Bulletin 100-50-2.1 –

Page 3

1. Installation

TOOLS REQUIRED:

• Small flat screwdriver for terminal connections

• Phillips and flat screwdrivers

• Cordless screwdriver

• Needle-nose pliers

• Wire cutters

• Two #8 x ½” self-tapping screws to mount SNAP Track

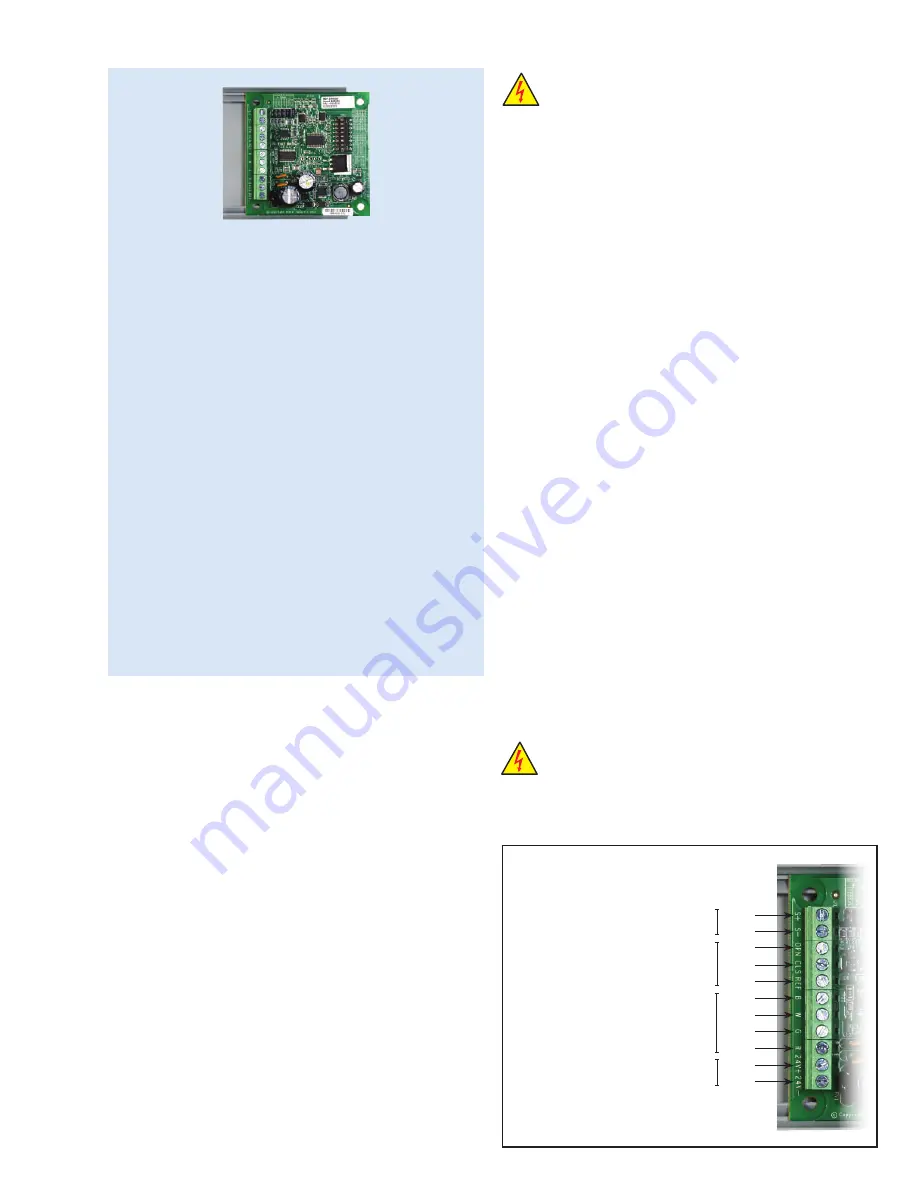

1. Mount the IB-G in a dry, protected location close* to the

24 volt power supply and external controller. The IB-G is

based on a 3.0” x 3.0” (76mm x 76mm) circuit card with

0.170” (4.3mm) mounting holes located at each corner,

2.5” (63.5mm) center-to-center. If desired, these mounting

holes may be used with customer supplied non-metallic

standoffs. The IB-G is supplied with a length of snap-in

plastic track. The track should be mounted in the desired

location with the orientation shown in Figure 1. Note that

the track should be at the top and bottom. Place the board

into the bottom track and then snap the top of the board into

the upper track. Only press on the PCB top edge during

installation, do not press on components or the center of

the PCB. The screw terminals should be located on the left

when facing the IB-G. See Figure 1.

Introduction

The

IB-G

is a small electronic circuit board that

extends the functionality of an external system

controller to drive step motor valves. The external

controller must provide an analog 0-10VDC or

4-20mA signal to the IB-G. The signal is then

converted to a step motor signal to position the valve.

The

IB-G

has been developed with all of the

functionality of the following IB Series Interface

Boards including quick response versions: IB 1, IB

2, IB 3, IB 6 and IB ESX. All of these options are

configurable on the IB-G. The IB-G can accept

4-20 milliamp or 0-10 volt DC analog input signals

and is designed to allow externally supplied control

signals to control one or two Sporlan step motor

valves including CDS evaporator control valves,

SDR electric discharge bypass valves, and SEI/SER/

SEH/SEV/ESX* electric expansion valves. Enhanced

features include LED indicators for power and valve

position, option for 400 pulses per second (pps), and

a valve open or close feature.

*The IB-G can only control a single ESX valve.

Warning: Do not apply power to the IB-G until

wiring is complete. Remove power before making

any wiring changes.

*Voltage drop must be considered when locating the IB-G

away from the power supply and external controller.

2. Digital inputs connected to terminals “OPN”, “CLS” and

“REF” can be used to drive the valve open or closed. A

short between “OPN” and “REF” will open the valve

100%, a short between “CLS” and “REF” will close

the valve. The “OPN”, “CLS” and “REF” terminals, if

used, must be supplied with a “dry” contact from a switch

or relay. No external power should be applied to these

terminals. See Figure 1.

3. Connect valve wires to terminals “B”, “W”, “G” and “R”

(Black, White, Green, Red). See Appendix C – Wiring

Diagram for unipolar valves

.

4. Connect externally supplied control signal (4-20mA or

0-10V) to terminals “S+” and “S-”. See Figure 1 and

Appendix C – Wiring Diagram.

5. Connect power wires to terminals “24V+” and “24V-”.

Do not power up. The 24 volts must be supplied by a 30

VA or 40 VA, Class II, transformer (depending on the

valve type and number of valves per IB-G) not used for

any other purpose. In addition, the secondary winding of

the transformer must not be connected to chassis ground.

A single transformer may be used for multiple IB-G

boards. If a single transformer is used, one leg of the 24

volt supply must be connected to all of the IB-G boards at

the “24V+” terminal. The other leg of the 24 volt supply

must be connected to all of the IB-G boards at the “24V-”

terminal. See Appendix C – Wiring Diagram.

Notes:

• The 24VAC supply polarity is critical when two

IB-Gs are used. See Appendix C – Wiring Diagram.

• Maximum torque on all screw terminals is 3.5 in-lbs.

Warning: Route and secure cables away from

hot surfaces, high voltage lines, and moving

components. Use caution when working around

high voltage components. Safety covers should be

used for personal safety on high voltage panels.

† See

Appendix C – Wiring Diagram for unipolar

valves.

Figure 1

S+

S-

OPN

CLS

REF

B

W

G

R

24V+

24V-

Analog control signal from external controller

to position valve (0-10VDC or 4-20mA)

Dry contact/short from external

controller to force valve open or closed

† Step motor valve

Black, White, Green, Red

24VAC/DC Supply