In the event the valve is left disassembled for any length of time,

protecting the components is essential . Place the components

in a polyethylene bag or apply a rust protection agent, such as

refrigerant oil .

Contractors need to follow a WPS (Welding Procedure

Specifcation) for all welding . The procedure must be qualifed and

the welder doing the weld qualifed to perform that procedure .

The codes applicable to the welding of socket weld valves require

that the pipe be inserted into the socket until bottomed against

the stop . The pipe is then to be backed out approximately

1

⁄

16

of an inch before welding . Use of welding rings is optional, but

recommended for butt weld valves . They help alignment, control

gap for full penetration welding, and reduce welding debris entry .

Note:

When welding carbon steel and stainless steel, the welded

joint should be painted to prevent galvanic corrosion .

Socket welding, where allowed, is the preferred connection . This

connection helps to reduce the amount of welding debris in the

piping system .

Remove welding debris and any dirt from the pipes and valve body

before reassembling the valve .

Before putting valves into service, all pipe connections, valve seats,

bonnet seals, and stem seals should be tested for leaks at pressure

levels called for in the appropriate codes .

Installation

All valves are packed for a maximum protection . Unpack carefully .

Check the carton to make sure all items are unpacked . Save the

enclosed instruction for the installer and eventual user .

Do not remove the protective coverings from the inlet and outlet of

the valve until the valve is ready to be installed . Protect the inside

of the valve from dirt and chips before and during installation .

i

Caution

All personnel working on valves must be qualifed

to work on refrigeration systems . If there are any

questions contact Parker Refrigerating Specialties

before proceeding with the work .

The valve should be installed in a location where it is easily

accessible for adjustment and maintenance . The location should

be such that the valve can not be easily damaged by material

handing equipment . When it is necessary to insulate the valve, the

insulation should be installed to provide access for adjustment

and maintenance . Do not insulate solenoid coils . Proper indicating

gauges should be installed to be easily visible to the operating

engineer for system checks and adjustment purposes .

The preferred mounting method for the S8VS series is in the

upright horizontal position .

The valve must be installed with the

arrow pointing in the direction of flow for the valve to function

properly . Prior to welding, protect the inside of the valve body

from welding debris and dirt .

Bulletin 10-02

6

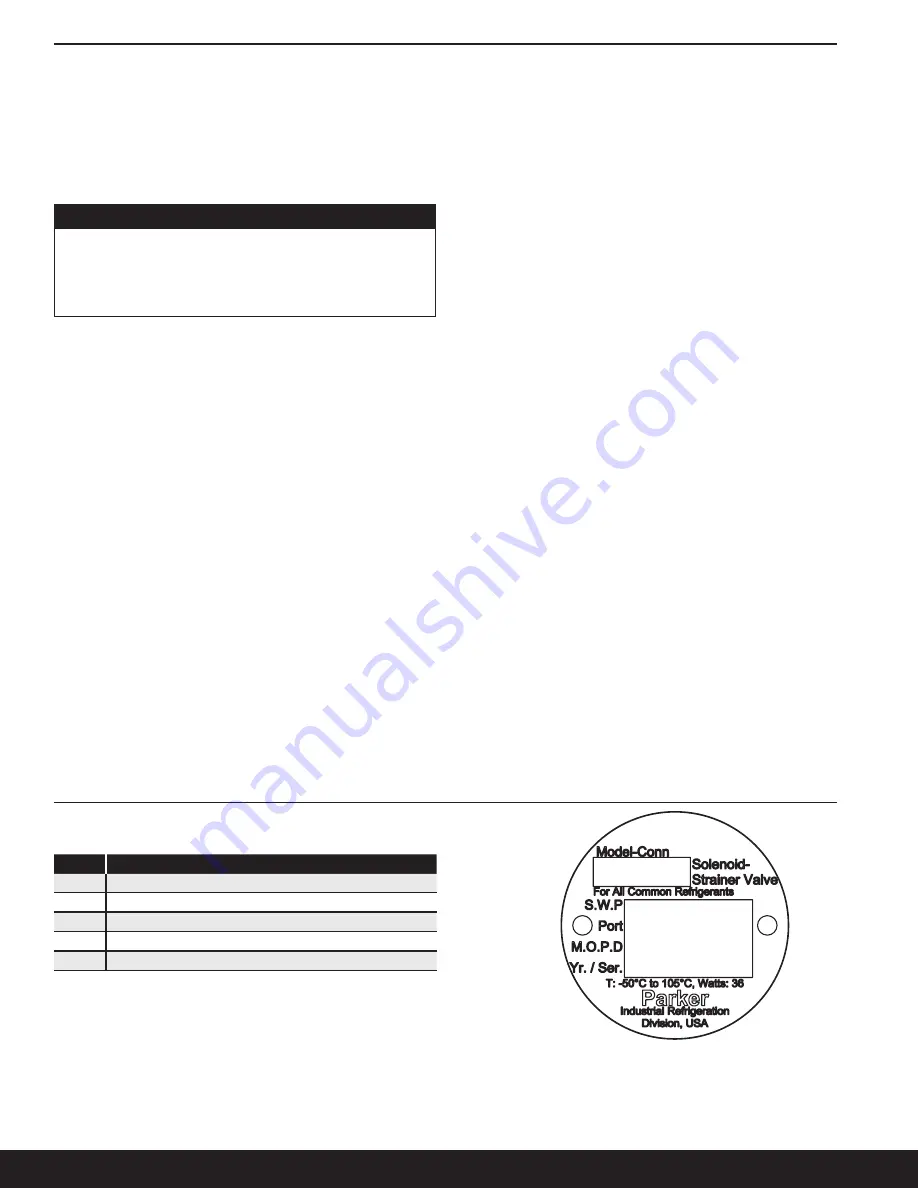

Item

Description

1

Model - Connection Size

2

Safe Working Pressure

3

Port Size

4

Maximum Operating Pressure Differential

5

Year / Serial Number

Nameplate Information

Table 2:

S8VS/S8ST Nameplate Identification

Figure 4:

S8VS/S8ST Nameplate

1

5

4

3

2