11

Crimping pins on cable

6 Assembly

Instruction book, Mounting and maintenance

6

Assembly

Crimping pins on cable

Considerations

Consider the following when mounting connector pins on the harness wires:

•

The crimping of the cable in the connector pin fulfills two functions, to provide a

good electrical connection and to secure the cable mechanically in the connector.

•

A poorly crimped connector pin can work for a while, but will eventually cause spo-

radic functional errors. This type of error can be difficult to identify.

•

Use recommended tools. Using tools other than those from Parker or the connector

manufacturer, or using them improperly, can lead to poorly crimped pins.

Connector wire sealing

Most of the IQAN module connectors require the use of seals where the cable enters

the housing.

Seals are used where the cables are exposed to a harsh environment and there is a risk

that water might enter the cavities of the connector. The silicone seals prevent

corrosion and retain their sealing properties even under conditions of heavy vibrations

and changes in temperature.The seals make the connector less sensitive to moisture and

impurities. The individual wire seals in combination with the face seal (installed in the

module’s connector), create a connection that is weathertight.

Deutsch connector seals accommodate all of the connector wires and are part of the

housing.

Amp/Tyco seals are mounted together with the pin. This is called single wire sealing

because each wire has an individual seal. This type of seal cannot be added after the pin

is crimped.

For satisfactory sealing, the following conditions must be fulfilled:

•

the seals must be faultless. Check for cracks and other damage before mounting

•

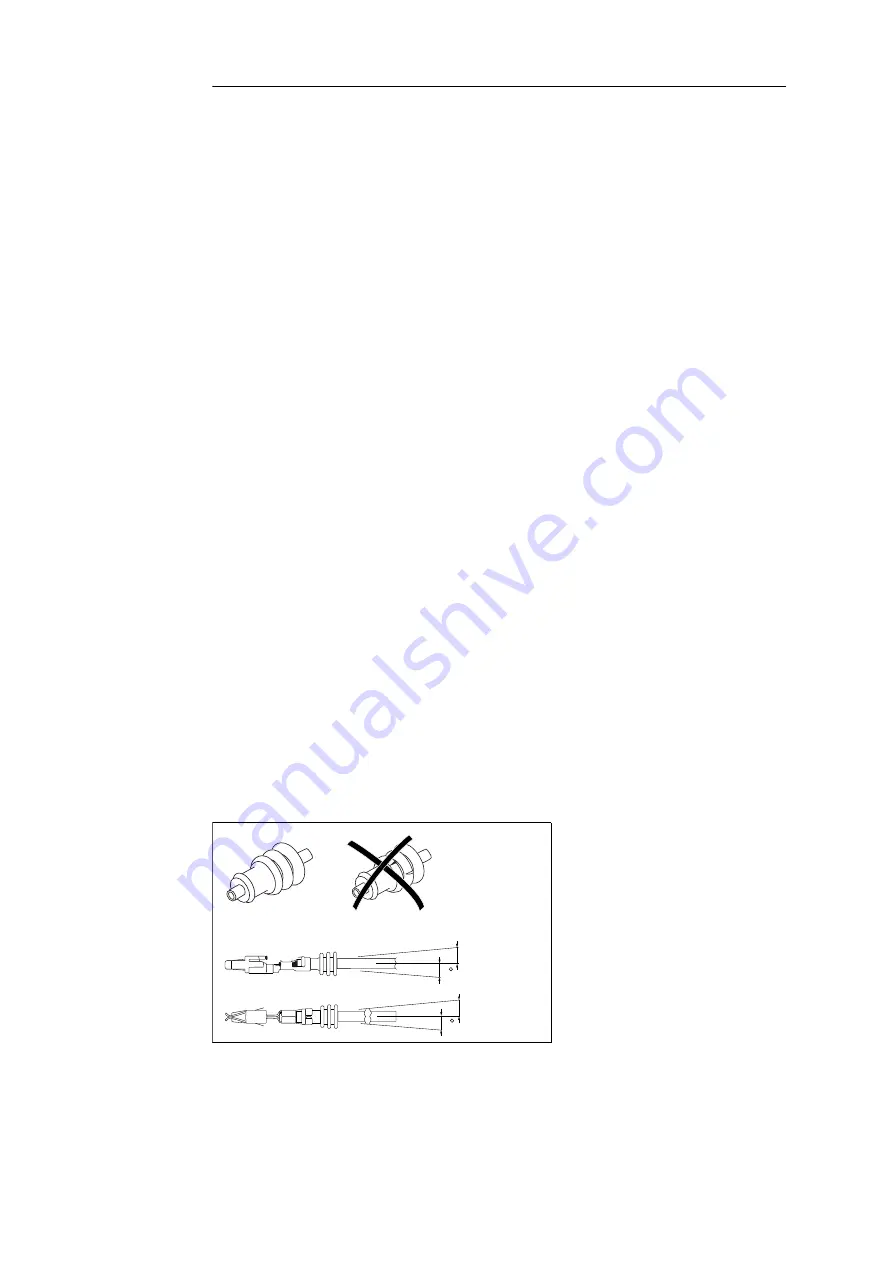

the cable's angle out from the seal must not deviate by more than 5 degrees.

What to look for when seals are used.

5

5