14

WWW.PARKERMOTION.COM

PH: (724)

-

861

-

8200

HMR Series Positioners

7.2

Installation of Linear Drive

All installation measurements can be found under

“6.3

Carrier profile and drive body

”

and in the

HMR catalog.

►

During assembly, the HMR must be sufficiently supported and securely placed in a machine/system.

The maximum straightness and evenness in the running direction of the linear system can only be achieved if

the corresponding mounting points or surfaces are within the required tolerance.

The mounting surface for the profile version must have evenness of at least 0.2 mm/m at the clamping points.

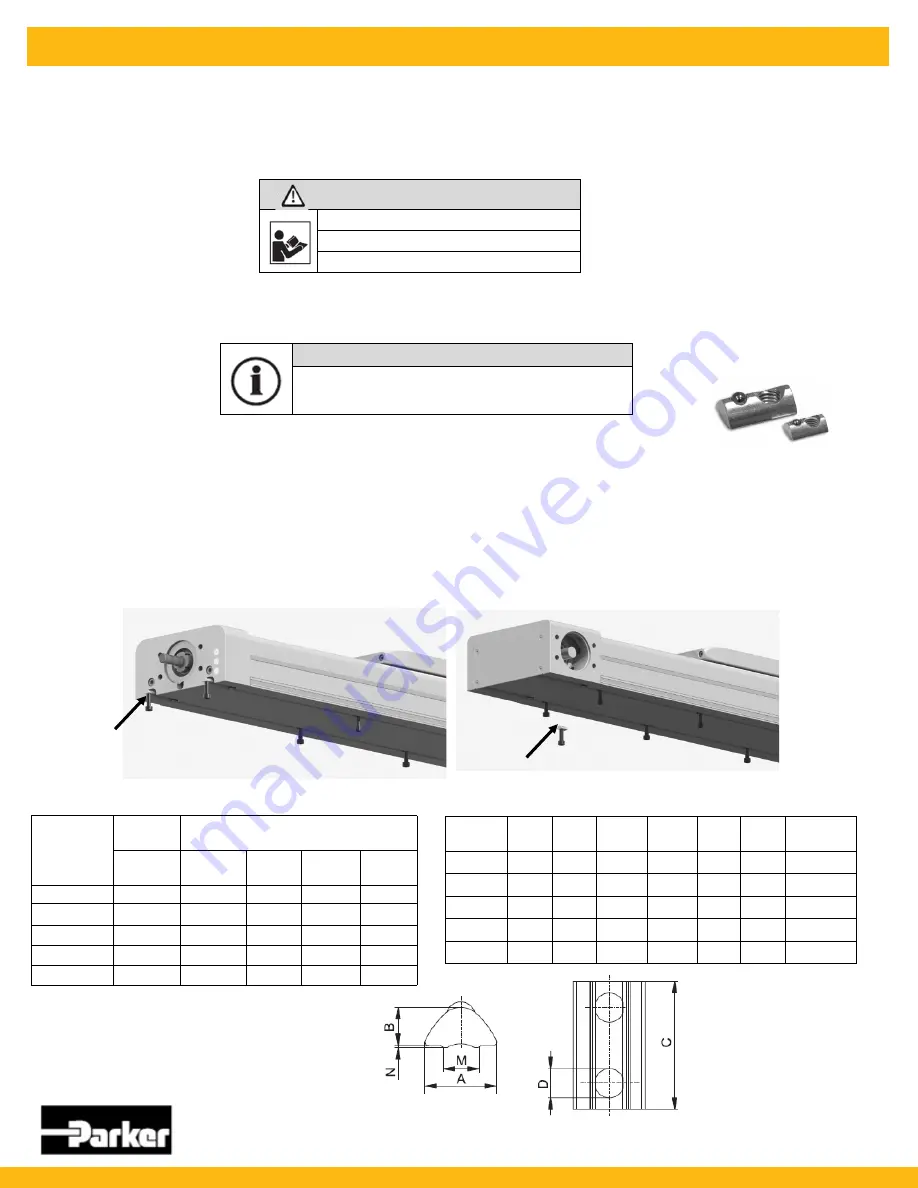

7.2.1

Mounting with T

-

slots

►

Use of T

-

slot profiles. Mounting from below.

Standard screws and sliding blocks or rails from the common profile systems can be used.

Mounting parts such as sliding blocks are available as accessories.

►

Please observe the required number of T

-

sliding blocks in accordance with the axial holding force for

secure assembly (see table below and HMR catalog.

ATTENTION

Straightness tolerance exceeded

The screw

-

on surface is important!

►

Ensure evenness and straightness

NOTE

►

Adhere to the tightening torques for screws according to

section 7.1.

HMRB

T

-

Slot mounting

T

-

Slot mounting

Max, axial holding force per mounting set

Product size

T

-

slot

Min, number of sets required per meter

N

horizontal

horiz,

side

over

head

vertical

HMRx08

1,000

4

11

19

5

HMRx11

1,000

4

11

19

5

HMRx15

1,600

4

5

10

5

HMRx18

2,700

4

5

10

5

HMRx24

3,200

4

4

8

5

Dimension table

-

T

-

slot mounting HMR

Product

A

B

C

ØD

M

N

Order no.

HMRx08

8.0

4.0

11.5

M5

5.0

0.5

56351FIL

HMRx11

8.0

4.0

11.5

M5

5.0

0.5

56351FIL

HMRx15

10.5

6.4

22.5

M6

6.4

0.6

56352FIL

HMRx18

13.5

6.7

22.5

M8

8.5

1.00

56353FIL

HMRx24

16.5

8.9

28.5

M10

10.5

1.00

56354FIL

HMRS