Bulletin 100-50-5.2 –

Page 5

suction header to a maximum target value. By default, this

setpoint is high in order to provide full functional subcool

control from the factory. If the

rGhL

is set low, the control-

ler will override traditional subcool control in order to satisfy

the return gas temperature. In this state, the

LoVt

temperature

may fall below the setpoint. To access these parameters see

Section 3 - Setpoint Menu Operation,

page 4.

Manual Valve Position Feature

The Sporlan Subcool Control offers the ability to control

the subcooler expansion valve manually. This feature can be

used in troubleshooting to determine if the expansion valve

responds to an open or closed position signal directly from

the controller. In normal operation, the manual mode should

never be used.

WARNING : Be sure to avoid floodback while using

this feature. Start with the valve in the low position.

Prior to entering manual mode, attach a Sporlan Kelvin II re-

mote display to the RJ-45 port on the side of the Subcool Con-

trol to monitor superheat. This will allow the user to maintain

a minimum superheat while in manual mode by adjusting the

valve position. If the valve is positioned too far open while in

manual mode, superheat will drop and liquid may enter the

suction line. It is always better to start with the valve position

low and work up to a higher position gradually while observ-

ing the superheat value on the remote display. Superheat

should never be allowed to drop below 2°F. If this situation

occurs, reduce valve position and allow system to respond

(superheat should increase).

An alternate way to monitor superheat is to use a gauge set

and a calibrated temperature sensor on the suction line; how-

ever the pressure and temperature will need to be converted to

superheat.

To enter manual mode, press and hold the Select knob, select

111

, scroll to

Spos

and push the knob. See Section 3 - Set-

point Menu Operation

. The valve will start at the current

“original” position. The controller will show percent valve

opening. To verify if the valve is functioning, lower the valve

position by rotating the knob counter-clockwise and note

the change in superheat (increase). From this, increase valve

position slowly and note the change in superheat (decrease). It

may be necessary to allow appropriate time for system to re-

spond to changes. Ensure superheat does not drop below that

described above. To exit manual operation mode, press encod-

er knob, scroll to

ESC

, and press the knob again. After exiting

manual mode, observe the system for proper operation.

WARNING: The controller should never be left

unattended in manual mode.

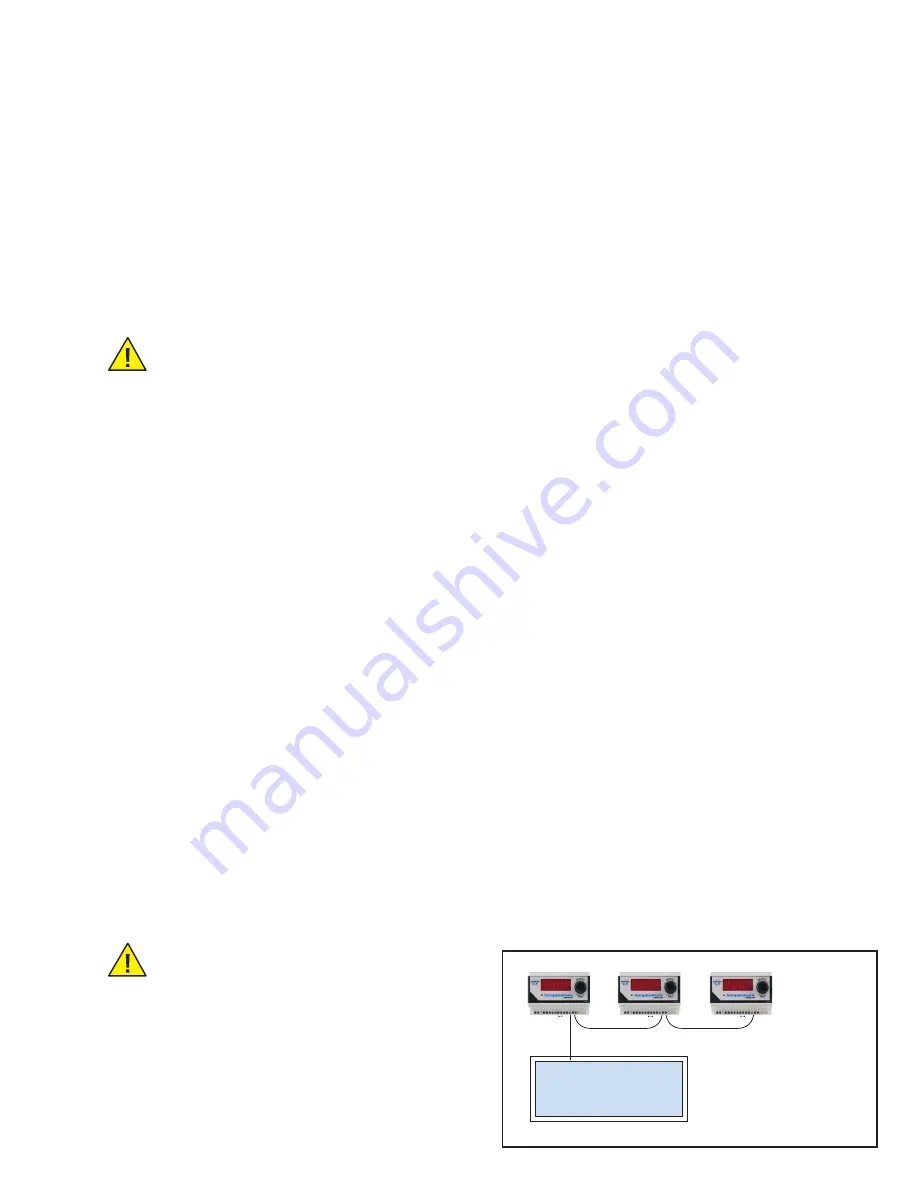

5. Controller Networking

The Sporlan Subcool Control can communicate with a

MODBUS communication master via RS485 to transfer pro-

cess values and setpoints.

The Subcool Control supports only the RTU transmission

mode. The serial settings are:

•

9600 baud (default), 19200 baud, 38400 baud

•

8 data bits

•

1 stop bit

•

Even parity (default), odd parity, no parity

The Subcool Control supports the ‘Read Input Registers’,

‘Read Holding Register’, ‘Write Single Register’, ‘Read

Multiple Coils’ and ‘Write Single Coil’ function codes. Other

requests will cause an exception response. The Subcool

Control will allow a full and partial block read of the Input

and Holding registers and coils.

Scaling for Celsius / Bar

For better precision, scaling is used for Bar or Celsius units.

PSI and Fahrenheit values are whole numbers and have no

scaling. See Appendix K - MODBUS Memory Map.

Celsius values transferred via MODBUS are 10X. For exam-

ple A value of 45 will be transferred for the Superheat when

the actual Superheat temperature is 4.5°C. Remember this

when changing a setpoint.

Bar values transferred via MODBUS are 100X. A value of 34

will be transferred for the Pressure Sensor Calib. Offset when

the actual pressure is .34 bar. Remember this when changing

a setpoint.

Setup

The Sporlan Subcool Control can be networked to com-

municate process variables back to a master controller. This

information can be used for verifying system performance or

updating individual setpoints via RS-485 and PC interface.

Data can be accessed remotely through the master controller.

For further information on remote monitoring of subcooling,

see corresponding manuals for the master controller.

Prior to establishing the network, each controller must be

assigned a separate address. Refer to Section 3 – Setpoint

Menu Operation

to enter setpoint menu. Once in the Setpoint

menu, scroll to

AddR

and set each controller on the network

with individual addresses. Note: No two controllers can have

the same address. Default address for each controller is ‘1’.

MODBUS Communication Requirements

See Figure 4 - MODBUS Wiring.

Wire Type:

22-24 AWG Universal Twisted Pair

Maximum Number of Network Nodes:

100

Maximum Run Length:

4000 ft

Communication

Master

Figure 3 - Daisy Chain

Network Configuration