napit.org.uk

01623 811483

NICEIC Group Ltd

www.niceic.com

0870 013 0389

F

LUE

D

RAUGHT

A flue draught of minimum 1.2mm to a maximum

2.5mm water gauge is required for satisfactory

appliance performance.

The flue draught should be checked under fire at

high output with windows and doors closed. To

take the reading cover all air intakes (e.g. foil) and

put a hole through the covering where the top air

intake is for the probe to go through to take the

reading.

If it exceeds the recommended maximum, a

draught stabiliser must be fitted so that the rate of

burning can be controlled and to prevent over

firing. If the reading is less than the recommended

minimum then the performance of the appliance

will be compromised.

C

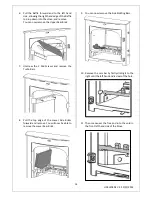

ONNECTION TO THE CHIMNEY

/

FLUE SYSTEM

The gap between the old fireplace and stove flue

outlet must be filled in so that there is a smooth

streamlined entry into the flue way. It is essential

that all connections between the stove and

chimney-flue are sealed and made airtight. Both the

chimney and any flue pipe must be accessible for

cleaning and if ANY parts of the chimney cannot be

reached through the stove (with baffle removed), a

soot door must be fitted in a suitable position to

enable this to be done.

A

IR

S

UPPLY

Where necessary, any air opening must be kept

clear of blockage or obstruction. Due consideration

should be given to air requirements for any other

appliances in the same room or space.

M

ATERIAL

C

LEARANCES

Any non-combustible walls within 50mm of this

appliance should be at least 200mm thick and

should extend 300mm above the top of the

appliance and at least 1.2 metres above the hearth.

Any walls more than 50mm from the appliance may

be reduced to a thickness of 75mm. Ensure the

inter-connecting flue pipe also has adequate

clearances to combustible materials.

A hearth with a minimum thickness of 125mm

should be provided. The hearth should extend to at

least 300mm in front of the stove and 150mm at

the sides, and should be in accordance with the

current building regulations. In all instances the

hearth and fireplace recess should be made of non-

combustible material.

The appliance shall be installed on a floor with

adequate load-bearing capacity. If the existing

construction does not meet this prerequisite,

suitable measures (e.g. load distributing plate)

should be taken to achieve it.

M

ATERIAL

C

LEARANCES

Minimum Distances to Combustible Material

Above the stove

200mm

At the side of the stove

150mm

Nearest Side Wall

310mm

In front of the stove

900mm

Note: combustible material refers to any material

that will degrade when subjected to heat (e.g.

plaster)

Summary of Contents for Chevin Inset 5 MKII

Page 24: ...24 JINCHI05 REV E 11 11 2014 ...