12

Figure 6

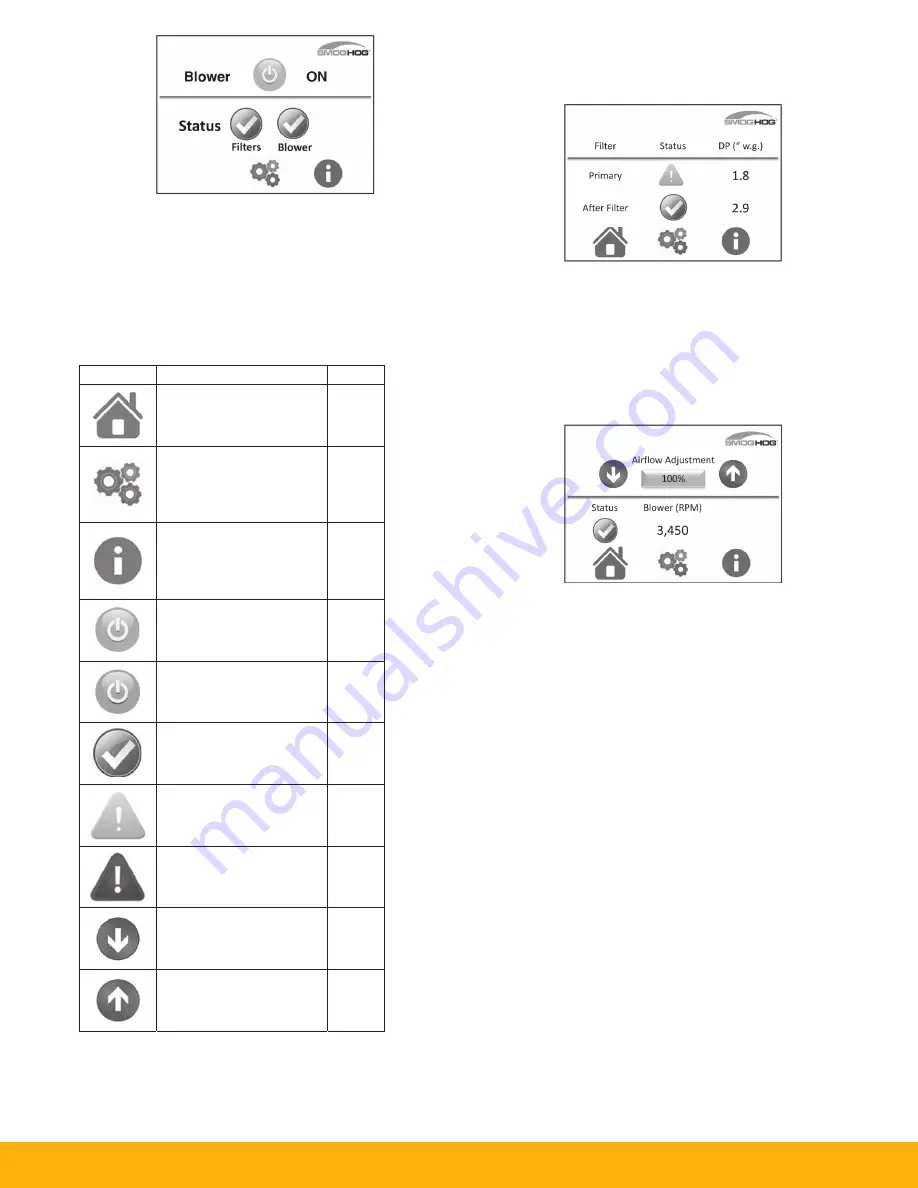

4.3.2 Standard Format

The icon key, Table 3, outlines the various icons that are used on

the screen for various reasons and may indicate status or condi-

tions. The Home, Settings, and Information icons are shown at the

bottom of most screens and will take you directly to their associated

screens. The Status indicator icons are also buttons that will take

you to their associated basic screens as outlined in section 4.3.3.

4.3.3 Basic Screens

Filter Screen:

Figure 7

The Filter screen can be displayed by the operator by selecting

the filter status icon on the Home screen shown in Figure 7. The

Filter screen will then be displayed with all available filters. This

screen will display the differential pressure across the filter during

operation.

Blower Screen:

Figure 8

The standard blower screen will display the status of the

blower. If your equipment is equipped with the Auto-Flow option

and it is activated, the Blower screen will look different than that

shown in Figure 8. Refer to section 4.3.4 for additional details.

The only time the blower will shut down is when the blower has

an internal fault. Such faults as: Low line voltage, phase to phase

issues, ground issues, temperature issues, or for a catastrophic

failure. If the blower shuts down, refer to Section 6 for trouble-

shooting.

On the blower screen you are able to adjust the speed of the

blower using one of two different methods. The first adjustment

can be done using the up/down arrows. This adjustment will

achieve a change of +/- 1%. This will increase or decrease the

airflow adjustment by 1% for each touch of the up or down arrows.

The second method of airflow adjustment is to touch the box that

shows the percentage of the airflow. A number pad will be shown

in a pop up screen. You can enter any number between 20 and

100. This will correspond to the percentage of blower capability.

The blower is capable of 4,200 RPM at 100%, 3150 RPM for 75%,

2100 RPM for 50%, and 1050 RPM for 20%. These number are

approximate and may display slightly differently on any given unit.

There is a minimum set point for speed which is 20% for the pur-

poses of the blower design. The SHM may have multiple blowers

incorporated within the system to support performance of the unit

depending on the customer application. All of these blowers will

respond in unison with the SHM’s controller.

ICON

DESC

The Home

you to the

The Sett

take y

custom

sc

The Info

will tak

custom

conta

Blow

Blower is

mode

Statu

Norma

co

Status =

Operat

norm

Statu

Fault co

needs

Decrea

A

Increas

A

CRIPTION

e icon will tak

e home scree

tings icon will

you to the

mer sengs

creen.

ormaon icon

e you to the

mer service

act screen.

wer is ON

s in STANDBY

and is OFF

s = GOOD

al operang

ndion

= WARNING

ting outside

mal ranges

s = FAULT

ondion that

s aenon

se Speed or

Airflow

se Speed or

Airflow

Color

ke

n.

Blue

Blue

Blue

Green

Y

Blue

Green

Yellow

Red

Blue

Blue

TABLE 3

Icon Key

Summary of Contents for SmogHog SHM-C

Page 1: ...SMOG HOG Media Mist Collector Owner s Manual Models SHM C SHM F...

Page 6: ...Page intentionally left blank...

Page 8: ...4 FIGURE 1B SHM Equipment Description 61 10113 FIGURE 1A SHM Equipment Description...

Page 13: ...9 61 10126 FIGURE 4 Remote Panel Touchscreen Connection...

Page 23: ...19 Figure 6 SHM Replacement Parts SHM 11C SHM 11F...

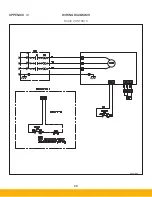

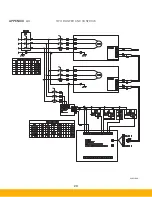

Page 24: ...20 APPENDIX A1 WIRING DIAGRAMS BASIC CONTROLS 04 001682...

Page 25: ...21 REMOTE PANEL BASIC CONTROLS 04 001799 APPENDIX A2...

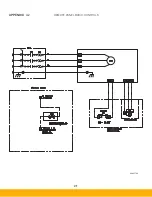

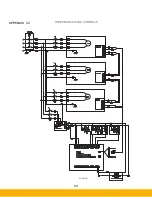

Page 26: ...22 ONE BLOWER AND CONTROLS 04 001695 APPENDIX A3...

Page 27: ...23 TWO BLOWER AND CONTROLS 04 001696 APPENDIX A4...

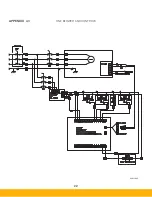

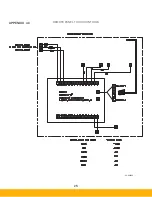

Page 28: ...24 THREE BLOWER AND CONTROLS 04 001697 APPENDIX A5...

Page 29: ...25 REMOTE PANEL TOUCH CONTROLS 04 001802 APPENDIX A6...

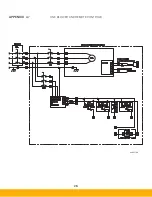

Page 30: ...26 ONE BLOWER AND REMOTE CONTROLS 04 001798 APPENDIX A7...

Page 31: ...27 TWO BLOWER AND REMOTE CONTROLS 04 001797 APPENDIX A8...

Page 32: ...28 THREE BLOWER AND REMOTE CONTROLS 04 001796 APPENDIX A9...

Page 33: ...29 575 480 TRANSFORMER 04 001717 APPENDIX A10...

Page 36: ...32...

Page 37: ...33...