This equipment is part of a large range of traffic flow products. They are designed to be easy to install, as all settings and

internal wiring have been completed in our factory. Any of the instructions in this manual should only be carried out by a

qualified service engineer or a competent person.

The Gates are ready to bolt down, connect to a single phase power supply and have any pre-cut loops wired into them (Please

note that loop detectors are sold separately). The steps must be completed before the power is turned on to prevent accidents.

The following information is a guide only, and whilst we have made every effort to be accurate and correct there may be printing

errors which we cannot be held responsible for.

With a correct installation you can expect to enjoy many years of reliable service from this product, we do however recommend

that the product has a bi-annual service carried out by a qualified engineer. Please contact our service department to obtain a

quote. As we manufacture the products we are best suited to care for your equipment.

Thank you for your custom and welcome to the exciting world of Total Traffic Flow Solutions.

/

/

20

!

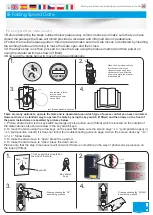

Important Safety Notice

Automatic Gates are designed to Control the flow of vehicular

traffic only. It can be dangerous to allow the passage of

pedestrians and any other self-powered animal or device to

utilise this method of access without appropriate warnings and or

signage.

It may be necessary for the end user of this product to provide

an alternative, safe method of access to cater for the previously

mentioned categories.

The end user should fit all necessary signage and warning

notices to either side of the gate, which should be visible and

clear from all directions of approach.

The product that was shipped to you was designed with a control

program to protect all categories from harm or affect this

however is only a fail safe and should not be modified or

tampered with by any unauthorised person not sanctioned by the

manufacturer.

Please sign and date below to say that you have read and

understood this notice before ANY installation work:

The “Warnings” leaflet and “Instruction booklet” supplied with this

product should be read carefully as they provide important information

about safety, installation, use and maintenance.

Scrap packing materials (plastic, cardboard, polystyrene etc) according

to the provisions set out by current standards. Keep nylon or polystyrene

bags out of children's reach.

Keep the instructions together with the technical brochure for future

reference.

This product was exclusively designed and manufactured for the use

specified in the present documentation. Any other use not specified in

this documentation could damage the product and be dangerous.

The Company declines all responsibility for any consequences resulting

from improper use of the product, or use which is different from that

expected and specified in the present documentation.

Do not install the product in explosive atmosphere.

The construction components of this product must comply with the

following European Directives: 89/336/CEE, 73/23/EEC, 98/37/EEC

and subsequent amendments. As for all non-EEC countries, the abovementioned

standards as well as the current national standards should

be respected in order to achieve a good safety level.

Information on using

this manual

Ÿ

Read all information thoroughly

Ÿ

Pay attention to all safety advice

Ÿ

Be aware of the symbols (shown above right and

above left) as they have different meanings. One is an

information symbol, the other a warning.

Ÿ

There are many artists impressions of the product in

this manual you should refer to the images as a guide

only.

Professional CAD

drawings should be used as

a reference drawing and nothing else. As before every

effort has been made to be 100% accurate in this

manual but we cannot make any guarantees.

Ÿ

As we constantly innovate our products we may

change the quoted spec and any other details that

have been documented in this manual so you should

always refer to the supplier to see if the manual that

was shipped with your product is the latest edition.

Ÿ

As with all electrical installations you should use a

qualified electrician and obey all of the latest laws and

regulations.

Ÿ

Be sure to fill out and complete

ALL

paperwork where

instructed as this manual is the equipments log book

and maintenance manual.

The Company declines all responsibility for any consequences resulting

from failure to observe Good Technical Practice when constructing

closing structures (door, gates etc.), as well as from any deformation

which might occur during use.

The installation must comply with the provisions set out by the following

European Directives: 89/336/CEE, 73/23/EEC, 98/37/EEC and

subsequent amendments.

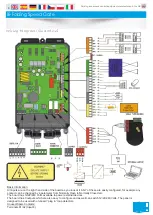

Disconnect the electrical power supply before carrying out any work on

the installation. Also disconnect any buffer batteries, if fitted.

Fit an omnipolar or magnetothermal switch on the mains power supply,

having a contact opening distance equal to or greater than 3mm.

Check that a differential switch with a 0.03A threshold is fitted just before

the power supply mains.

Check that earthing is carried out correctly: connect all metal parts for

closure (doors, gates etc.) and all system components provided with an

earth terminal.

Fit all the safety devices (photocells, electric edges etc.) which are

needed to protect the area from any danger caused by squashing,

conveying and shearing, according to and in compliance with the

applicable directives and technical standards.

in

Parking and access control equipment manufactured in the UK

Bi-Folding Speed Gate

3

Introduction and Warnings